A D V A N C E D M A T E R I A L S & P R O C E S S E S | N O V E M B E R / D E C E M B E R 2 0 1 6

3 0

teemed into a machine that channeled

the metal through a container where

it solidified and was prepared for the

rolling mills. This process replaced the

casting of metal into large molds and

reducing them by forging or rolling in

preparation for the finishing mills.

LOFTY PROJECTS AMID

RISING IMPORTS

In 1961, Bethlehem Steel built a

central research laboratory to compete

with USS who had built its own lab in

1957. Bethlehem built a huge campus

on 1000 acres bulldozed from a moun-

tain. The $35 million project—eight

buildings and a reflecting pool—was

not complete until 1969. It accommo-

dated over 1000 research engineers

and support personnel and was named

Homer Research Laboratory after Beth-

lehem’s chairman, Arthur B. Homer.

From 1960 to 1970, imports

increased from 8% to 17% of total

U.S. steel consumption. Most of the

imported steel came from Japan, which

had increased production from 25 mil-

lion to 100 million tons annually from

nine new plants located at tidewater

ports for ease of importing raw materi-

als and exporting finished product.

In 1964, Bethlehemdecided tobuild

a new mill at Burns Harbor, Ind., featur-

ing a newproduction layout and state-of-

the-art equipment. It became the most

efficient in the country. The first phase

of construction was limited to finishing

operations and ingots were shipped in

from Johnstown and Lackawanna. Blast

furnaces and BOFs were added later to

make it a fully integrated plant.

CONSOLIDATIONS

AND LAYOFFS

The first integrated steel company

to be affected by the new market with

increasing imports was J&L. They sold

an interest in the company in 1968 to

a Texas conglomerate, Ling-Temco-

Vought (LTV)—who had zero experi-

ence in owning a steel mill. A few years

later, the company completed total

ownership of J&L and called it the LTV

Steel Division. Thus, J&L became the

first casualty in the decline of the inte-

grated steel industry. The next com-

pany to disappear from the industry

was Youngstown Iron Sheet and Tube

Co. (YS&T). It closed the Campbell plant

in Youngstown in the late 1970s and

terminated 5000 employees. In 1979,

it sold all remaining plants to LTV and

joined J&L in the LTV Steel Division.

Though the winds of change had

turned, both USS and Bethlehem built

new corporate headquarters in the

early 1970s. USS was first, construct-

ing a $50 million, 64-story office in

downtown Pittsburgh. In 1972, Bethle-

hem built Martin Tower in Bethlehem,

Pa., named for its chairman, Edmund

Martin. The new 21-story tower cost

$35 million. The same year, Bethle-

hem had peak production of 16 million

tons of finished product and earnings

of $200 million. Employment reached

120,000 in the mid 1970s, but 20 years

later only 20,000 workers remained.

USS closed its Youngstown plant

in 1979, a plant with open hearth fur-

naces and finishing mills as old as 1900

and a sheet mill installed in 1935. It had

become obvious that the mills were too

outdated to compete in the newmarket

conditions.

Bethlehem finally built a continu-

ous caster at Burns Harbor in 1975 after

abandoning its first attempt to continu-

ous cast slabs in 1969 at the Johnstown

plant. At this time, the Japanese were

continuous casting 46% of their steel

capacity compared with 11% for the

U.S. integrated steel industry. Foreign

imports held steady at roughly 15%

during the 1970s, but increased to 22%

during the next decade.

In 1977, Bethlehem reported a

loss of nearly $500 million and began

closing parts of the Johnstown and

Lackawanna plants. The company ter-

minated 2500 white-collar workers that

year, 800 from the Homer Research Lab-

oratory and Martin Tower facilities built

just seven years earlier.

For more information:

Charles R.

Simcoe can be reached at crsimcoe1@

gmail.com.

