A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J A N U A R Y

2 0 1 6

3 3

TABLE 1—TENSILE DATA SUMMARY FOR 0.014-IN. DIAMETER

SOLID-STATE WELDED GUIDEWIRES

Sample ID Sample

quantity

Break load

(Std. dev.), lb

% of

NiTi

break

load*

Failure location

LRM seamless joint

5

28.6 (0.72)

89

Joint interface

Hypotube joint

5

5.1 (0.35)

16

NiTi wire attached

to NiTi hypotube

*NiTi wire tensile strength for 0.014-in. NiTi wire was roughly 32 lb.

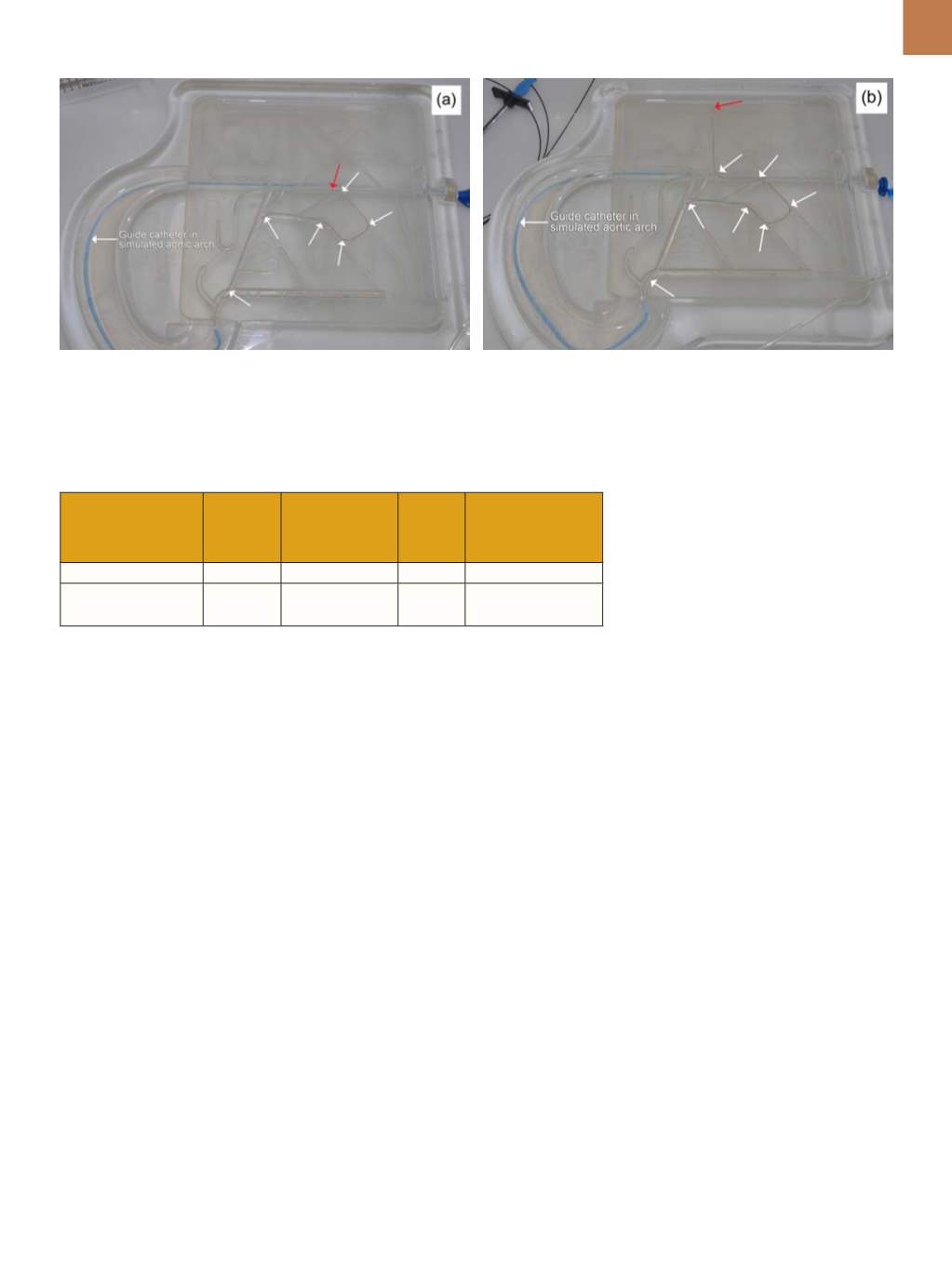

Fig. 6 —

Testing of LRM full guidewire 0.014-in. diameter in 2D plate model. Hypotube joint (a)

and LRM solid-state weld joint (b).

on the Nitinol wire, typical of a ductile

fracture mode, Fig. 5(d).

Figure 6 shows the two wires in

simulated performance testing using a

2D plate model, which features several

channels simulating tortuous vessels.

The wire is inserted through a guide

catheter (Vistabrite tip JL4 Fr manu-

factured by Cordis) into a predeter-

mined pathway to assess wire tracking

and torque response. The guidewire

with the LRM solid-state weld tracked

much further into the pathway than the

guidewire hypotube joint. Red arrows

indicate the distal-most position that

each wire navigated.

CONCLUSIONS

Nitinol wire was joined to stainless

steel wire via a proprietary solid-state

process without the use of filler materi-

al. This process proves to be a superior

method to create joints between dis-

similar metals such as stainless steel

and Nitinol. It offers significant perfor-

mance enhancements for guidewire

applications by merging a high-stiffness

stainless steel body for pushability with

a softer, more kink resistant Nitinol for

the distal section. The solid-state weld

