ADVANCED MATERIALS & PROCESSES •

JANUARY 2014

21

Development of Hardfacing Alloys

for Power Generation Applications

M

any issues exist concerning the spec-

ification, manufacturing, and use of

high-performance valves in the fossil

and nuclear power generation industries. In-

creased unit flexibility (cyclic operation),

higher-temperature operation (for higher effi-

ciency), and radiation exposure (nuclear power)

are key drivers for new opportunities in the de-

velopment of materials and manufacturing

processes for valve components. A recent arti-

cle in

AM&P

discussed the promise of powder

metallurgy and hot isostatic pressing (PM/HIP)

technology for ferritic and stainless steel com-

ponents production. This technology addresses

a wide range of issues regarding cast valve com-

ponents, including inspection, performance,

and supply chain pinch points such as procure-

ment, machining, and rework or refurbish-

ment, including weld repair

[1]

.

Ongoing research and development at the

Electric Power Research Institute (EPRI), de-

tailed in this article, examines the application

of wear-resistant hardfacing materials using the

PM/HIP process. The hope is to eliminate

weldability and residual stress challenges asso-

ciated with some of the hardfacing alloys, as

well as provide a wider range of potential alloy

solutions for two key concerns, detailed here.

Table 1 provides chemical compositions of the

materials discussed in this article.

A drive to eliminate cobalt from hardfaced

components such as valve seats, discs, and

stems remains in the nuclear power industry.

Hardfaced component wear during operation

may result in transporting Co to the reactor

where it is transformed into highly radioactive

Co

60

. This isotope has a half-life of more than

five years and is a major culprit in occupational

radiation exposure to plant personnel working

on valve components or near potential crud

trap sites during outages.

Delamination (also referred to as liberation

or disbonding) of hardfacing material from fer-

ritic valve seat and disc substrates results in col-

lateral damage to the steam turbine and valve

operational function(s) (i.e., failure). An exam-

ple of delamination hardfacing in a Grade 22

valve disc is shown in Fig. 1. This problem has

John Siefert*

David Gandy, FASM

Dan Purdy

John Shingledecker*

Electric Power

Research Institute,

Charlotte, N.C.

Ryan Smith

Tapasvi Lolla

The Ohio State

University, Columbus

Suresh Babu, FASM*

The University of

Tennessee, Knoxville

Lou Lherbier, FASM*

David Novotnak*

Carpenter Technology

Corp.

Reading, Pa.

Development of wear-resistant hardfacing materials using powder

metallurgy/hot isostatic pressing technology offers an alternative to today’s

cobalt-based materials and those that suffer delamination damage.

