A D V A N C E D M A T E R I A L S & P R O C E S S E S | N O V E M B E R / D E C E M B E R 2 0 1 6

1 8

designing a nuclear-grade Fe-Cr-Al alloy

for LWR cladding applications.

To this end, neutron irradiation

and PIE analysis studies were per-

formed on four Fe-Cr-Al model alloys

with nominal compositions ranging

from 10-18 wt% Cr and 2.9-4.8 wt% Al.

Alloy compositions, as determined by

inductively coupled plasma optical

emission spectroscopy (ICP-OES), are

shown in Table 1. These materials were

machined into SS-J2 sub-sized tensile

specimens

[5]

and irradiated in HFIR to

various nominal damage doses up to

13.8 displacements per atom (dpa)

at a target temperature of 320

°

C, cor-

responding to a maximum exposure

time of approximately 4900 hrs. Dpa

commonly describes radiation damage

and is defined as the average number

of times an atom is displaced from a

lattice site for a given fluence of ener-

getic particles. Dpa is calculated based

on the fluence and energy spectrum

of incident particles for a given mate-

rial. The specimens in the 13.8 dpa

condition are expected to provide a

reasonable approximation of material

properties and microstructure at the

end of the typical LWR fuel cladding

lifetime. Details of final irradiation con-

ditions are shown in Table 2.

