A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

N O V E M B E R / D E C E M B E R

2 0 1 6

2 5

valve stem, the combination of small

hard oxide particles and high veloci-

ties can cause severe erosion damage

in certain cases. Utilities and EPRI have

been investigating material options for

reducing the severity of erosion dam-

age to extend maintenance intervals.

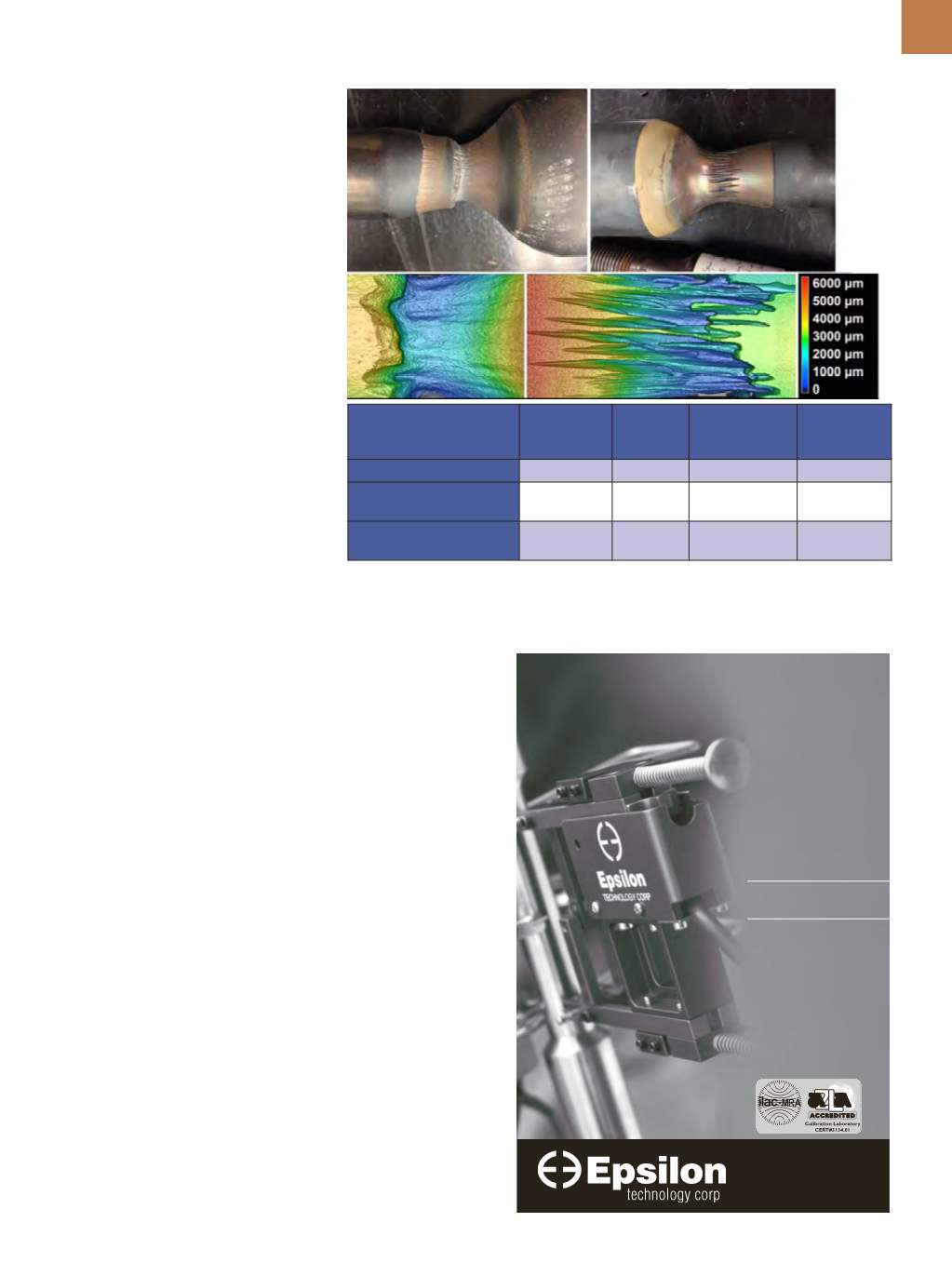

Figure 6 compares two valve stems

from the same unit after nominally

equivalent operating history (hours,

starts, and cycles). In this case, the large

depth of field of the laser microscope

was used to quantify both the amount

and depth of metal loss after service

due to localized erosion. The data

shows 1.6 to 2.4 times improvement

in performance for a valve stem that

included a ~30

μ

m thick, nanostruc-

tured TiSiCN coating. Without a tool like

the laser microscope, quantification of

materials performance would not be

possible due to the tortuous nature and

large area of the erosion damage.

FUTURE POSSIBILITIES

3D laser microscopy is opening new

areas of study for metallic alloys and

coatings in power generation applica-

tions. Further studies are currently being

conducted to quantify creep void distri-

butions in large creep samples and ser-

vice-exposed components on unetched

samples, examine deformation charac-

teristics of small sample tests includ-

ing identification of size and location of

cracking to build more accurate models

of material behavior, and examine hard-

ness indents toaccuratelymeasuredepth

andchanges insurfaceprofiles. The rapid,

accurate, and high resolution quantifica-

tion of materials is a unique combination

that is hoped to be exploited in other

areas to replace or augment optical and

scanning electron microscopy and elimi-

nate the need for 2D surface contact sur-

face profilometry.

~AM&P

For more information:

John Shingle-

decker is senior programmanager, cross

