A D V A N C E D M A T E R I A L S & P R O C E S S E S | N O V E M B E R / D E C E M B E R 2 0 1 6

2 2

L

aser scanning confocal micros-

copy (Fig. 1) provides non-contact,

nanometer level profile (depth)

resolution to measure surface rough-

ness and film thickness data on a vari-

ety of materials and components. This,

along with the possibility of high resolu-

tion and large area mapping, are lead-

ing to new opportunities for materials

characterization.

To measure surface profiles, tra-

ditional contact methods risk surface

damage, particularly for soft materials.

Additionally, surface changes smaller

than the stylus tip cannot be measured

or quantified. A laser microscope can be

used on soft and hard materials alike

because it is non-contact and the laser

beam diameter is much smaller than a

stylus, which provides more accurate

data. The laser also makes it easier to

measure surfaces on an entire area

without the need to properly place a

measuring device (Fig. 2).

Scanning electron microscopy

(SEM) is typically used when resolution

beyond optical microscopy is required.

A key advantage of laser microscopy

compared to SEM is that high resolu-

tion images (with magnifications up

to 28,000×) are possible in air with-

out additional surface preparation.

This makes laser microscopy a faster

option for imaging materials and com-

ponents. With an automated stage and

image stitching capabilities, large-area

high-resolution images can be obtained

ADVANTAGESOF 3D LASER

SCANNINGCONFOCAL

MICROSCOPY

3D laser microscopy is opening new areas of study for metallic

alloys and coatings in power generation applications.

John Shingledecker,* John Siefert, and Daniel Purdy,* Electric Power Research Institute, Charlotte, N.C.

Jonathan Tedesco and Andrew Szafarczyk, Keyence Corp., Itasca, Ill.

*Member of ASM International

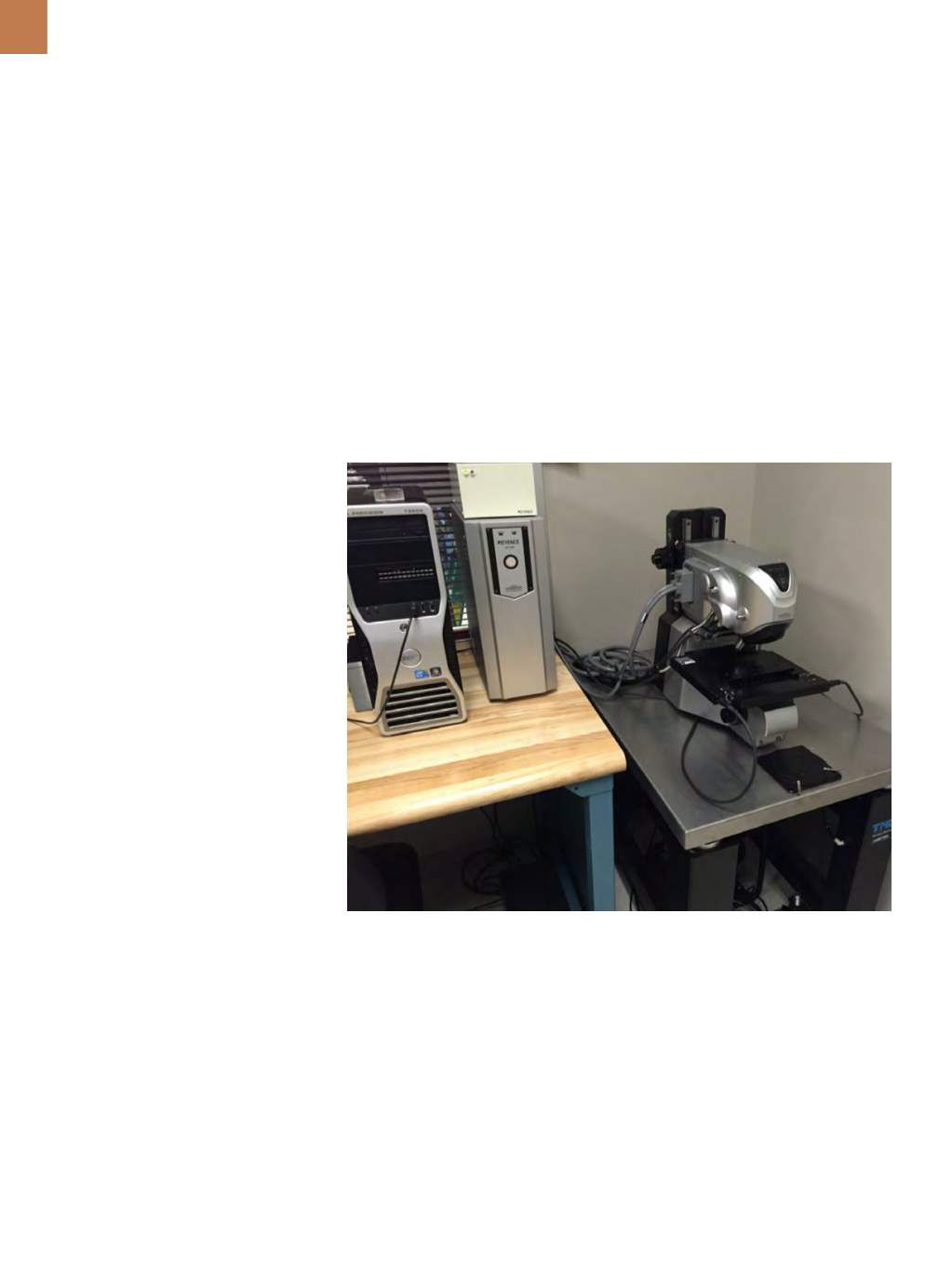

Fig. 1 —

Keyence VK-X laser microscope.

while retaining spatial distances and

associated 3D depth information,

which is not possible with a SEM.

Laser microscopy is used in a vari-

ety of industries. The ability to measure

depth and soft/optical materials in a

non-contact manner is particularly well

suited for the electronics industry and

chemical industries including a wide

range of applications in CCD micro-

lens characterization, MEMs measure-

ments and failure investigations, silicon

wafer roughness, and film thickness

characterization of transparent mate-

rials such as glasses and lenses. Laser

microscopy is also widely used for met-

als characterization, specifically surface

roughness. In addition, the unique attri-

butes of the laser microscope have led to

expanded characterization applications

for materials in power generation equip-

ment in recent years.

CASE STUDIES

At the Electric Power Research

Institute’s (EPRI) laboratories in Char-