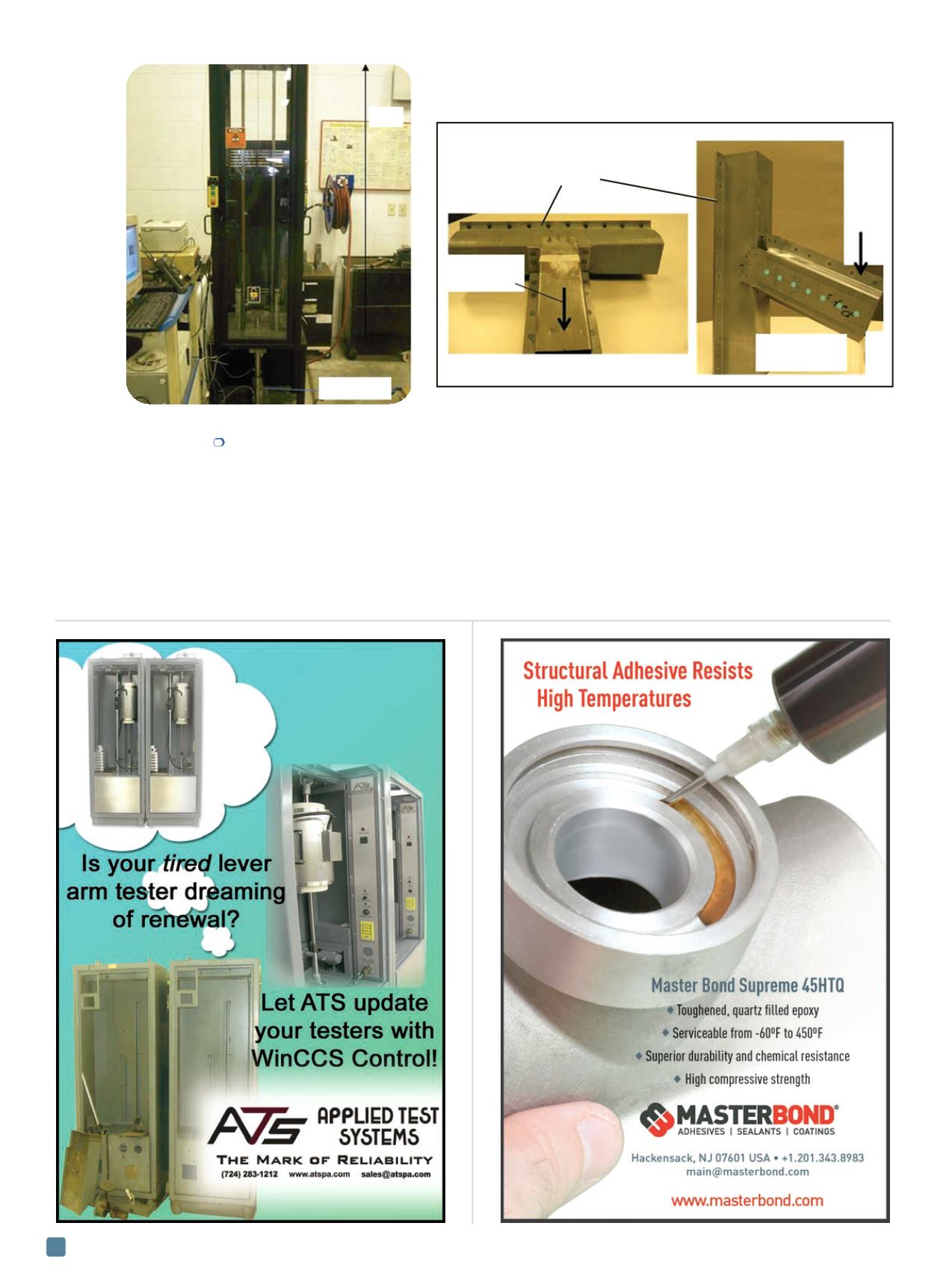

Fig. 9

—

Broken T-Section samples.

ADVANCED MATERIALS & PROCESSES •

NOVEMBER-DECEMBER 2014

22

signed and tested to validate failure parameters at the com-

ponent level.

For more information:

Yu-Ping Yang is a principal engineer

in the structure integrity and modeling group at EWI, 1250

Arthur E. Adams Dr., Columbus, OH 43221, 614.688.5253,

yyang@ewi.org,

ewi.org.

References

1. S.-H. Lin, et al., A General Failure Criterion for Spot Welds

Under Combined Loading Conditions,

Int. J. Solids Struct.,

Vol

40, p 5539-5564, 2003.

2. F. Seeger, et al., An Investigation on Spot Weld Modeling

for Crash Simulation with LS-DYNA, 4th LS-DYNA User

Forum, Bamberg, Germany, 2005.

3. Y.P. Yang, et al., Integrated Computational Model to Predict

Mechanical Behavior of Spot Weld

, Sci. Technol. Weld. Join.,

Vol 13(3), p 232-239, 2008.

4. Y.P. Yang, et al., Development of Spot Weld Failure Param-

eters for Full Vehicle Crash Modeling,

Sci. Technol. Weld. Join.

,

Vol 18(3), p 222-231, 2013.

5. N. Mori, et al., Fatigue Life Prediction Methods for Spot

Welds in T-Shaped Members Under Bending, SAE Paper

860604, Warrendale, PA, 1986.

Fig. 8

—

Drop tower for

high speed sample

testing.

8 .5 ft

Sample

Cover plate

Transverse

load

Longitudinal

load