iTSSe

TSS

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

N O V E M B E R / D E C E M B E R

2 0 1 6

4 5

iTSSe

TSS

JTST

HIGHLIGHTS

13

The

Journal of Thermal Spray Technol-

ogy

(JTST),

the official journal of the ASM

Thermal Spray Society, publishes con-

tributions on all aspects—fundamental

and practical—of thermal spray science,

including processes, feedstock manufac-

ture, testing, and characterization. As the

primary vehicle for thermal spray informa-

tion transfer, its mission is to synergize the rapidly advancing

thermal spray industry and related industries by presenting

research and development efforts leading to advancements

in implementable engineering applications of the technology.

Articles from the October and December issues, as selected

by

JTST

Editor-in-Chief Armelle Vardelle, are highlighted here.

The December issue also features the 7th Asian Thermal Spray

Conference (ATSC-7). In addition to the print publication,

JTST

is available online through springerlink.com. For more infor-

mation, visit asminternational.org/tss.

ESTABLISHED AND ADAPTED DIAGNOSTIC

TOOLS FOR INVESTIGATION OF A SPECIAL

TWIN-WIRE ARC SPRAYING PROCESS

Johannes König, Michael Lahres, Stephan Zimmermann,

and Jochen Schein

In a twin-wire arc spray (TWAS) process developed by

Daimler AG, known as LDS (Lichtbogendrahtspritzen), gas in-

jection and arc feed play a crucial role in separating molten

particles from the wire ends. This paper describes an investi-

gation of the gas and particle behavior according to individual

LDSprocessparameters. Coatingproblemsarenot considered.

Measurements are separated into two different parts: Cold

(without arc and particles) and hot (with arc and particles).

Results provide the first detailed understanding of the effect of

different LDS process parameters. A correlation between the

gas parameter settings and the particle beam properties was

found. Using established and adapted diagnostic tools, also

used in conventional TWAS processes, this special LDS process

was investigated and the results (gas and particle behavior)

validated, thereby allowing explanation and comparison of

the diagnostic methods, which is the main focus. Based on

error analysis, individual instabilities, limits, and deviations

during the gas determinations and particlemeasurements are

explained in more detail. The paper concludes with presenta-

tion of the first particle-shadow diagnostic results and main

statements regarding these investigations (Fig. 1).

