A D V A N C E D M A T E R I A L S & P R O C E S S E S | J A N U A R Y 2 0 1 6

3 6

METALLURGY LANE

Metallurgy Lane, authored by ASM life member Charles R. Simcoe, is a continuing series dedicated to the early history of the U.S.

metals and materials industries along with key milestones and developments.

PIONEERS IN METALS RESEARCH—PART IV

EDGAR BAIN PIONEERED THE STUDY OF THE REACTION OF AUSTENITE TO LOWER TEMPERATURE PHASES

DURING ISOTHERMAL TRANSFORMATION, RESULTING IN A NEW PHASE NAMED IN HIS HONOR

—

BAINITE.

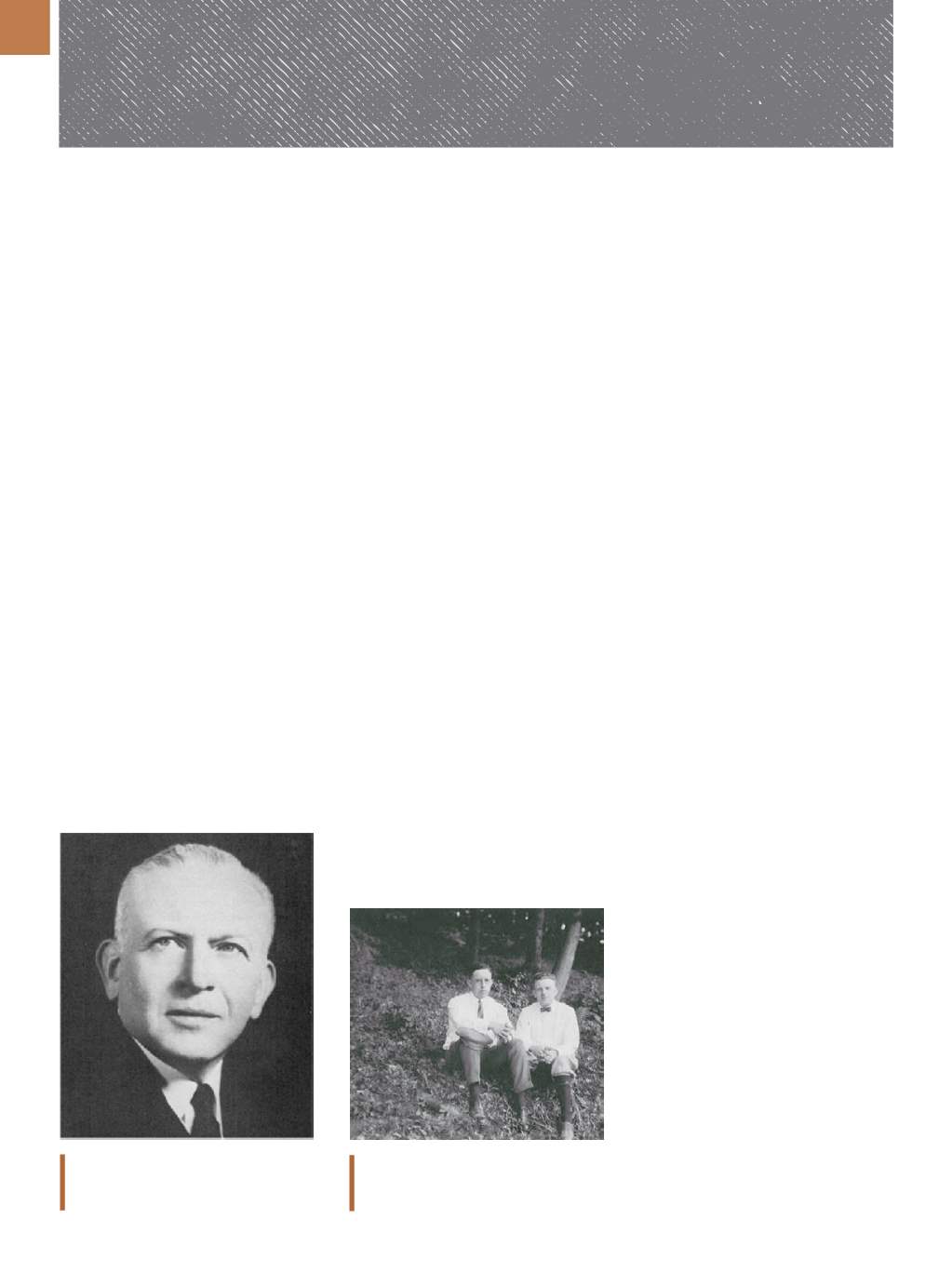

American metallurgist Edgar C. Bain, of

bainite fame. Courtesy of Library of

Congress.

A

fter finishing high school in Mar-

ion, Ohio, Edgar C. Bain enrolled

at The Ohio State University in

chemical engineering in 1908. His initial

interest inmetallography began in a class

where he saw photomicrographs of fer-

rite, pearlite, and martensite. Bain would

follow this field of science throughout his

career. His first job after graduation was

with the National Bureau of Standards in

Washington. Aftera fewyears, he returned

to Ohio State to work on an advanced

degree, where he took the only course

offered in metallography and metallurgy.

Before he earned his master’s degree, his

department head recommended him as

an instructor at the University of Wiscon-

sin teaching metallography and pyrome-

try. Due to his limited knowledge, he first

took a summer course in these subjects.

He selected the laboratory course at

Columbia University taught by William

Campbell and Henry Marion Howe.

He taught at Wisconsin for one

year, then accepted a research posi-

tion at the B.F. Goodrich Co. When the

U.S. entered WWI, Bain joined the army

where he worked in chemical warfare

research. After his discharge, he joined

General Electric’s National Lamp Works

where he worked under Zay Jeffries.

His first assignment was to investi-

gate the problem of failed dies of high-

speed steel during the wire drawing of

tungsten. He studied the mechanism of