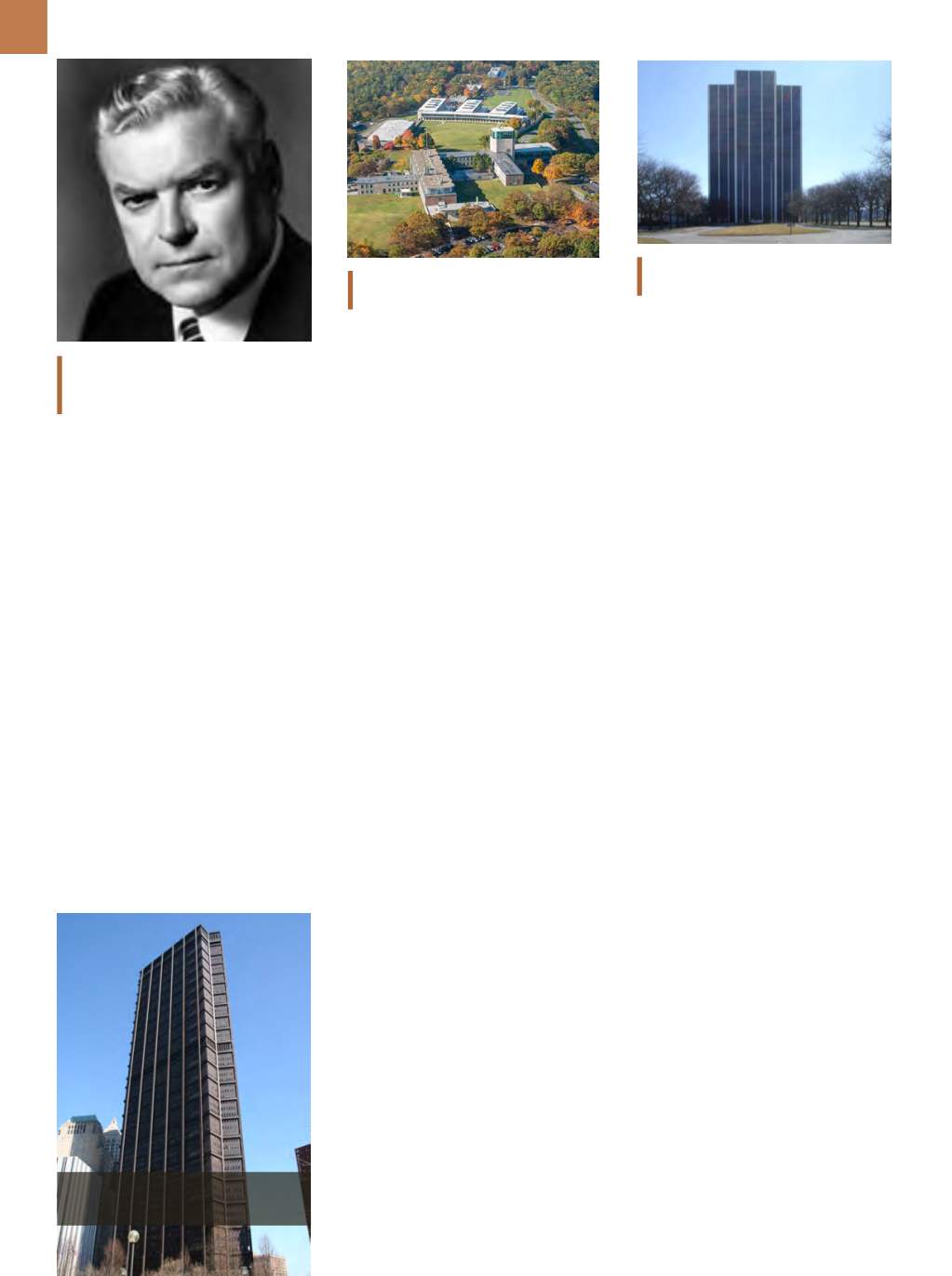

David J. McDonald, president of the steel-

workers union during the strike of 1959.

Courtesy of usw.org.

Bethlehem Steel’s Homer Research

Laboratory. Courtesy of lehigh.edu.

Martin Tower, headquarters of Bethlehem

Steel in Bethlehem, Pa.

U.S. Steel corporate headquarters

in downtown Pittsburgh.