A D V A N C E D M A T E R I A L S & P R O C E S S E S | N O V E M B E R / D E C E M B E R 2 0 1 6

2 0

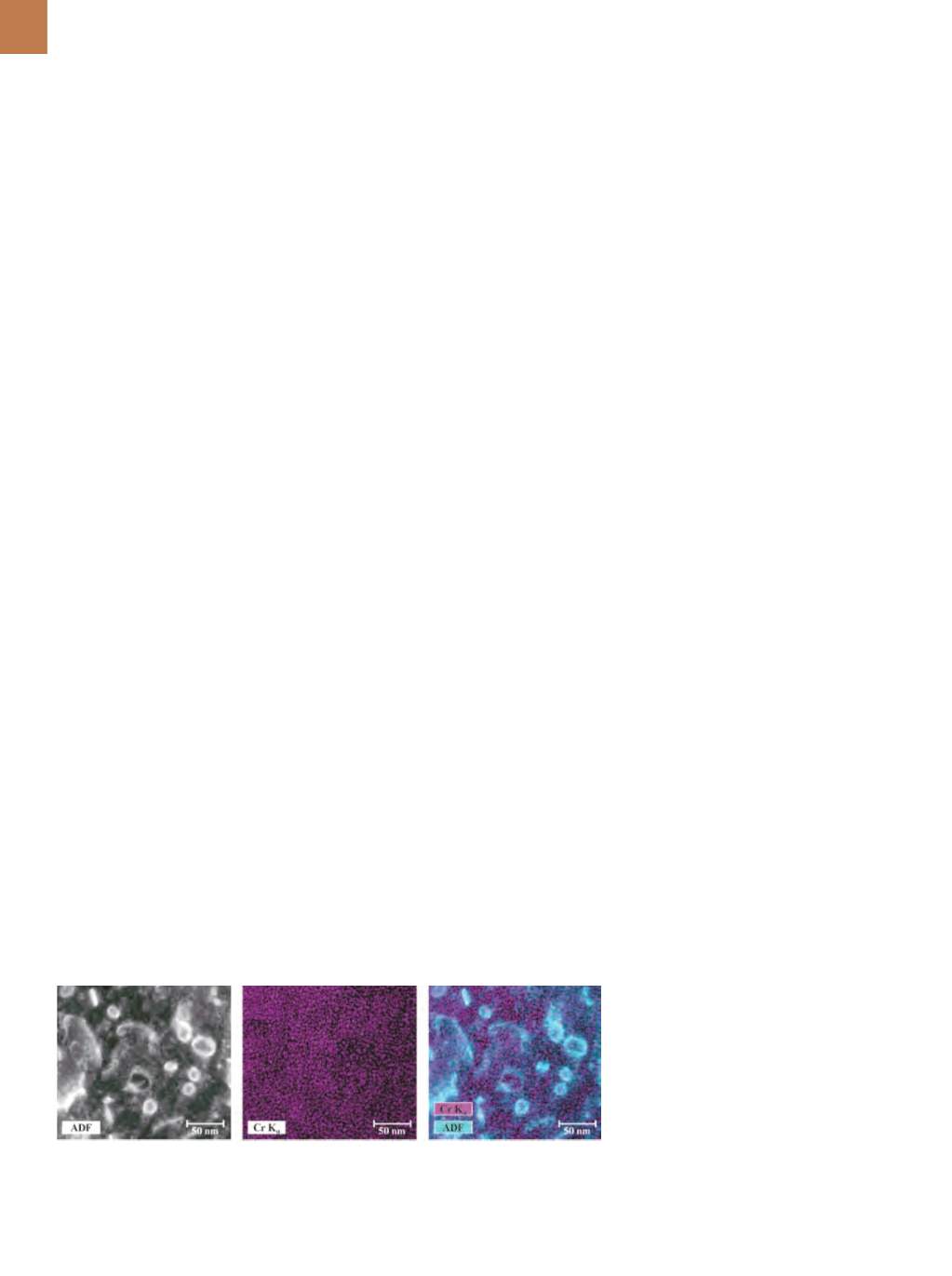

models used in the scattering analy-

sis. Artifacts of nuclear transmutation

resulting from neutron absorption are

observed in the generated time-of-flight

spectrum as manifested by peak ratios

that are inconsistent with expected

natural isotopic abundances of constit-

uent elements. In addition, peaks cor-

responding to transmutation products,

such as V and Mn, are also identified.

