A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

N O V E M B E R / D E C E M B E R

2 0 1 6

2 3

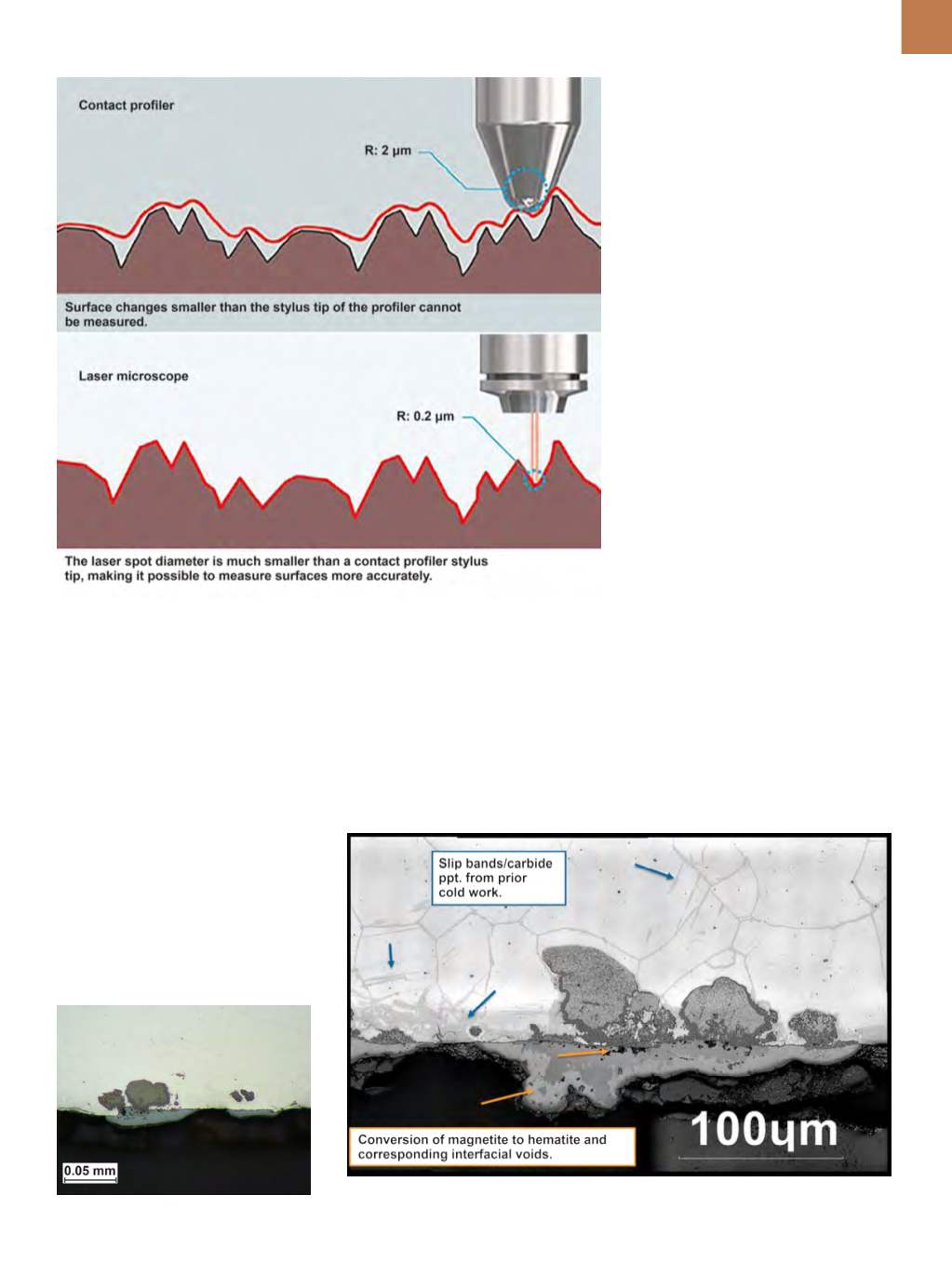

for ~24,500 hours. Using careful sample

preparation including a final ~20 hour

vibratory polishing step, the optical

image of the ID oxide scale was pro-

duced in Fig. 3a.

Internal and external oxidation

in the form of nodules is clearly evi-

dent. However, little information about

grain structure and oxide morphology

is revealed, which is critical to under-

standing material behavior. Chemical

etching could be used to evaluate such

features, but experience shows this

leads to artifacts in the oxide scales.

Using the same as-polished sample and

the laser microscope, large area and

small area high-resolution images were

obtained including detailed charac-

terization of nodule regions. Figure 3b

shows results at approximately 2000×.

On the as-polished material, the grain

structure of steel is observed.

Furthermore, slip bands are evi-

dent from the original SP process as

well as clear evidence of multiple oxide

scale morphologies and voids form-

ing at the inner and outer oxide sur-

face. Comparing Figs. 3a and 3b clearly

shows that the laser microscope offers

enhanced possibilities for detailed

understanding of materials without

the need for surface etching, which can

damage scales and potentially lead to

erroneous results.

Fig. 3a —

Optical image of steam-side scale.

Fig. 3b —

Unetched (as-polished) laser image of the inner diameter surface of a shot-peened

304 H stainless steel superheater tube after ~24,500 hours of service.

Fig. 2 —

Comparison between contact profiler and laser microscope.

lotte, N.C., a Keyence VK-X160K has

augmented, and in some cases re-

placed, metallic alloy characterization

traditionally done using either opti-

cal microscopy or scanning electron

microscopy. The VK-X160K uses a red

semiconductor laser (658 nm wave-

length) with maximum z-axis (depth)

display resolution of 5 nm, maximum

magnification of 19,200×, and motor-

ized x-y stage with a range of 100 × 100

mm. The microscope’s ability to show

subtle differences in surface relief, de-

velop high-resolution large area met-

allurgical maps, and quantify surfaces

through non-contact profilometry has

opened up new avenues in research.

Inner diameter (ID) shot-peening

(SP) of austenitic stainless steel boiler

superheater (SH) tubing has been used

to manage short-term (<10,000 hour)

steam-side oxidation and exfoliation

in utility boilers

[1]

. To improve under-

standing of long-term behavior of this

technique, EPRI received SP-304H SH

tubing after exposure in a utility boiler