A D V A N C E D M A T E R I A L S & P R O C E S S E S | J A N U A R Y 2 0 1 6

2 6

L

inear friction welding (LFW) is a

solid-state process that uses friction

and plastic deformation to gener-

ate heat. A metallurgical bond between

two pieces of material is achieved via

relative motion (i.e., friction) of mate-

rials under applied force. Solid-state

welding processes join without melting

materials and are in high demand due to

their superior weld quality, ability to join

non-fusion-weldablematerials, and over-

all lower peak temperatures than fusion

welding processes.

LFW is closely related to rotary fric-

tion welding, which uses relative angu-

lar motion under force to generate heat.

However, LFW uses

translational

motion

rather than

rotational

motion and is thus

able to join noncircular cross-sections as

well. Despite its advantages, industrial

applications of LFWhave been limited to

high value-added components such as

jet engine components due to prohibi-

tive equipment costs.

Recently, new advancements in os-

cillator technology have reduced equip-

ment costs and expanded LFW’s com-

mercial viability into applications ranging

from producing aluminum-to-steel joints

to the joining of railroad rails.

OSCILLATOR TECHNOLOGY

ADVANCEMENTS

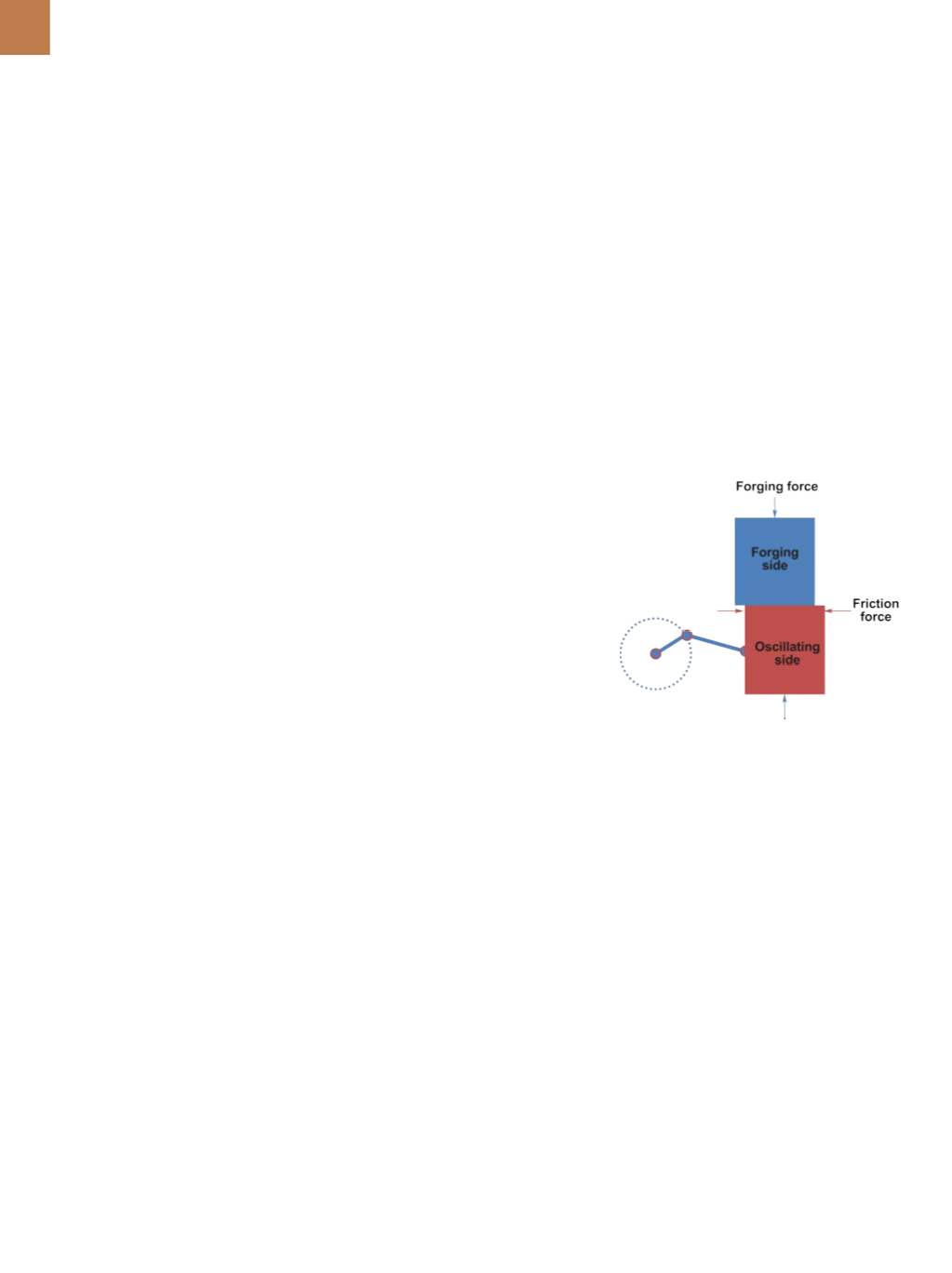

LFW achieves friction heating and

plastic deformation at the interface be-

tween the two components tobe joined.

As the material is heating, it is extruded

away from the joint and a new surface,

called a

nascent surface,

is formed. By

stopping oscillation and forging once

the nascent surface is formed, a weld is

made between the two pieces. A sche-

matic of this process is shown in Fig. 1.

Key variables for LFW include the

axial load along with oscillation fre-

quency, amplitude, and duration. LFW

machines must achieve the desired

relative velocities between two parts,

apply axial loads, and precisely stop

oscillation to align parts after weld-

ing. In order to maintain high relative

velocities under an axial load, shear

loads during welding can become

large. Therefore, designing an oscilla-

tor that can withstand the shear loads

opposing oscillation is one of the most

critical—and costly—factors of an LFW

machine.

Current LFW systems are most-

ly hydraulic actuation systems, which

store energy under high fluid pressure

that is first directed to one side of a

drive cylinder and then to the other

side to generate oscillation. High speed

valves with large flow rates, many paral-

lel circuits, and hydraulic accumulators

are required for hydraulic control and

must change flow direction in 1/60th

of a second to achieve a 60-Hz oscilla-

tion. Hydraulic servo valves operating

at speeds up to four times faster than

typical industrial servo valves provide

amplitude control

[1]

.

These machines require a signif-

icant investment in both capital and

floor space and are also complex to

operate and maintain. Due to their

size and complexity, hydraulic LFW

machines have been relegated to pro-

ducing only the highest value parts

for the most demanding applications.

A primary application for these sys-

tems is welding blades to disks for jet

engines

[2]

.

One

specialized

equipment

builder, APCI LLC, South Bend, Ind.,

recently developed a unique me-

chanically based oscillator for LFW.

Instead of the complex hydraulic sys-

tems used to oscillate a part, a motor

drive with a continuously variable

stroke crank

[3]

performs this task. Mo-

tor rotation drives the crank, which

translates rotary motion into linear

LINEAR FRICTIONWELDING

UPDATE: LOWERCOSTS,

BROADERAPPLICATIONS

From joining railroad rails to producing strong aluminum-to-steel

joints, recent advancements in linear friction welding are

reducing equipment costs and expanding potential uses.

Michael Eff, Jerry Gould, and Tim Stotler

EWI, Columbus, Ohio

Fig. 1 —

Mechanical LFW schematic.