ADVANCED MATERIALS & PROCESSES •

NOVEMBER-DECEMBER 2014

23

T

he emergence of novel alloys and high strength

steels in support of automotive lightweighting ini-

tiatives is changing manufacturing processes as well

as supply chain centers. Metals producers, seeking advan-

tage in an increasingly competitive global market, are em-

phasizing differentiation. Physical properties and

mechanical properties, in particular, play a major role in

product performance. These factors, in combination with

challenging new applications, are creating new require-

ments for materials testing.

“Production of novel alloys, aluminum, and emerging

grades of steel is scaling up to address high visibility engi-

neering challenges such as global demand for lighter pas-

senger vehicles. Alcoa, Novelis, and ArcelorMittal are

leading market growth in these sectors and we are begin-

ning to see new complexities for materials testing emerge,”

says Manfred Goblirsch, software development manager

for Zwick/Roell, a manufacturer of materials testing equip-

ment based in Ulm, Germany. “Thorough materials char-

acterization is required for both product development and

quality assurance. We recognize, however, that for end

users to achieve their growth objectives, testing must not

impact productivity.”

While responding to evolving market conditions,

manufacturers must also prepare for an increase of engi-

neering professionals approaching retirement. Over the

next decade, engineering and technical fields are ex-

pected to see a talent shortage, stimulating the need for

recruitment and training programs as well as employee

retention efforts. Testing labs are charged with address-

ing the convergence of these issues while maintaining

productivity and delivering accurate measurement results

to internal customers.

Software solutions

Software specifically designed for materials testing en-

vironments and quality control laboratories offers a solu-

tion to many of these challenges. Measurement and control

software governs every action undertaken by testing sys-

tems and—working together with the electronics—delivers

the required functionality. All software elements, from the

architecture and its capacity to support complex algo-

rithms demanded by some of the most challenging appli-

cations, to flexibility such as accepting external channels

and handling data export to proprietary applications, help

support test procedures in labs. As standardized testing

protocols and methods across global facilities are sought,

testing equipment must maximize the potential to syn-

chronize the entire testing process to reduce errors and en-

hance consistency.

“As an example, our corporate software licensing pro-

gram enables a company with global test sites to centralize

testing protocols and subsequently dispatch them to vari-

ous sites within the company network. Our customers

have also indicated that this functionality is particularly

helpful in coordinating round robin tests. With a corpo-

rate software license, a central lab can also specify the ap-

pearance of the user interface and scale this out globally,”

explains Goblirsch.

The Zwick testXpert II software includes built-in tuto-

rials in order to simplify training. Organized to mentor

new operators as well as experienced technicians seeking

tips on operational efficiency, the tutorials shorten training

time, allowing users to begin testing shortly after setup. In

addition, user management capabilities suggest privilege

restrictions and allowances at various levels in order to

support lab supervisors managing complex workflows.

While responding to changing needs at the user level

has spurred simplification of the user interface, other fac-

tors have influenced the software design as well. Perhaps

TECHNICAL SPOTLIGHT

Dedicated Software

Maximizes

Efficiency in Materials Testing

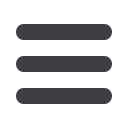

Drag and drop simplicity within the graphical sequence editor function of

testXpert II software supports rapid changeover times between tests and

helps reduce measurement errors.

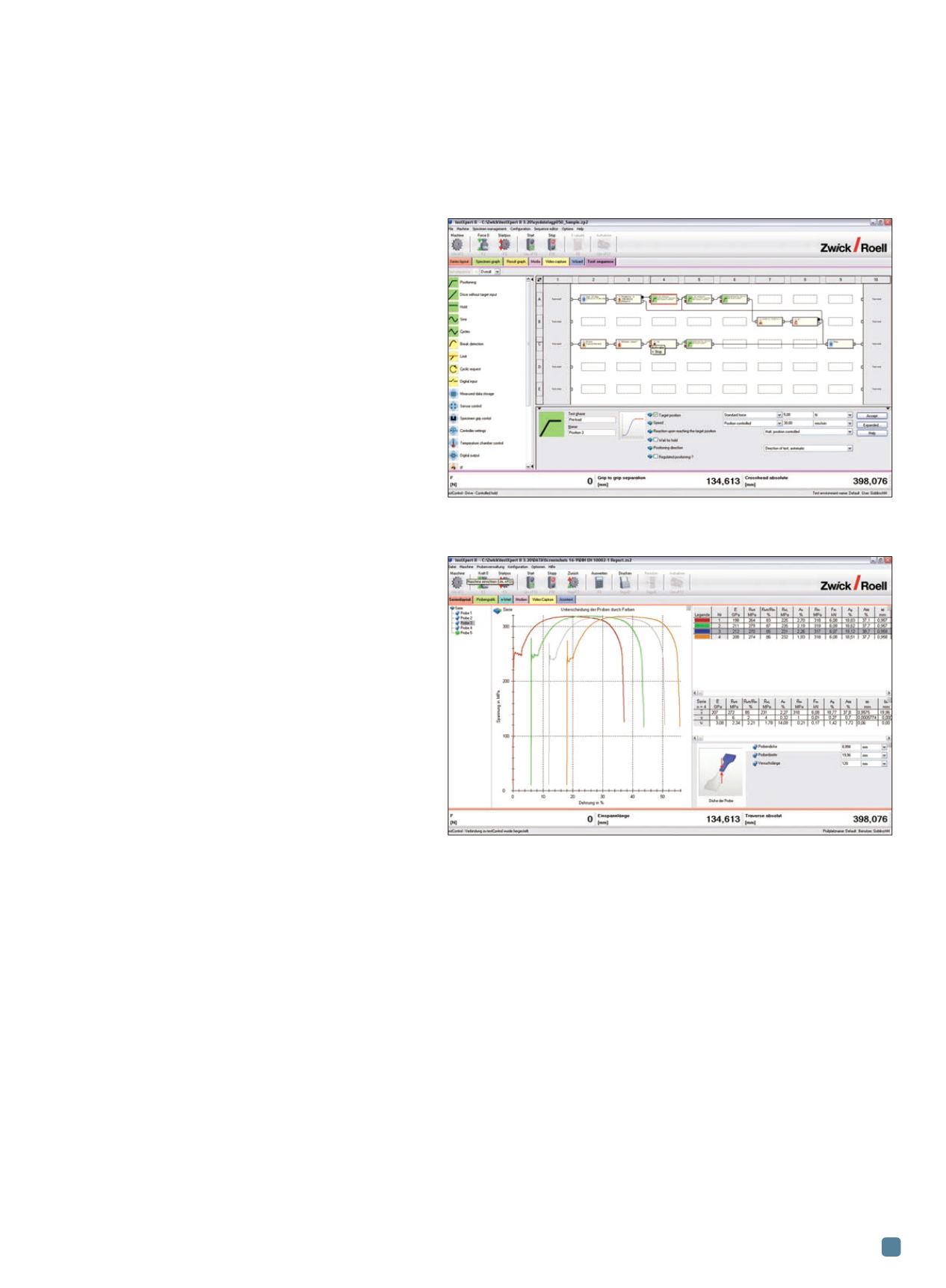

Software enables rapid comparison of results for analysis and reporting

purposes.