*Member of ASM International

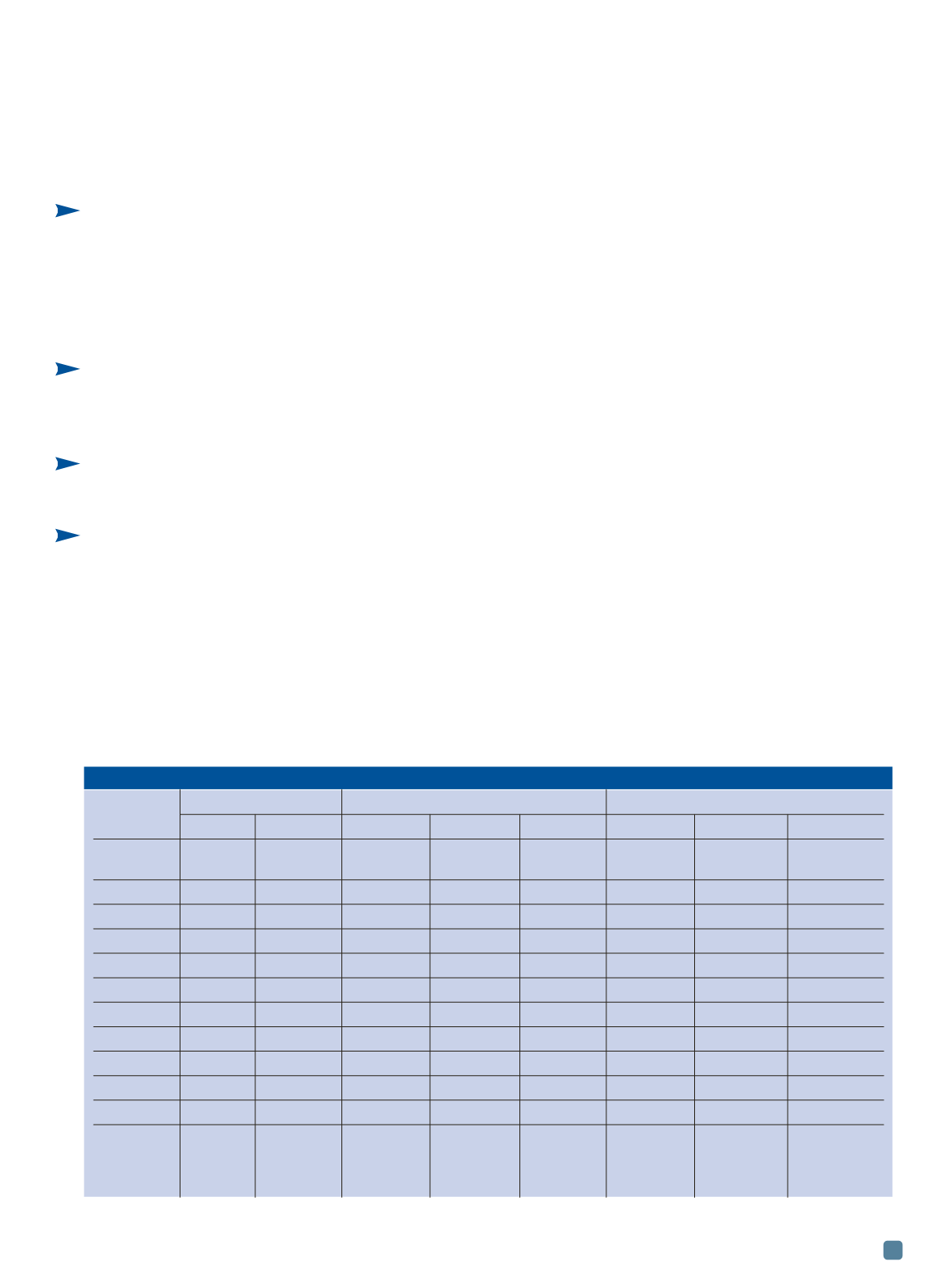

TABLE 1 — MATERIAL CHEMICAL COMPOSITION

Hardfacing

Potential Butter Layers

Substrate Materials

Element

Alloy 6

Alloy 21 FM625

ER309

316L Grade 22 Grade 91

Industry

Nuclear

Nuclear

Fossil

Fossil

Fossil

Nuclear

Fossil

Fossil

and Fossil Candidate

C

0.9-1.4

2.5

0.20-0.35 0.10 max 0.04-0.12 0.030 max 0.05-0.15 0.07-0.14

Ni

— — 2.0-3.0 58.0 min

12-14

10-14

— 0.40 max

Cr

27-32

25

26-29

20-23

23-24

16-18

1.9-2.6

8.0-9.5

Fe

— Bal.

— 1.0 max

Bal.

Bal.

Bal.

Bal.

Mo

— 3.2

4.5-6.0 8.0-10.0 0.3 max

2-3

0.87-1.13 0.85-1.05

Mn

— ≤1.0

— 0.50 max

1.0-2.5

2 max

0.30-0.60

0.30-0.60

Si

— ≤0.5

— 0.50 max

0.30-0.65

1 max

0.5 max

0.20-0.50

P

— — — 0.02 max

0.030 max 0.045 max 0.025 max

0.020 max

S

— — — 0.015 max 0.020 max 0.030 max 0.025 max

0.010 max

Co

Bal.

— Bal.

Bal.*

— — —

—

Others

W: 4.0-6.0 V: 0.5

— Nb: 3.15-4.15 — N: 0.10 max

— Nb: 0.06-0.10

Al: 0.40 max

V: 0.18-0.25

Ti: 0.40 max

Al: 0.020 max

Ti: 0.010 max

*Ni+Co