A D V A N C E D M A T E R I A L S & P R O C E S S E S | J A N U A R Y 2 0 1 6

3 2

hypotube joint design exhibits sharp

transitions that could cause kinks and

performance degradation.

The lateral stiffness graph shows

the seamless nature of the LRM guide-

wire at around 40 cm from the distal tip.

A direct change in stiffness occurs at the

solid-state weld joint. Conversely, the

graph shows that the sample guidewire

with the 3-cm long hypotube joint has a

less desirable stiffness load profile.

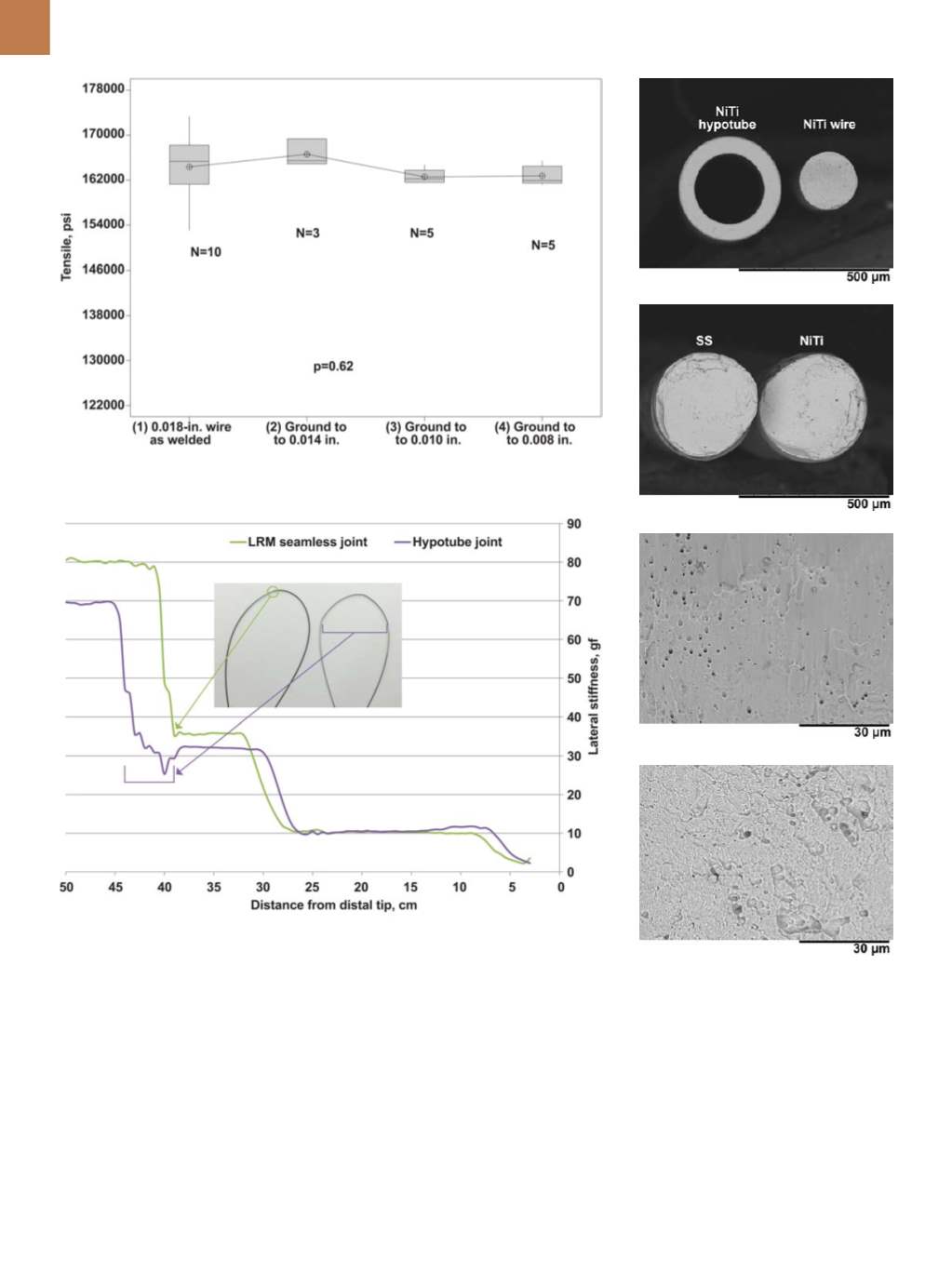

Fig. 3 —

No statistically significant difference, at a 95% confidence level, in joint tensile strength

with reduction in cross-sectional area. This shows joint consistency.

Fig. 4 —

Lateral stiffness testing on 0.014-in. diameter guidewire with LRM solid-state joint,

compared to competitive guidewire with hypotube joint.

Fig. 5 —

SEM image of fracture surface, post

tensile testing. Lowmagnification (200×) of

hypotube joint and LRM solid-state joint,

respectively (a) and (b); high magnification

image (2000×) of NiTi wire side of hypotube

joint and LRM solid-state joint, respectively

(c) and (d).

Table 1 summarizes the tensile

data for 0.014-in. diameter LRM solid-

state welded guidewires. The LRM joint

exhibits high tensile strength compared

to the hypotube adhesive joint. Figures

5(a) and 5(c) show that the failure mode

for the hypotube joint design was ad-

hesive failure, with subsequent core

pullout from the hypotube. Therefore,

the Nitinol wire end exhibits a smooth

shear cut surface, Fig. 5(c). The LRM

solid-state weld joint failed at or near

the joint interface, Fig. 5(b). The frac-

ture surface of the LRM solid-state weld

exhibits micro-roughness and dimples

(a)

(b)

(c)

(d)