A D V A N C E D M A T E R I A L S & P R O C E S S E S | J A N U A R Y 2 0 1 6

2 4

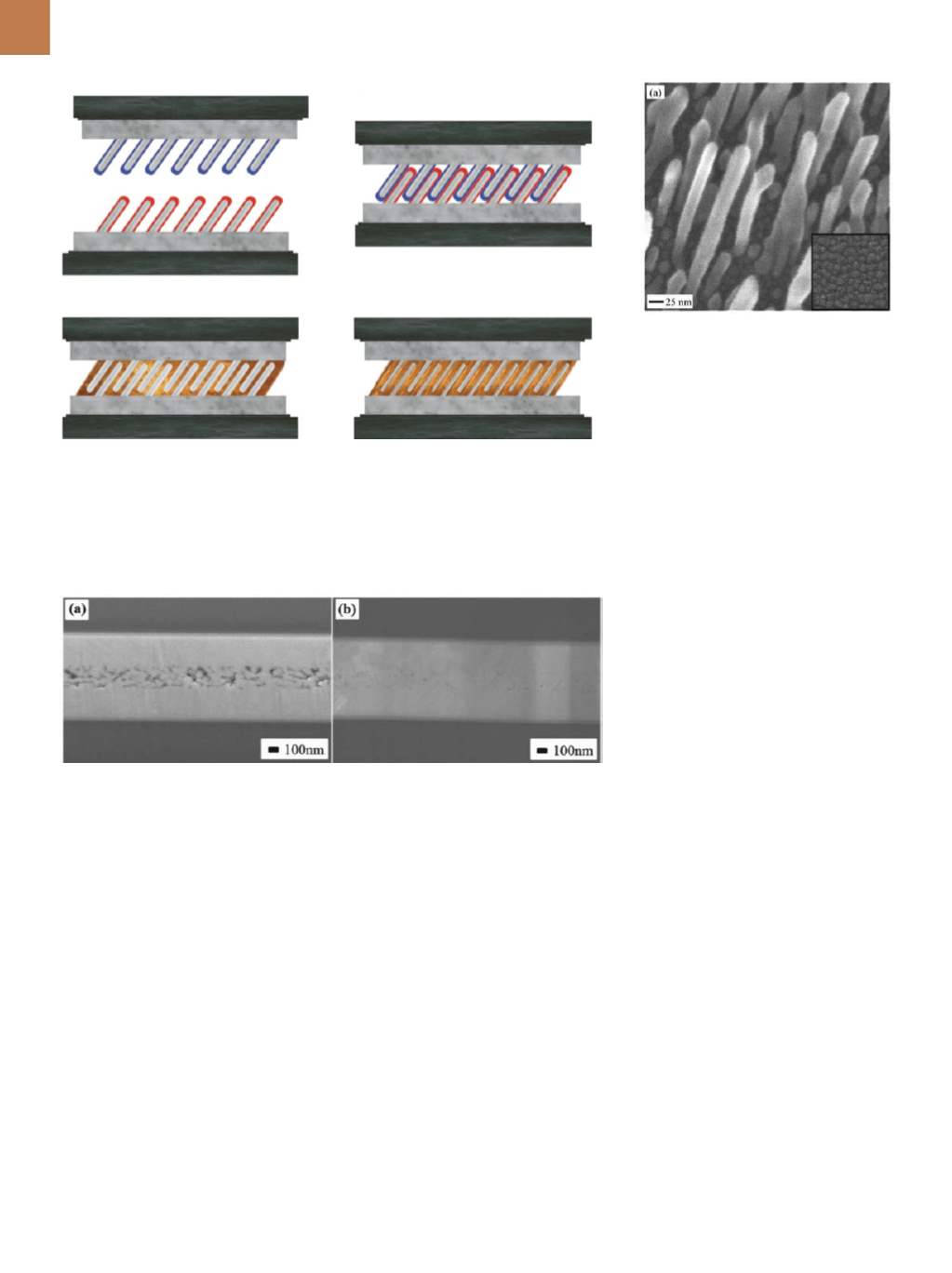

Fig. 2 —

Low-temperature metallic gluing enabled by well separatedmetallic nanorods:

(a) Two sets of well separated nanorods, which have metallic cores and shell elements that

form a eutectic alloy, are brought together, (b) they interpenetrate under fingertip pressure,

(c) shell elements meet and form a eutectic alloy, which is liquid at room temperature, and

(d) mixing of eutectic liquid with a metallic core leads to formation of three-component

alloys that are solid at room temperature.

Fig. 3 —

Scanning electron microscope

image of well separated Cu nanorods. Cour-

tesy of X. Niu, et al.,

Phys. Rev. Lett.,

Vol 110,

136102, 2013.

Fig. 4 —

Metallic glue formed in air and under a small pressure of 9 MPa (a) at room tempera-

ture, and (b) at 100°C. Reprinted with permission from

Scientific Reports

[15]

.

so diffusion on the nanorod surface is

much faster than on flat surfaces

[16]

.

Contact of the sides of the nanorods

through interpenetration provides high

surface area contact, maximizing the ef-

fects of the fast surface diffusion.

While the use of eutectic materials

as shells shows preliminary results of

a room temperature bond at very low

pressure, it is possible to use simpler,

single element nanorods in place of the

core-shell structure required in the eu-

tectic. Silver was successfully used to

create such a bond, but requires higher

pressure for sealing

[15]

.

TECHNOLOGICAL IMPACTS

The impact on technology is clear,

even using only well separated silver

metallic nanorods without a shell. Fol-

lowing the processes in Figs. 2a and 2b,

the fast surface diffusion of nanorods

without the liquid formation of eutec-

tic alloys, gluing also occurs, although

with some voids (Fig. 4a)

[15]

. To reduce

void concentration, a higher process-

ing temperature is needed. As shown in

Fig. 4b, performing the gluing process

at 100°C largely eliminates voids. Using

core-shell nanorods, and therefore the

assistance of liquid from the eutectic

alloy, it is expected that the room tem-

perature gluing process will produce a

bond that is void free, as seen in Fig. 4b.

Even with voids, the metallic glue

shown in Fig. 4a has superior ther-

mal conductivity and leak resistance.

In tests running a simulated CPU at

moderate load with forced air cool-

ing, the metallic glue reduces the CPU

temperature by 8°C ±3°C compared to

the widely used thermal grease, Arctic

Silver 5, operating at 61°C. This is signif-

icant, as keeping the CPU 10°-15°C cool-

er can double its lifespan

[5]

. The leak

rate of the metallic glue shown in Fig. 4a

is three orders of magnitude lower than

that of polymeric glue. This leak resis-

tance meets the standard for organic

solar cell and organic light emitting

diode technologies

[15]

, allowing them

to survive long-term, which may lead

to a new generation of inexpensive so-

lar and lighting technology. Further, as

demonstrated in Fig. 1d, metallic glues

are also useful as a vacuum seal. Capi-

talizing on the superior leak resistance

of the metallic glue, MPF Manufacturing

is investigating using the technology

and licensing the patent

[17]

.

Looking forward, the core-shell na-

norod glue is expected to perform even

better. First, the use of eutectic alloys

through the core-shell nanorods will re-

duce or completely eliminate the voids.

As a result, leak resistance will further

increase, and heat conduction will be-

come even more effective. Second,

the presence of liquid alloys instead of

solids will likely reduce the processing

pressure from a few megapascals to a

fraction of one megapascal, equivalent

to fingertip pressure.

~AM&P

Formore information:

HanchenHuang

is professor and chair, department

(a)

(b)

(c)

(d)