MANUFACTURING AND PROPERTIES OF

HIGH-VELOCITY OXYGEN FUEL

HVOF)-SPRAYED FeVCrC COATINGS

Paolo Sassatelli, Giovanni Bolelli, Luca Lusvarghi, Tiziano

Manfredini, and Rinaldo Rigon

This paper studies the microstructure, sliding wear be-

havior, and corrosion resistance of high-velocity oxygen fuel

(HVOF)-sprayed FeVCrC-based coatings. Various process pa-

rameters were tested to evaluate their effects on coating prop-

erties, which were also compared to those of HVOF-sprayed

NiCrBSi and Stellite-6 coatings. Fe-alloy coatings are com-

posed of flattened splats, originating from molten droplets

and consisting of a super-saturated solid solution, together

with rounded particles, coming from partially unmolten ma-

terial and containing V- and Fe-based carbide precipitates. All

process parameters, apart from extreme settings with excess

comburent in the flame, produce dense coatings, indicat-

ing that the feedstock powder is quite easily processable by

HVOF. These coatings, with a microhardness of 650-750 HV0.3,

exhibit wear rates of ≈2 × 10

−6

mm

3

/(Nm) in ball-on-disk tests

against sintered Al

2

O

3

spheres. They perform far better than

the reference coatings, and better than other Fe- and Ni-base

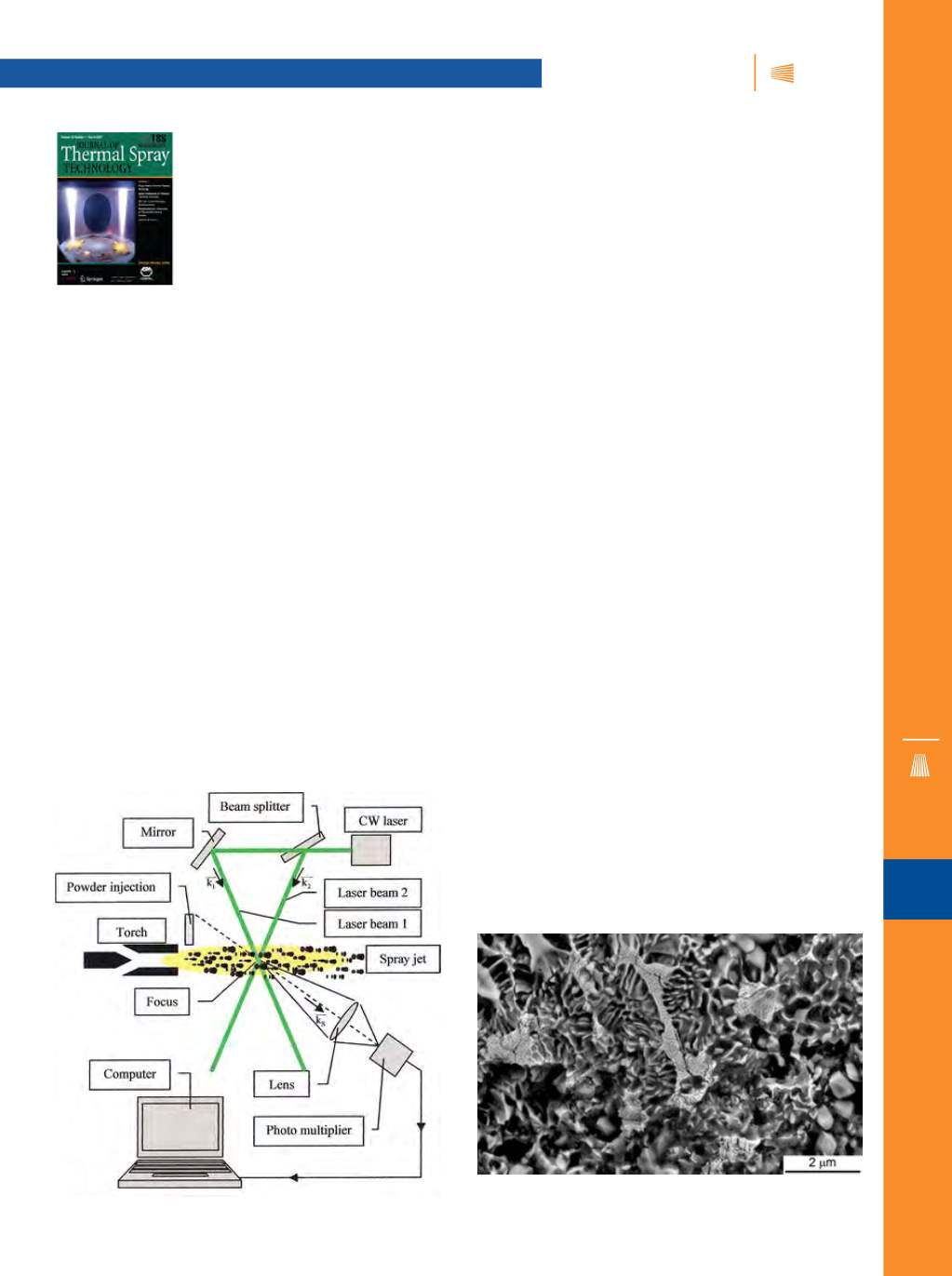

Fig. 1 —

Laser doppler anemometry: Principle of setup.

Fig. 2 —

SEMmicrograph of Sample 1 cross-section after electro-

chemical polarization test.