process yields a fine-grained HAZ and

defect-free interface, resulting in excel-

lent bend and tensile properties at the

joint.

Initial performance testing using

a 2D plate model simulating vascula-

ture indicates that the LRM solid-state

weld offers superior performance in

clinical application compared to one

of the leading bimetal guidewires on

the market.

~AM&P

For more information:

Arne Rim-

mereide is manager of R&D, Lake Re-

gion Medical, 340 Lake Hazeltine Dr.,

Chaska, MN 55318, 952.641.8383,

arne. rimmereide@lakeregionmedical.com,

www.lakeregionmedical.com.

References

1. J. Pouquet, et al., Dissimilar Laser

Welding of NiTi to Stainless Steel,

Int. J.

Adv. Manuf. Technol.

, Vol 61, p 205-212,

2012.

2. P. Vondrous, L. Kolarik ,and M.

Kolarikova, Plasma Arc Welding of NiTi

and 304 Steel,

Annals of & Proceedings

of DAAAM Intl.

, Vol 23:1, p 2304-1382,

2012.

3. H.M. Li, et al., Laser Welding of TiNi

Shape Memory Alloy and Stainless

Steel Using Ni Interlayer,

Materials &

Design,

Vol 39, p 285-293, 2012.

4. S.D. Meshram, T. Mohandas, and G.M.

Reddy, Friction Welding of Dissimilar

Pure Metals,

J. Mat. Proc. Tech,

Vol 184,

p 330-337, 2007.

5. N. Kahraman, B. Gulenc, and F. Find-

ik, Joining of Titanium/Stainless Steel

by Explosive Welding and Effect on

Interface,

J. Mat. Processing Technol.,

Vol 169, p 127-133, 2005.

6. J. Tsujino, et al., Ultrasonic Butt

Welding of Aluminum, Aluminum Alloy

and Stainless Steel Plate Specimens,

Ultrasonics,

Vol 40, p 371-374, 2002.

7. A. Rajasekhar, Effect of Welding Pro-

cess and Post Weld Heat Treatments on

Microstructure and Mechanical Prop-

erties of AISI 431 Martensitic Stainless

Steel,

Int. J. Tech. Research and Appl.,

Vol 3, p 280-285, 2015.