A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J A N U A R Y

2 0 1 6

3 1

strength and joint quality evaluations

closer to the core central axis. The wire,

including the joint area, was ground to

diameters of 0.014, 0.010, and 0.008 in.,

then tensile tested to evaluate change

in joint strength throughout the cross-

sectional area. After initial joint strength

and quality assessments, full guidewires

were assembled using cores joined with

the LRM solid-state weld process from

0.014-in. stainless steel and 0.014-in.

Nitinol. The core wire distal grind pro-

file for this study mimicked the stiffness

profile of a commercially available bi-

metal guidewire, enabling performance

comparisons between the two designs.

The competing design wire consisted of

Nitinol and stainless steel joined via a

Nitinol hypotube and adhesive. The two

designs were tested side-by-side com-

paring lateral stiffness, tensile strength,

and simulated clinical performance in

a 2D plate model emulating a tortuous

vessel. After tensile testing, the fracture

surface was analyzed using a tabletop

SEM (Hitachi TM 300).

EXPERIMENTAL RESULTS

Results show that the new solid-

state welding process produces a clean

and defined transition between the

stainless steel and Nitinol and that the

interface is free of defects and/or po-

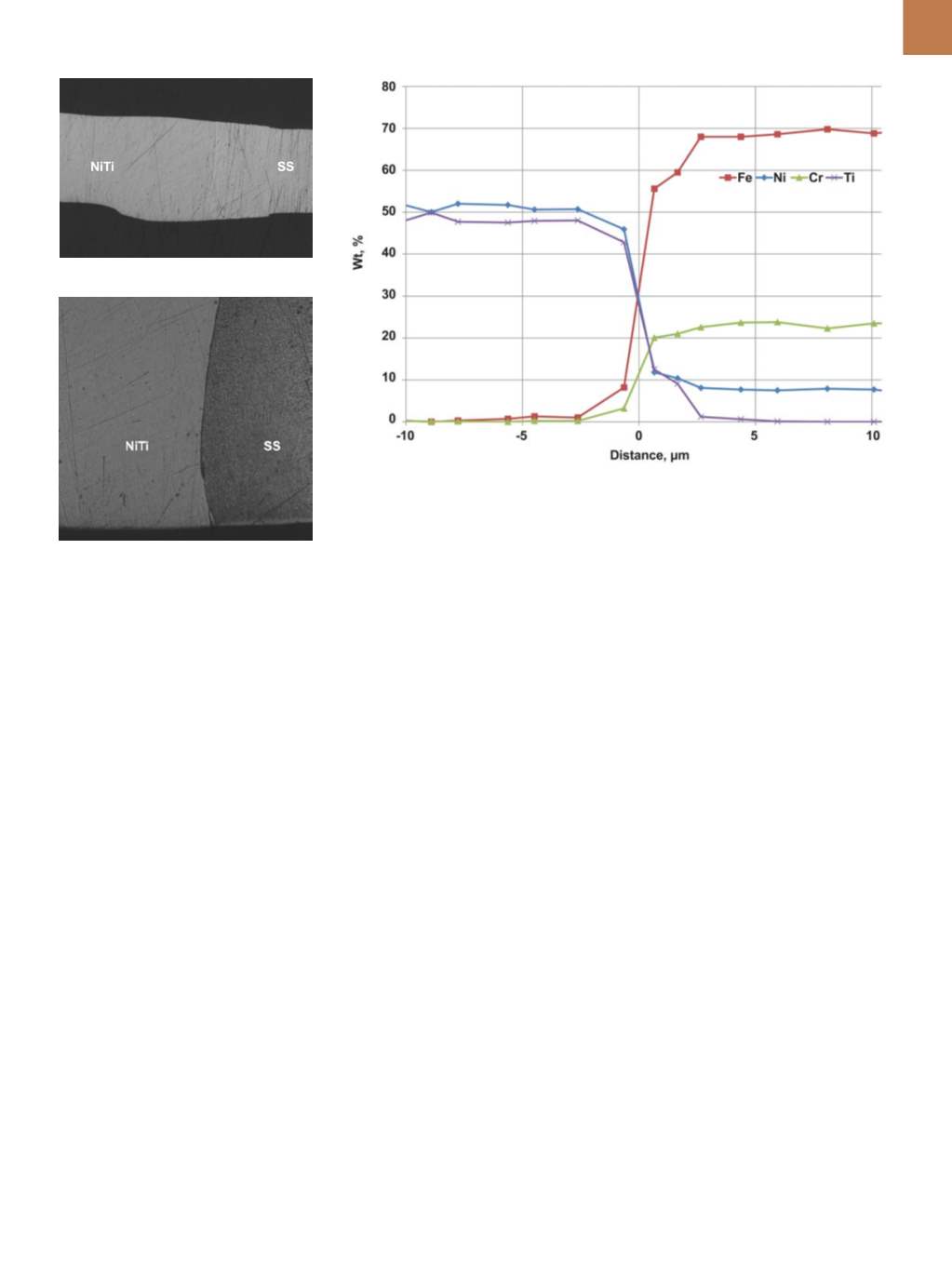

rosity. Figure 1 shows SEM images of a

joint cross-section between 0.018-in.

stainless steel and 0.020-in. Nitinol.

Figure 1(a) shows the interface after

polishing while Fig. 1(b) shows the in-

terface after etching the stainless steel

side. The heat-affected zone (HAZ) is

approximately 0.012-in. (~300 µm) long,

and is distinguished from the drawn

wire elongated grain structure by the

presence of a fine, uniform grain struc-

ture. A fine grain size is an inherent

solid-state processing advantage com-

pared to fusion welding, which is char-

acterized by the presence of a cast den-

dritic structure and large grains in the

HAZ

[2,7]

. Figure 2 shows the EDS analysis

at the interface of the solid-state weld

joint, collected within 10 µm on either

side of the joint. The data shows that

chemical intermixing of Nitinol and

stainless steel extends approximately

1 µmon either side of the joint interface.

LRM engineers ground welded

0.018-in. stainless steel and 0.020-in.

Nitinol wires to different diameters,

post joining in order to determine joint

grindability, thus providing design

options and an assessment of joint

strength uniformity toward the wire

central axis. All tested samples passed

the U-bend preconditioning test, which

indicates excellent joint bending prop-

erties. Tensile tests yielded an average

joint strength of approximately 80% of

the tensile strength of Nitinol wire. All

tensile samples failed at the stainless

steel to Nitinol interface, leading to

the hypothesis that a relatively small

HAZ and presence of fine grain struc-

ture contribute to the high strength of

the joint. With small sample sizes, 95%

of the confidence interval indicates no

loss of stiffness as the core diameter is

reduced via grinding as seen in Fig. 3.

Full guidewires were built using

the proprietary solid-state welded

joints located approximately 40 cm

from the distal tip. The grind profile

and joint location aligned with leading

competitive guidewires and enabled

comparative bench testing. Figure 4

shows the lateral stiffness results,

and the inset of Fig. 4 shows the LRM

solid-state weld joint in comparison

to the hypotube joint design. It is evi-

dent that the LRM joint is significantly

shorter than the 3-cm long hypotube

joint. The solid-state weld also shows

a smooth and even bending transition

from stainless steel to Nitinol, while the

Fig. 1 —

Post polishing SEM image of joint

shows its seamless nature (a); SEM image of

joint after etching shows presence of small

grains in HAZ (b).

(a)

(b)

Fig. 2 —

EDS composition profile at the interface for LRM solid-state weld joint.