Following irradiation, an assess-

ment of tensile behavior was performed

using room temperature and elevated

temperature tensile testing with sub-

sequent scanning electron microscopy

(SEM) fracture surface analysis in-cell

at the Irradiated Materials Examination

and Testing (IMET) Hot Cell Facility at

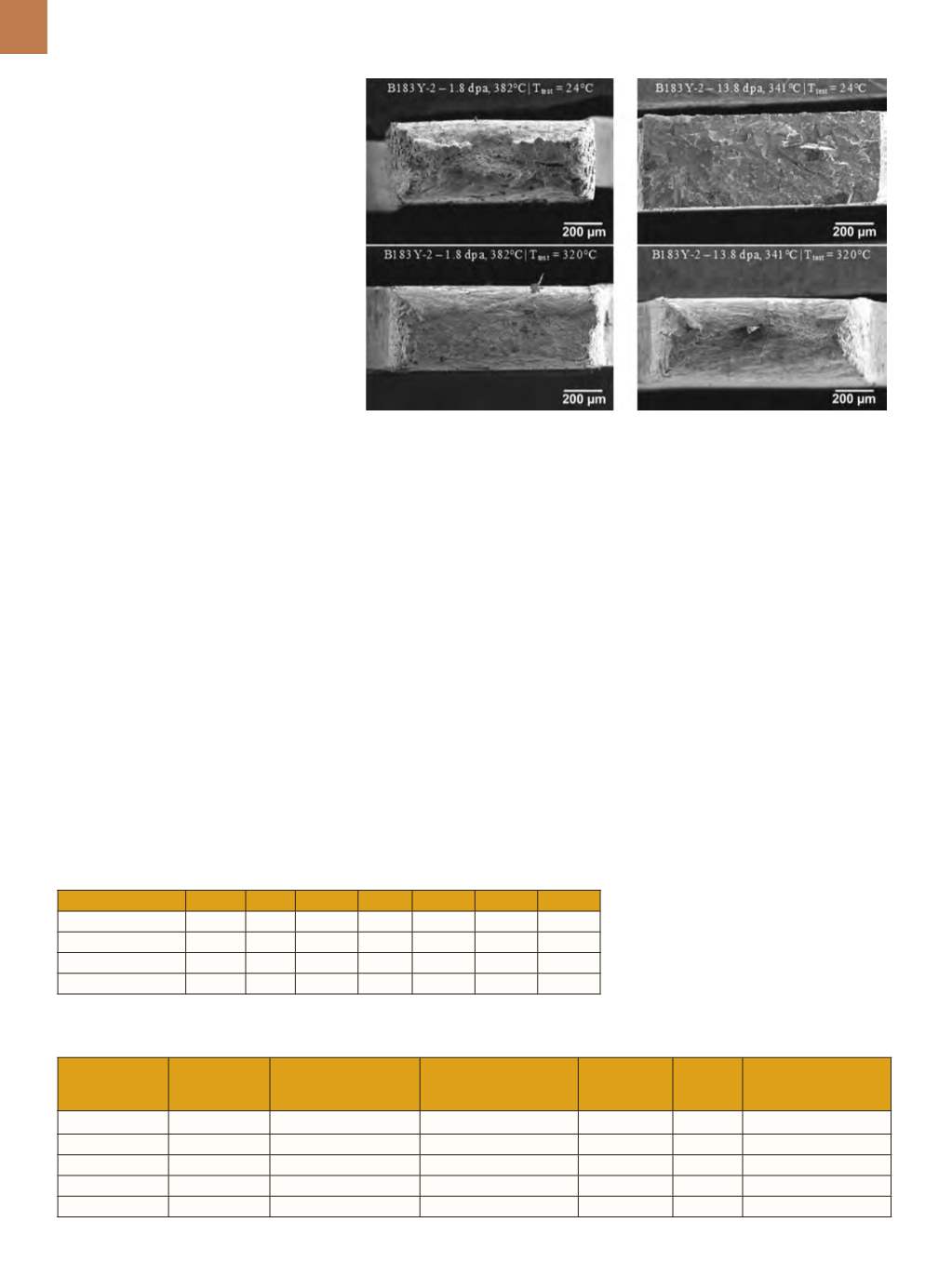

ORNL. Fractographs for a low- and high-

dose condition of the Fe-18Cr-2.9Al fol-

lowing room temperature tensile tests

demonstrate clear differences in speci-

men failure mode (Fig. 1a-b), with typ-

ical dimple ductile fracture observed at

early-life doses transitioning to brittle,

transgranular cleavage fracture at end-

of-life doses. Tensile tests performed at

320°C after irradiation demonstrated

ductile failure mechanisms in all dose

conditions studied (Fig. 1c-d).

Broken half-tensile heads from

each material condition were then pre-

pared, packaged for on-road shipping,

and shipped to the general purpose

small-angle neutron scattering (SANS)

beamline at ORNL for diffraction-based

analysis of nanoscale

α

ʹ precipitates in

the microstructure. SANS is a nonde-

structive analysis technique in which

an incident beam of neutrons is elas-

tically scattered by interactions with

nuclei or with the magnetic moment of

unpaired electrons. Bulk samples used

here (volume ~8 mm

3

) pose a signifi-

cant radiological threat, so special care

is taken during SANS investigations to

minimize user interaction. These larger

specimens are necessary in order to

fit the 4-mm-diameter aperture sizes

and allow for sufficient scattering to

maintain an adequate signal-to-noise

ratio in the SANS data. Two dimen-

sional diffractograms were collected

at room temperature at three different

detector configurations. An example of

TABLE 1

—

Fe-Cr-Al MODEL ALLOY COMPOSITIONS

INVESTIGATED IN THIS RESEARCH

Alloy

Fe Cr

Al

Y

C

Si

Fe-10Cr-4.8Al

wt% bal.

10.01 4.78 0.038 0.005 <0.01

Fe-12Cr-4.2Al

wt% bal.

11.96 4.22 0.027 0.005 0.01

Fe-15Cr-3.9Al

wt% bal.

15.03 3.92 0.035 0.005 0.01

Fe-18Cr-2.9Al

wt% bal.

17.51 2.93 0.017 0.005 <0.01

*S, O, N, and P contents at or below 10 ppm.

TABLE 2

—

SUMMARY OF Fe-Cr-Al ALLOY CAPSULE IRRADIATION CONDITIONS

Capsule ID

Exposure

time

(hours)

Neutron flux

(n/cm

2

s)

E > 0.1 MeV

Neutron fluence

(n/cm

2

)

E > 0.1 MeV

Dose rate

(dps/s)

Dose

(dpa)

Irradiation

temperature

(°C)

FCAY-01

120

8.54 × 10

14

3.69 × 10

20

7.7 × 10

-7

0.3

334.5 ± 0.6

FCAY-02

301

8.54 × 10

14

9.25 × 10

20

7.7 × 10

-7

0.8

355.1 ± 3.4

FCAY-03

614

8.84 × 10

14

1.95 × 10

21

8.1 × 10

-7

1.8

381.9 ± 5.4

FCAY-04

2456

8.74 × 10

14

7.73 × 10

21

7.9 × 10

-7

7.0

319.9 ± 12.7

FCAY-05

4914

8.74 × 10

14

1.55 × 10

22

7.8 × 10

-7

13.8

340.5 ± 25.7

Fig. 1 —

Comparison of fracture surfaces for Fe-18Cr-2.9Al alloy irradiated to 1.8 dpa (early life)

and 13.8 dpa (near end-of-life) conditions.

(a)

(b)

(c)

(d)