A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

N O V E M B E R / D E C E M B E R

2 0 1 6

1 9

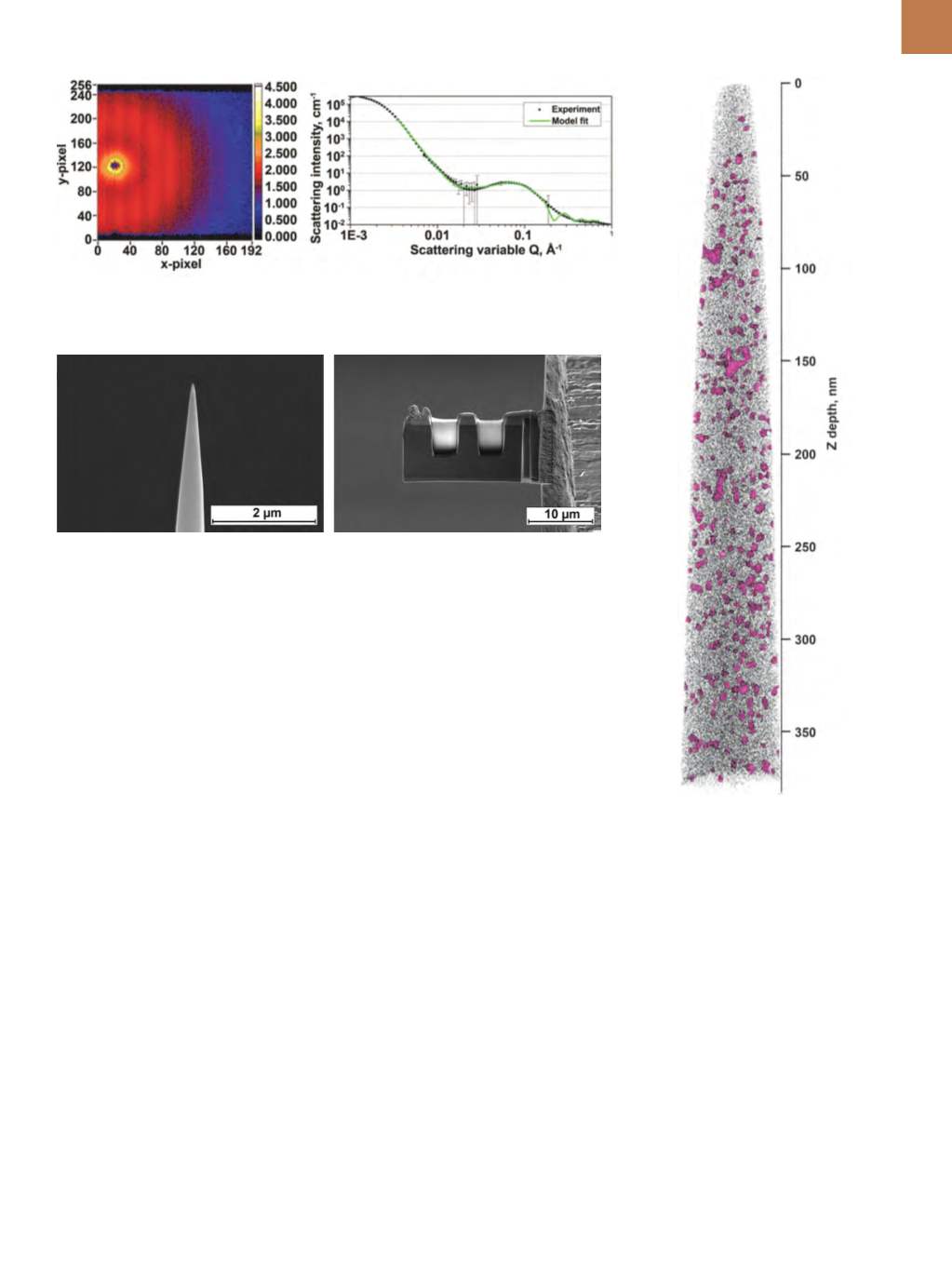

Fig. 2 —

(a) Raw SANS diffractogram for Fe-18Cr-2.9Al alloy, irradiated to 13.8 dpa at 341

°

C.

(b) Final SANS scattering intensity curve, combining data from three distinct detector config-

urations, and example fit of analytical model to the data.

Fig. 3 —

SEMmicrographs of representative Fe-Cr-Al specimens prepared for (a) APT analysis,

and (b) TEM and STEM analysis.

Fig. 4 —

Atomprobe reconstruction

showing precipitate microstructure in Fe-

15Cr-3.9Al alloy, irradiated to 7 dpa at 320°C.

Precipitates are displayed using 34 at.%Cr

concentration isosurfaces (purple) with 2%

of total matrix Fe atoms shown (black).

a diffractogram for the Fe-18Cr-2.9Al

specimen irradiated to 13.8 dpa at 340°C

is shown in Fig. 2a, in which the precip-

itate signal manifests as a red-orange

contrast ring around the central zero-

beam (black contrast). Radial reduction

of these diffractograms to one-dimen-

sional curves allows analytical models

to be fit to the data, from which bulk-

averaged precipitate morphology infor-

mation can be extracted (Fig. 2b).

Sections from the remaining

half-tensile specimens opposite the

strained neck were cut using a low-

speed saw in the hot cells and shipped

to the Low Activation Materials Devel-

opment & Analysis (LAMDA) facility

at ORNL for FIB sample preparation.

LAMDA is a specialized facility designed

for state-of-the-art characterization of

low-radiological threat fuel and metal-

lic specimens

[6]

. Much less material is

required for FIB sample preparation

and subsequent analyses compared

to SANS, and the volume reduction

in the hot cell was sufficient to allow

for out-of-cell hand polishing of speci-

mens in LAMDA using standard metal-

lographic techniques with appropriate

personal protective equipment (PPE)

and dosimetry. Polished specimens

were then installed in a remotely-

operated FEI Quanta 3D Dual-Beam FIB

that is housed in a lead-lined room in

order to shield personnel from radiation

exposure. Operators of FIB equipment

are specially trained to handle the radio-

logical samples and a focus is placed on

efficient loading practices to minimize

exposure to the radioactive specimens.

Standard lift-out techniques

[7]

were

then used to prepare microtip needles

for APT analyses and lamellae for scan-

ning transmission electron microscopy

(STEM) investigations, examples of

which are shown in Fig. 3.

APT investigations allowed for an

atomic-scale study of individual pre-

cipitate composition and morphology

within a very small analysis volume.

Data collection was performed using

the Cameca Instruments Local Elec-

trode Atom Probe (LEAP) 4000X HR at

either the Center for Nanophase Mate-

rials Sciences (CNMS) at ORNL or at the

Center for Advanced Energy Studies

(CAES) at INL. Both facilities are capa-

ble of handling radiological samples,

but the significant volume reduction

(< 100

μ

m

3

on a single APTmicrotip cou-

pon) promotes ease of handling when

working at these laboratories. A repre-

sentative reconstruction of a Fe-15Cr-

3.9Al specimen irradiated to 7 dpa at

320°C is shown in Fig. 4. APT results

reveal that Al additions appear to

reduce the Cr content of precipitates

when compared to binary Fe-Cr alloys

[8]

,

and the observed precipitate morphol-

ogy trends are in agreement with those

seen in the SANS study, validating the

(a)

(b)

(a)

(b)