ADVANCED MATERIALS & PROCESSES •

NOVEMBER-DECEMBER 2014

26

M

icrosecond (ms) fiber lasers have been success-

fully used in medical device applications such as

hypo tube and stent cutting for years. While pre-

cise and fast, parts require a number of post processing op-

erations after they are cut, which can damage mechanically

delicate parts and add cost. A new ultra-short femtosec-

ond (fs) laser technology produces pulses that do not leave

a thermal fingerprint on parts. These disk-based femtosec-

ond lasers offer sub-400 fs pulses, high beam quality, and

peak power that enable a high quality cold ablation cutting

process rather than a melt ejection process. Resulting cuts

require minimal post processing and the small beam size

allows machining of very fine details.

The process works well for production of medical de-

vices such as catheters, heart valves, and stents, for med-

ical and glass cutting and marking applications, and

3D-structuring of ceramic material for dental implants.

Perhaps the most interesting potential use involves an en-

tirely new class of bioabsorbable materials—polymers that

safely remain in the body for a certain time before absorb-

ing. They are being developed as an alternative to tradi-

tional polymers or metal parts.

In the past, fs lasers were considered too slow for com-

mercially viable operations. However, recent studies eval-

uated cutting time per part and post processing steps, and

demonstrate a return on investment for a disk femtosec-

ond laser in less than 12 months (in many cases), especially

for high value components. A key aspect of realizing the fs

laser’s potential is the system platform. Two companies

working to address this issue include Jenoptik and Miyachi

America, who are jointly developing both stage and scan

head platforms to achieve new levels of quality and preci-

sion for micro treatment.

Femtosecond laser basics

Femtosecond (fs) light pulses are ultra-short pulses

(USPs). One fs equals 10

-15

seconds and as a calibration

point, a 300 fs pulse equates to a physical pulse length of

only 90 µm. Because there is no thermal processing as

there would be in nanosecond (ns) pulses, USPs offer cer-

tain advantages, including:

• Unchanged material characteristics without

thermal tension

• No shock waves or structural changes

• Smooth processed surfaces without microcracks

• Elimination of melting effects and structural changes

• Surface damage is eliminated and rework or post

processing is not required

• Cleaning is unnecessary and there is no debris

• Clean surfaces due to lack of ejected material

• Smooth edges because there is no recast layer

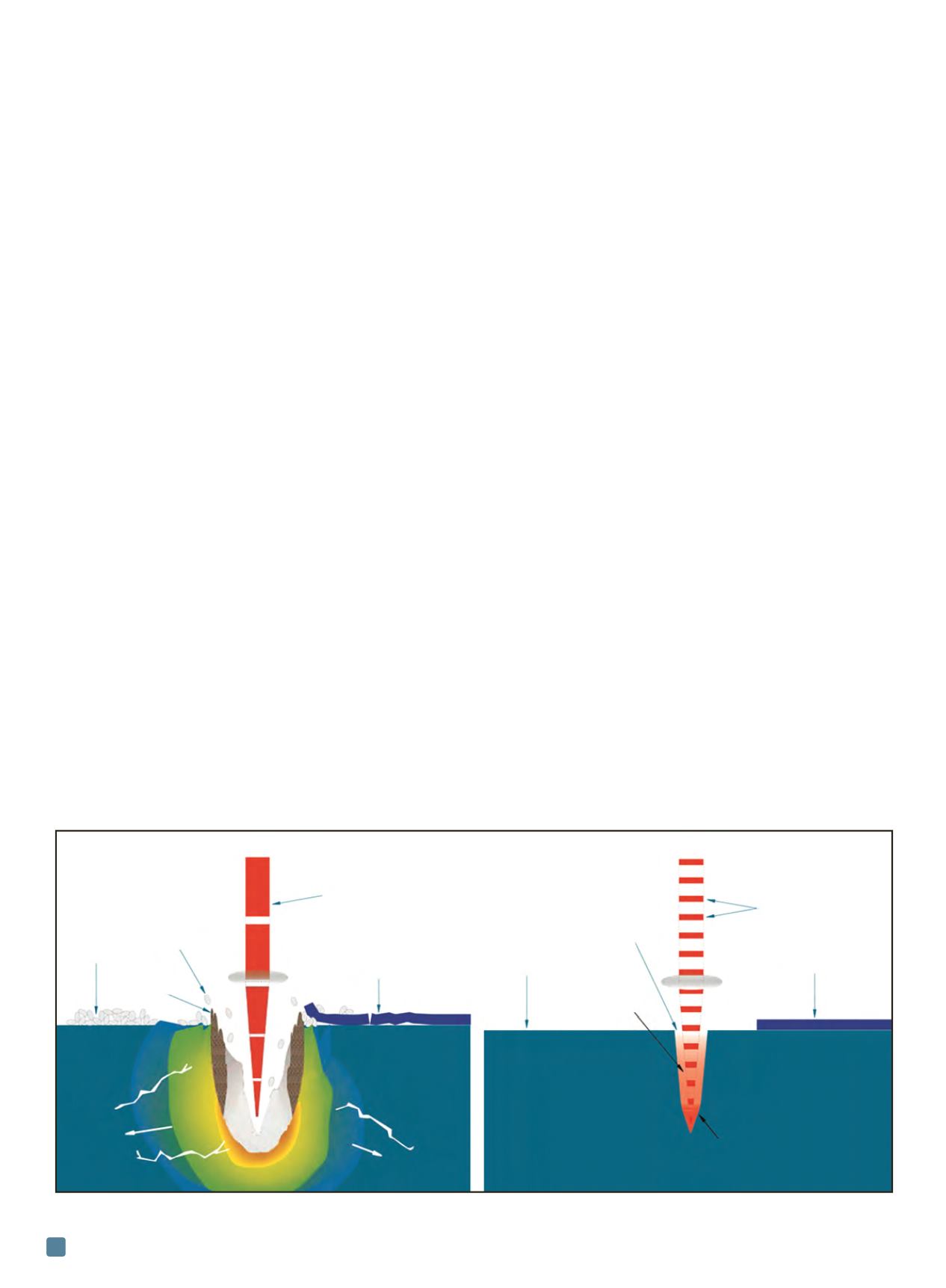

Figure 1 shows these effects on an application using a

long pulse laser (for example, µs) compared to that of an

ultra-short pulse laser like an fs laser.

Femtosecond laser technology is not new—it has been

widely used in institutions and research centers for more

than 30 years, but commercial fs technology that can en-

dure an industrial environment with 24/7 qualification was

only developed within the last decade. Originally used for

wafer dicing and scribing of P1, P2, and P3 solar panels or

Femtosecond Laser Processing

Overcomes Barriers for Use

in Medical Device Manufacturing

TECHNICAL SPOTLIGHT

Fig. 1 —

Schematic processing comparison of microsecond to femtosecond lasers.

Long pulse

laser beam Ultra-short

laser pulses

Ejected material No recast layer

Surface debris

Damaged surface No debris No damaged surface

Recast layer

Plasma plume

Heat affected zone No microcracking No heat transfer

Microcracking

to surrounding material

No melt zone

Melt zone

Shock waving No shock waving Hot, dense ion/electron soup

Heat transfer to (i.e., plasma)

surrounding material

Application with long pulse laser (µs)

Application with ultra-short pulse laser (fs)