A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J A N U A R Y

2 0 1 6

2 7

oscillation—much like a crankshaft

and piston/rod assembly. A schematic

of the oscillator function is shown in

Fig. 1, in which the circle represents

the variable stroke crank.

Variable frequency is obtained

simply by changing the motor speed

that drives the crank. The phase change

of a second rotating cam that changes

the reference location of the driving

crank provides the variable amplitude.

Schematically, this increases or de-

creases the size of the circle in Fig. 1.

The oscillation method easily aligns

parts at the end of the welding cycle by

changing the variable amplitude at the

end of the cycle to zero. Application of

normal force and fixturing is similar to

other linear friction machine designs,

applying load perpendicular to the os-

cillating interface. A 100-ton mechani-

cal LFW system is shown in Fig. 2.

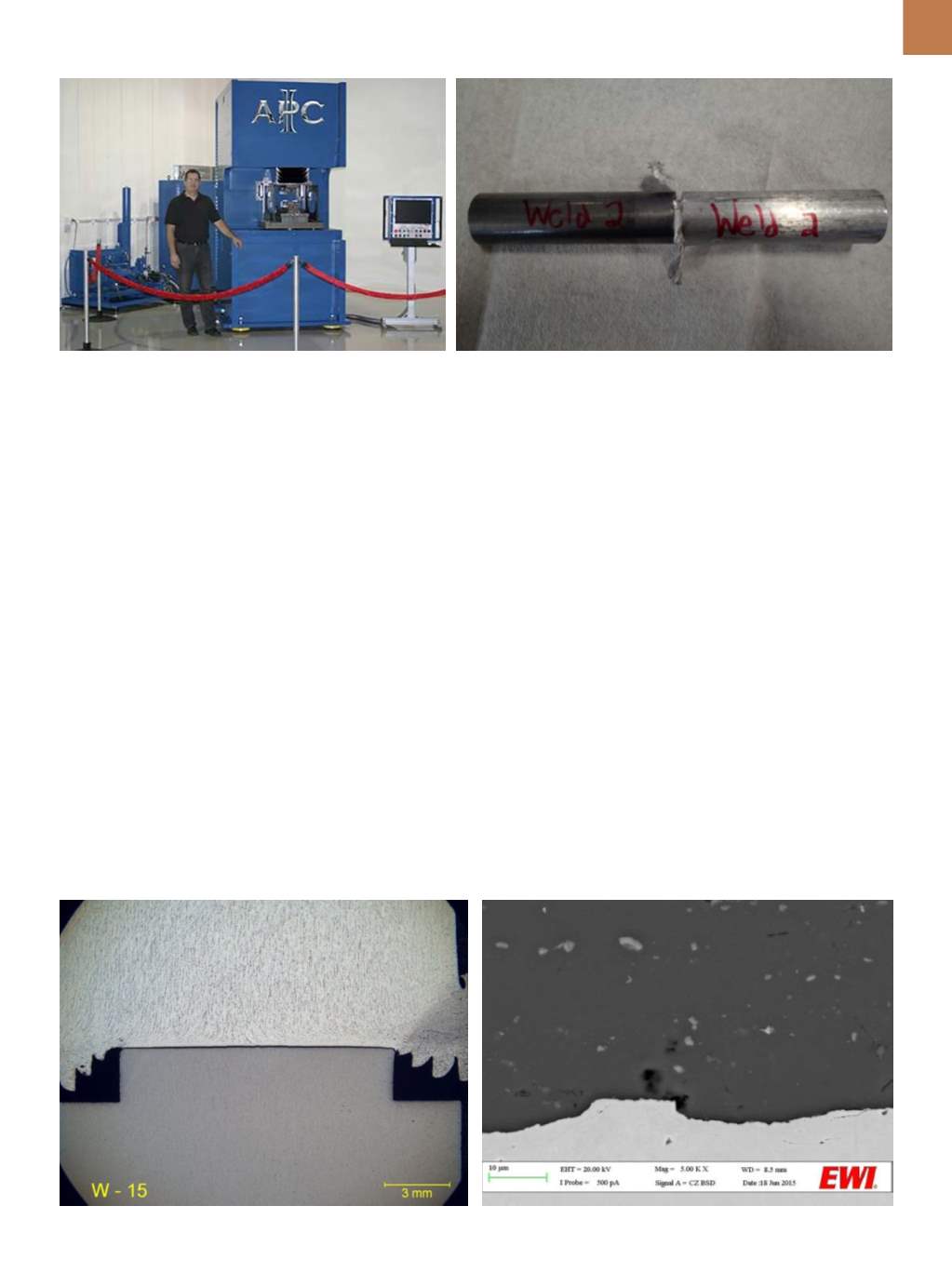

Fig. 2 —

100-ton mechanical LFW system. Courtesy of APCI.

Fig. 3 —

As-welded aluminum-to-steel joint.

Fig. 4 —

Cross-section of aluminum-to-steel joint.

Fig. 5 —

Aluminum-to-steel interface under high magnification using SEM.

This mechanical oscillation de-

sign greatly reduces machine cost and

footprint to approximately one-third

or less than the size of a comparable

hydraulic LFW system. The new system

also allows complexity to be added to

the weld process, including multiple

phases, extending low pressure fric-

tional pre-heats of the surface, and

changing the frequency and/or ampli-

tude in the middle of oscillation. Addi-

tionally, the mechanical system allows

for amplitudes exceeding 6 mm and

70 Hz of oscillation, thus expanding the

available parameters.

CASE STUDY

The automotive and aerospace

industries are both seeking weight re-

ductions via new materials with high

strength-to-weight ratios and multi-ma-

terial designs, commonly known as

lightweighting initiatives. Recent ad-

vancements in LFW technology enable

it to join aluminum alloys with over 90%

efficiency

[4]

. As an extension of this work,

EWI has examined joining aluminum to

steel with a mechanical LFW system.

Using this system, EWI joined 6061-

T6 aluminum to 1018 steel with joint

strengths matching that of the 6061-T6

base material. Joined pieces were 12.7

× 12.7-mm square faces with a 161-mm

2

cross-sectional area. Processing fre-

quency and amplitudes used to join the

pieces surpass traditional LFW capabili-

ty, resulting in joints exceeding 280 MPa

ultimate tensile strength. A photo of the

as-welded joint is shown in Fig. 3 and a

cross-section is shown in Fig. 4.

Joining dissimilar metals, includ-

ing this combination, typically results

in the formation of brittle interme-

tallic compounds with low strength,