A D V A N C E D M A T E R I A L S & P R O C E S S E S | N O V E M B E R / D E C E M B E R 2 0 1 6

2 4

profilometry techniques that generally

provide a single 2D trace, which pro-

vides a linear profile or maximumdepth

of damage. Alternatively, a laser micro-

scope can rapidly provide a detailed 3D

topography map of the entire specimen

and enable valuable and quantifiable

parameters to be determined. Exam-

ples of these parameters include maxi-

mumand average depth of damage and

total volume lost, as well as various sur-

face textures such as adhesion.

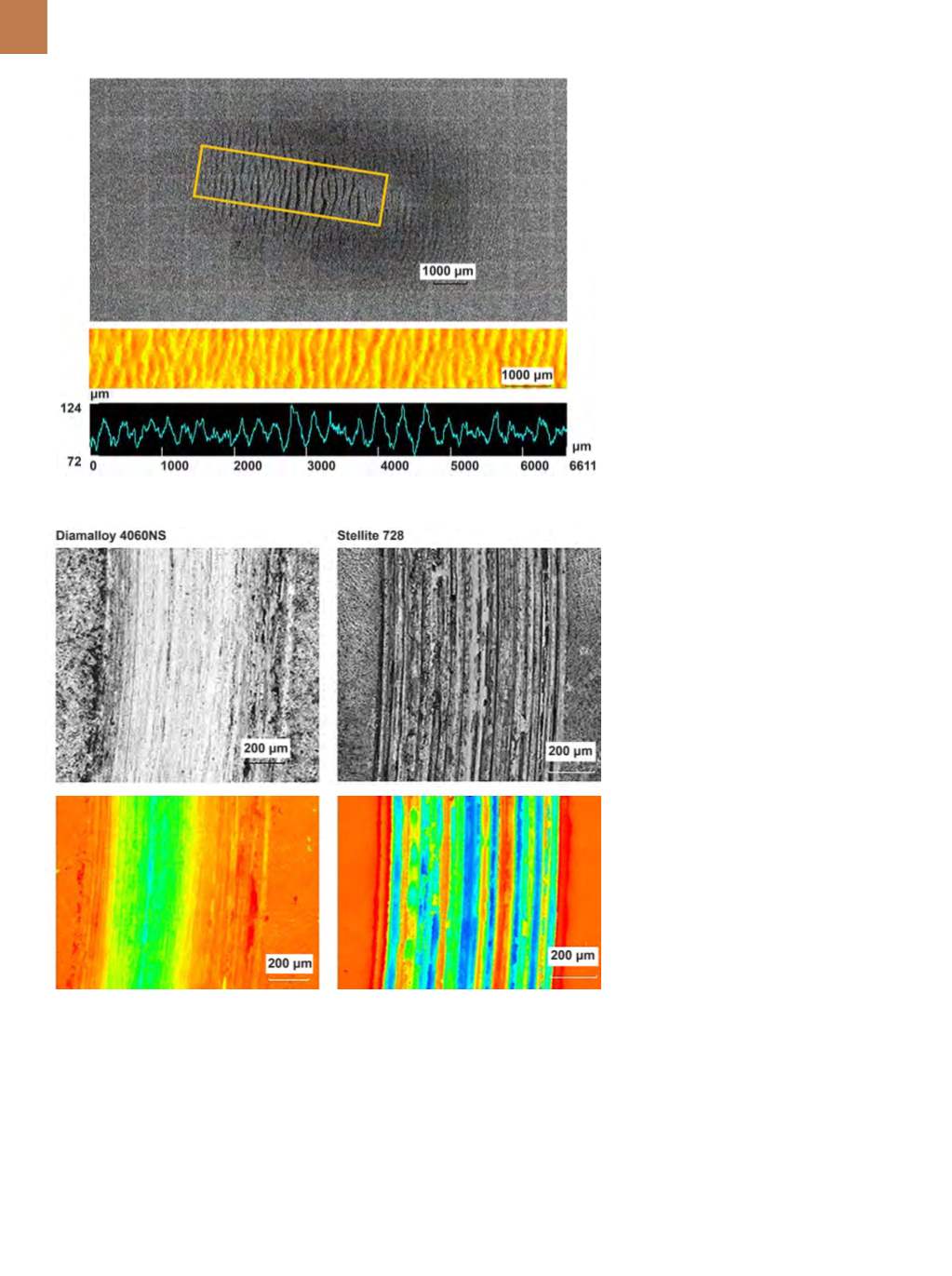

In solid particle erosion, 3D scan-

ning via laser microscopy was used to

quantify the above parameters in sup-

port of development of the ASTM G211

high-temperature erosion test stan-

dard

[2]

. In addition, the level of detail

from laser microscopy can illuminate

topographical features that may be

relevant to the success or failure of a

material or related to the test equip-

ment’s inconsistencies. Analysis of the

sample in Fig. 4 shows surface pertur-

bations forming a series of ripples. In

this case, comparisons between the 3D

laser images and 2D contact methods

found that traditional 2D methods can

under or overestimate actual metal ero-

sion rates by more than 20%.

In elevated temperature sliding

wear for advanced cycle power gen-

eration, various hardfacing materials

behave differently as illustrated in

Fig. 5. Here, the Diamalloy 4060NS

HVOF spray coating shows a consis-

tent low wear rate while the Stellite 728

experimental GTAW cobalt alloy shows

significant gouging and adhesion under

the same test conditions. The 3D height

maps produced from laser microscopy

can be used to reliably quantify these

differences. In fact, research using

these techniques has shown that cur-

rent ASTM standards that only rely on

optical comparisons can be explained

in quantifiable terms

[3]

.

EVALUATING EROSION

DAMAGE

Erosion damage in steam turbine

valve stems presents a reliability chal-

lenge to utilities. Steam-grown oxides

appearing on the inside surfaces of

high-temperature boiler tubes and

pipes occasionally exfoliate and are

entrapped in the steam system. In the

Fig. 4 —

High resolution 3D color height map used to characterize a high-temperature erosion

test coupon.

Fig. 5 —

Quantifiable differences in high temperature wear behavior of potential high-temperature

wear resistant coatings/claddings for valves after high-temperature laboratory wear testing.

LASER MICROSCOPY FOR

HARDFACING ALLOYS

Tribology is the science of interac-

tions between two bodies. In general,

these interactions damage one or both

components. Characterizing the rate of

how this damage accumulates is criti-

cal for providing materials comparisons

under expected service conditions. EPRI

has been studying advanced hardfacing

alloys for high-temperature valves and

alternative materials and coatings for

erosion resistance.

The value of laser microscopy in

tribological examinations is that the

microscope can quickly provide infor-

mation above and beyond traditional