A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J A N U A R Y

2 0 1 6

2 1

it may be beneficial to perform these

comparisons before making additively

manufactured structural parts.

In addition, tensile specimens

could have been manufactured to near-

net size to reduce specimen preparation

time and cost. The

z

orientation (vertical)

specimens could have been manufac-

tured to net size, allowing for a compar-

ison between as-manufactured surfaces

and smooth machined surfaces. This

comparison may be important for parts

with significant fatigue loading.

Fatigue curves were not generat-

ed. Instead, parts were subjected to a vi-

bration acceptance test, which showed

that the parts would be sufficient for

the specific mission, but did not lead

to a standard stress-versus-cycles (S-N)

curve that could be used for other parts

and applications. Vibration acceptance

and/or fatigue curve generation should

be considered if fatigue loading is a con-

cern in other applications.

Testing of three non-HIP’d tensile

specimens suggests that HIPing may not

be necessary to achieve desired strength

levels. ASTMF3055 requires the sameme-

chanical properties for Class D (stress re-

lieved, HIP’d, solution treated, and aged)

and Class F (same as Class D, except no

HIPing) parts. Results described here

support this, but there were not enough

specimens to make a complete compari-

son on the effect of HIPing.

Finally, now that industry standard

ASTM F3055 is available for use, it may

be easier to standardize manufacturing

processes from different vendors. All of

the parts in this application were made

consecutively by one vendor, but this

may not be possible in a large produc-

tion environment.

~AM&P

For more information:

Andrew Clifton

is an associate manager in Structur-

al Materials and Processes, Lockheed

Martin Space Systems Co., 1111 Lock-

heed Martin Way, Sunnyvale, CA 94089,

408.742.1502,

andrew.c.clifton@lmco. com, www.lockheedmartin.com.

References

1. J.J. Schirra, R.H. Caless, and R.W.

Hatala, The Effect of Laves Phase on

the Mechanical Properties of Wrought

and Cast + HIP Inconel 718,

1991

Superalloys Conference Proceedings,

tms.org/superalloys/10.7449/1991/ Superalloys_1991_375_388.pdf.2. G.F. Vander Voort, G.M. Lucas, and

E.P. Manilova, Metallography and Mi-

crostructures of Heat-Resistant Alloys,

in

ASM Handbook,

Volume 9:

Metallog-

raphy and Microstructures,

p 837, ISBN

0-87170-706-3.

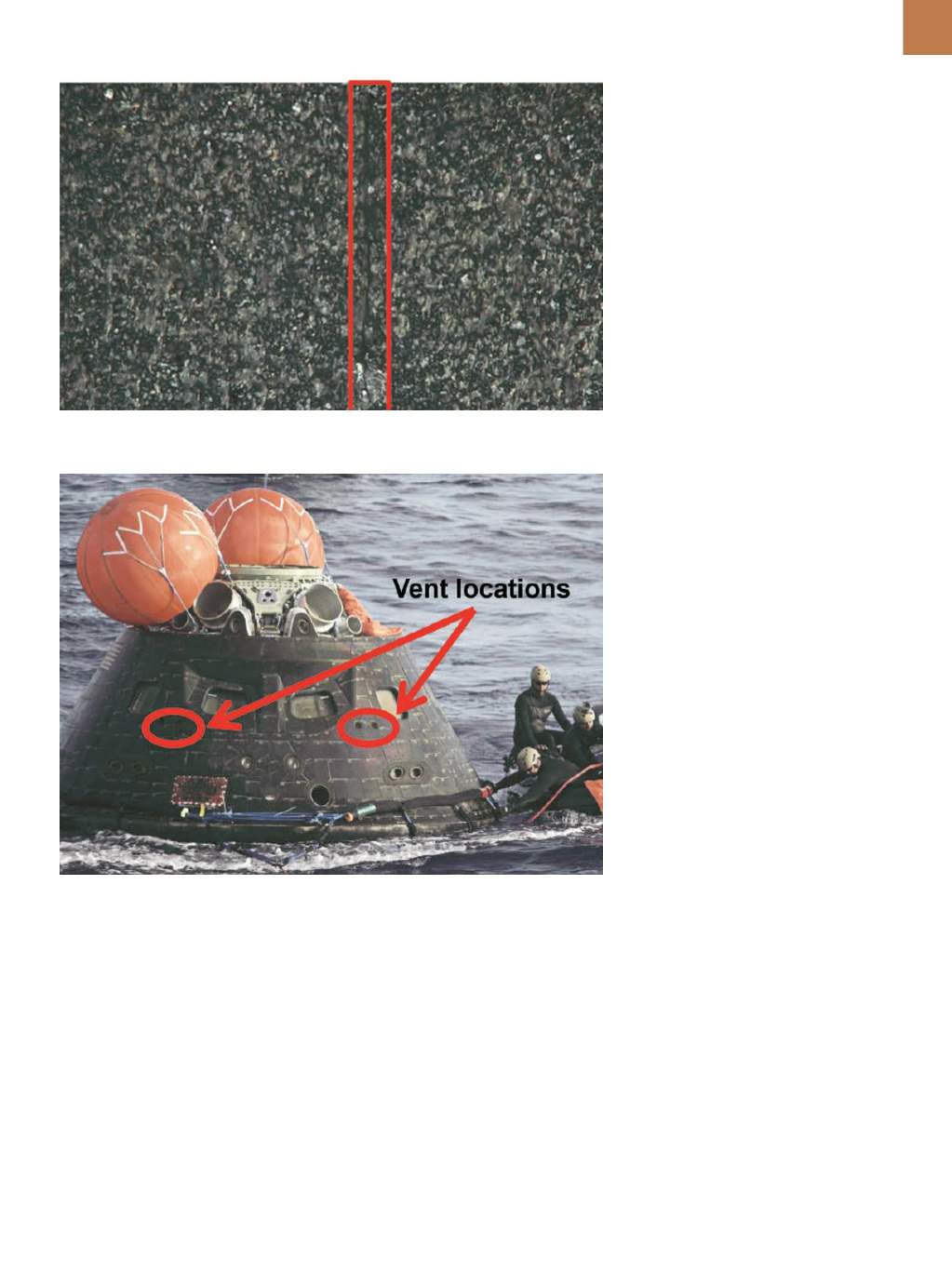

Fig. 8 —

Orion Exploration Flight Test 1 vehicle in the Pacific Ocean after landing. Courtesy of

NASA.

Fig. 7 —

Build pause on vertical tensile specimen. Build direction is left to right.