secondary hardening, which was still a

mystery after 20 years of use. Bain and

Jeffries published their results in a fa-

mous paper on the “Red Hardness of

High-Speed Steel” in

Iron Age

magazine

in 1923. They combined the principles

of precipitation hardening by Paul Dyer

Merica with a mechanism of slip for

rows of atoms to slide past one another

for plastic deformation. The secondary

hardening they proposed was that the

formation of tungsten carbide at 1100°F

keyed the slip to increase the hardness.

Bain also studied the crystal struc-

ture of metal solid solutions using x-ray

diffraction, a new tool. Previous theory

taught by Howe at Columbia and Al-

bert Sauveur at Harvard stated there

were patches of crystal structure of the

solvent and other patches with the sol-

ute. Bain’s results for copper and zinc

(brass) showed for the first time that

the solute atoms of a different crystal

structure simply replaced solvent at-

oms at random without changing the

crystal structure.

After four years of working with

Jeffries at GE, Bain joined Atlas Steel in

Dunkirk, N.Y., where he worked on high-

speed and other alloy tool steels with

Marcus Grossmann. This was an espe-

cially productive time for Bain as he was

now pursuing a career studying transfor-

mation during steel heat treatment and

the effect of alloy additions. Alloy steels

were becoming ever more important

with the expanded production of auto-

mobiles and farm machinery, but un-

derstanding heat treatment and alloying

elements had made little progress.

In July 1924, Bain joined the Union

Carbide and Carbon Corp., a producer

of ferroalloys including ferrochromium.

During the summer of 1927, he took a

leave from his work and visited steel

plants, laboratories, and universities

in Europe with Grossmann. They met

with some early researchers who had

done the first studies on tool steels,

alloy steels, and the transformation of

austenite.

From left to right, Marcus Grossmann and

Edgar Bain of Atlas Steel Corp., Dunkirk,

N.Y., circa 1923. Courtesy of ASM.