sector technologies, Electric Power

Research Institute, 420 Hillview Ave.,

Palo Alto, CA 94304, 704.595.2619, jshin-

gledecker@epri.com,

www.epri.com.

References

1. A.S. Sabau, et al., Managing Oxide

Scale Exfoliation in Bilers with TP347H

Superheater Tubes,

Advances in Mate-

rials Technology for Fossil Power Plants

,

Fig. 6 —

Laser microscope measurements on large steam turbine valve stems after service com-

paring performance of uncoated and coated stems after nominally equivalent operating history.

Extensometers Strain measurement for materials testing Compatible with all major test systems • Measuring ranges from 1% to 2000% strain • Gauge lengths from 0.125 to 10+ inches (3 to 250+ mm) • Temperature ranges from -265 to 1600°C • Laser extensometers 3975 South Highway 89 Jackson, WY 83001 USA 307 733-8360 www.epsilontech.com Over 30 models to cover all common tests ISO 170252013.15 AMP Dir b&w ad_2002.02 ad 1/2/14 10:41 AM Page 1

Proceedings from the

Seventh International

Conference, Oct. 22-25,

2013, Waikoloa, Hawaii.

Published by ASM Inter-

national, p 821-831,

2014.

2. V.P. Swaminathan, J.S.

Smith, and D.W. Gandy,

High-Temperature Solid

Particle Erosion Testing

Standard for Advanced

Power Plant Materials

and Coatings,

Advances

inMaterials Technology

for Fossil Power Plants

,

Proceedings from the

Seventh International

Conference, Oct. 22-25,

2013, Waikoloa, Hawaii.

Published by ASM Inter-

national, 2014.

3. J. Siefert and S. Babu,

Experimental Observa-

tions of Wear in Spec-

imens Tested to ASTM

G98,

Wear,

Vol 320, p

111-119, 2014.

Area

measured

(mm

2

)

Eroded

volume

(mm

3

)

Eroded volume

per 100 mm

2

(mm

3

)

Average

depth

of erosion

Old stem (no coating)

49

303

618

6.2

Stem with 30 micron

thick nanocoating

75

194

259

2.6

Improvement in erosion

resistance due to coating

1.6

2.4

2.4

Uncoated stem after service

Nanostructured coating after service