Due to the semi-coherency of

α

ʹ

particles in an

α

-ferrite matrix, conven-

tional diffraction contrast-based TEM

techniques are not useful for studying

the Cr-rich precipitates in this system,

necessitating the use of chemically

sensitive electron microscopy tech-

niques

[9]

. As such, energy dispersive

x-ray spectroscopy (EDS) was coupled

with STEM to acquire spectral images of

the precipitate microstructure. STEM/

EDS data collection was performed on

the FEI Talos F200X S/TEM located in

the LAMDA facility. Due to the high effi-

ciency of the FEI Talos system, care must

be taken when performing data analysis

as the energetic emissions of radioactive

decay from irradiated samples can be

easily detected along with the charac-

teristic x-rays, potentially muddling the

observed x-ray spectrum; this effect is

significantly reduced with FIB prepared

specimens over more traditional 3 mm

disc specimens. The x-ray maps were

collected concurrently with annular

dark field (ADF) images on the [111] zone

axis, allowing for simultaneous imaging

of dislocation loops

[10]

and collection

of EDS spectra in these materials. Fig-

ure 5 demonstrates that

α

ʹ precipitates

appear to nucleate homogenously in the

bulk material, with no bias for disloca-

tion loop or other defect sites.

THE FUTURE OF NUCLEAR

MATERIALS RESEARCH

Modern nuclear materials char-

acterization capabilities allow for an

in-depth, multifaceted investigation

of nanoscale precipitation events in

alloys, as demonstrated for

α

ʹ phase

precipitation in neutron-irradiated

Fe-Cr-Al alloys for accident-toler-

ant nuclear fuels applications. The

resulting detailed analysis of the

mechanisms and dependencies of pre-

cipitation in this system has informed

design decisions within the Fe-Cr-Al

alloy development program of the

DOE’s Advanced Fuels Campaign.

Generation II Fe-Cr-Al engineering

alloys with down-selected composi-

tions based on this work are currently

undergoing irradiation in HFIR to

study the effect of minor alloying ele-

ment additions on alloy radiation tol-

erance with the goal of recommending

a nuclear-grade Fe-Cr-Al LWR cladding

material in the near future.

Fe-Cr-Al alloys are just one of

many material systems currently being

developed for nuclear applications. For

example, SiC is being extensively inves-

tigated both as an alternative LWR clad-

ding material and for advanced TRISO

particle fuel for gas-cooled reactor tech-

nologies. Late-blooming phases (LBP)

that may embrittle reactor pressure

vessel (RPV) materials are also under

investigation in order to extend com-

mercial LWR operating licenses from

60 to 80 years. Additionally, improved

radiation tolerance of oxide-dispersion

strengthened (ODS) and nanostruc-

tured materials is being explored for

other in-core components.

Advancing nuclear materials tech-

nology and developing robust radi-

ation-tolerant alloys, ceramics, and

nuclear fuels is critical for both main-

taining and improving the existing com-

mercial LWR technologies in addition to

enabling the construction of next-gen-

eration reactor designs with even more

demanding environments for materials

performance. The modern characteri-

zation capabilities discussed here have

greatly facilitated high-quality charac-

terization research on nanoscale radia-

tion effects in materials. The continued

adoption of advanced characterization

techniques and equipment in addition

to ample access to this equipment by

nuclear materials researchers is antici-

pated to play a central role in enabling

informed materials development for

nuclear applications.

ACKNOWLEDGMENTS

Primary research funding was

sponsored by DOE’s Office of Nuclear

Energy, Advanced Fuels Campaign of

the Fuel Cycle R&D Program. Neutron

irradiation of Fe-Cr-Al alloys at ORNL’s

HFIR user facility was sponsored by the

Scientific User Facilities Division, Office

of Basic Energy Sciences, DOE. APT was

conducted at the CNMS, which is a DOE

Office of Science User Facility and the

MaCS Laboratory at the CAES at INL. A

portion of this work was supported by

the DOE Office of Nuclear Energy under

DOE Idaho Operations Office Contract

DE-AC07-051D14517 as part of a NSUF

experiment. The FEI Talos F200X TEM is

provided by the DOE, Office of Nuclear

Energy, Fuel Cycle R&D Program and

the NSUF. A portion of funding for SAB

was provided by the DOE Office of

Nuclear Energy’s Nuclear Energy Uni-

versity Programs.

The authors would like to thank

P.D. Edmondson and K.C. Littrell for

assistance in developing analysis tech-

niques used in this work. In addition,

they thank Y. Yamamoto for providing

the materials for irradiation and anal-

ysis, and R.H. Howard for leading irra-

diation capsule design efforts. Finally,

the authors acknowledge the staff of

the CAES, Irradiated Materials Examina-

tion and Testing (IMET) hot cell facility,

Fig. 5 —

(a) Colored STEM-ADF image, acquired on the [111] zone axis. (b) STEM/EDS map for

Cr-K

α

x-rays. (c) Color overlay of ADF image and EDS map. All images from the Fe-18Cr-2.9Al alloy

irradiated to 7.0 dpa at 320°C.

(a)

(b)

(c)