most prominent among these is enhanc-

ing test efficiency. As metals producers

demand greater throughput, they seek an

increased return on assets and look to in-

strumentation suppliers for solutions that

will assist them in accomplishing more

with their testing systems.

“testXpert II was designed to maxi-

mize testing efficiency, to save time in the

setup process. For example, the test envi-

ronment is stored, so the user simply en-

gages the tools that are to be used and the

software automatically recalls the load

cell, grips or platens, movement direction,

extensometer, hard limits, soft limits, and

the test space,” says Goblirsch.

With more than 500 test programs

available, the software enables test per-

formance in compliance with over 900

standards. In addition, automatic unit

conversion ensures that the software

speaks the customer’s language—units

correspond with industry standards. The

software also features standard test pro-

grams, which pre-store protocols in ac-

cordance with specific standards. For labs

that run a wide range of standards, a mas-

ter test program is available to support a

host of standards for tensile, compression,

flexure, tear, cyclic, melt flow, pendulum

impact, and hardness tests.

The software can also perform com-

pliance testing on its own routines. A spe-

cialized function called

Tenstand

verification

can validate the procedure in

the software to demonstrate that the soft-

ware itself is meeting test requirements.

Learning new testing routines takes time

and requires a learning curve to achieve a

high level of competency. Incorporating a

consistent user interface allows standard-

ization of training and testing routines

from system to system around the world.

Support for regulatory compliance

As regulatory bodies continue to

focus on elevating safety and traceability,

testing and verification processes that

occur as part of product development and

quality assurance routines are emerging

as documentation centers. Measurement

and control software for materials testing

systems helps support the establishment

of audit trails and process controls. These

factors are particularly important in the

medical industry, where regulation has

undergone substantial change in the past

decade. Meeting stringent requirements

associated with FDA and EMA (European

Medicines Agency) regulations repre-

sents a significant and ongoing challenge

for participants in the medical products

industry.

Recordkeeping requirements are de-

scribed under FDA 21 CFR Part 11. This

mandate requires pharmaceutical and

medical device manufacturers, biotech

companies, and other FDA-regulated in-

dustries to implement controls, including

audits, system validations, audit trails,

electronic signatures, and documentation

for software and systems involved in pro-

cessing electronic data required to be

maintained by FDA predicate rules, or

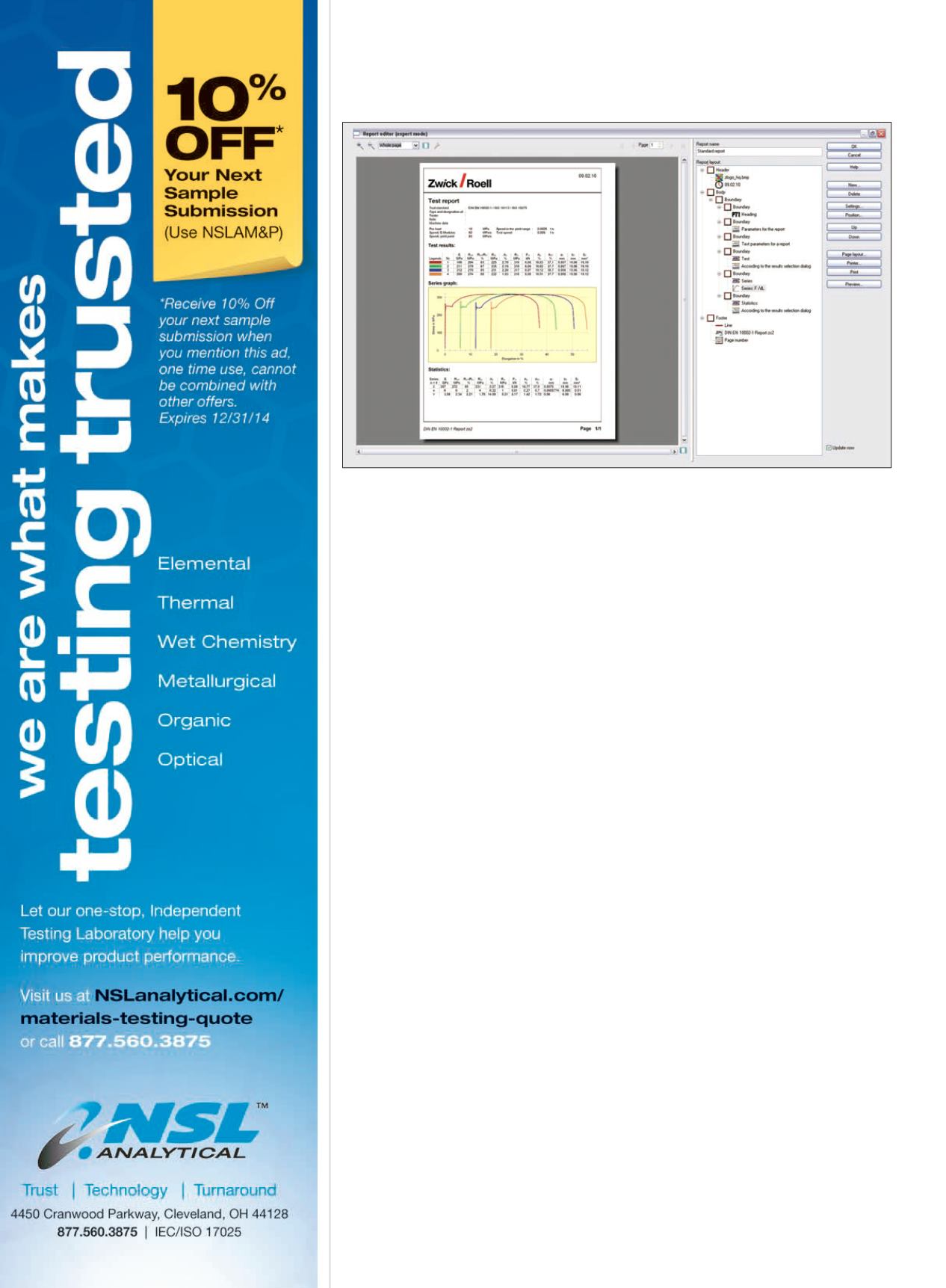

A report generation function facilitates data export and organizes key information into a

simplified format.