many fission products. FHR is intended for operation at

700°C or higher

[10]

. This concept originates back to research

performed at Oak Ridge National Laboratory during 1950-

70

[11]

. Under the program known as molten salt reactor ex-

periment (MSRE), a 7.5 MW molten salt reactor with

uranium fuel dissolved in a molten fluoride salt was built and

operated at 650°C. The present FHR concept uses solid

TRISO fuel particles immersed in the molten salt medium,

but many of the corrosion challenges will be similar to those

experienced in MSRE. Fluoride salt FLiBe (2LiF-BeF

2

) is

being considered as a primary coolant for FHR.

Corrosion of structural materials in molten fluoride

salt is an important issue in FHR

[12]

. In most high temper-

ature environments, corrosion resistance is achieved by

promoting the formation of a protective oxide film on the

alloy surface. However, in molten fluoride salt systems, any

such protective oxide films dissolve by the fluxing action of

the salt and cannot be used for corrosion protection. Once

the passive oxide film is removed, corrosion proceeds by

the attack of the least noble constituent of the freshly ex-

posed alloy surface. Thermodynamically, the salt fluorides

are more stable than metal fluorides, indicating that most

structural alloys should be stable in molten fluoride salts.

Ni is relatively immune to corrosion in molten fluoride

salts. Studies show that impurities such as moisture can

dramatically accelerate corrosion due to the formation of

hydrogen fluoride

[13]

. Examples of impurity reactions are

listed below. In the case of FLiBe, for example, water could

react with Be- and Li- fluorides in the salt and produce HF

gas, which in turn could leach the Cr in the alloy into the

salt as fluorides. Impurities such as Ni or Fe in the salt can

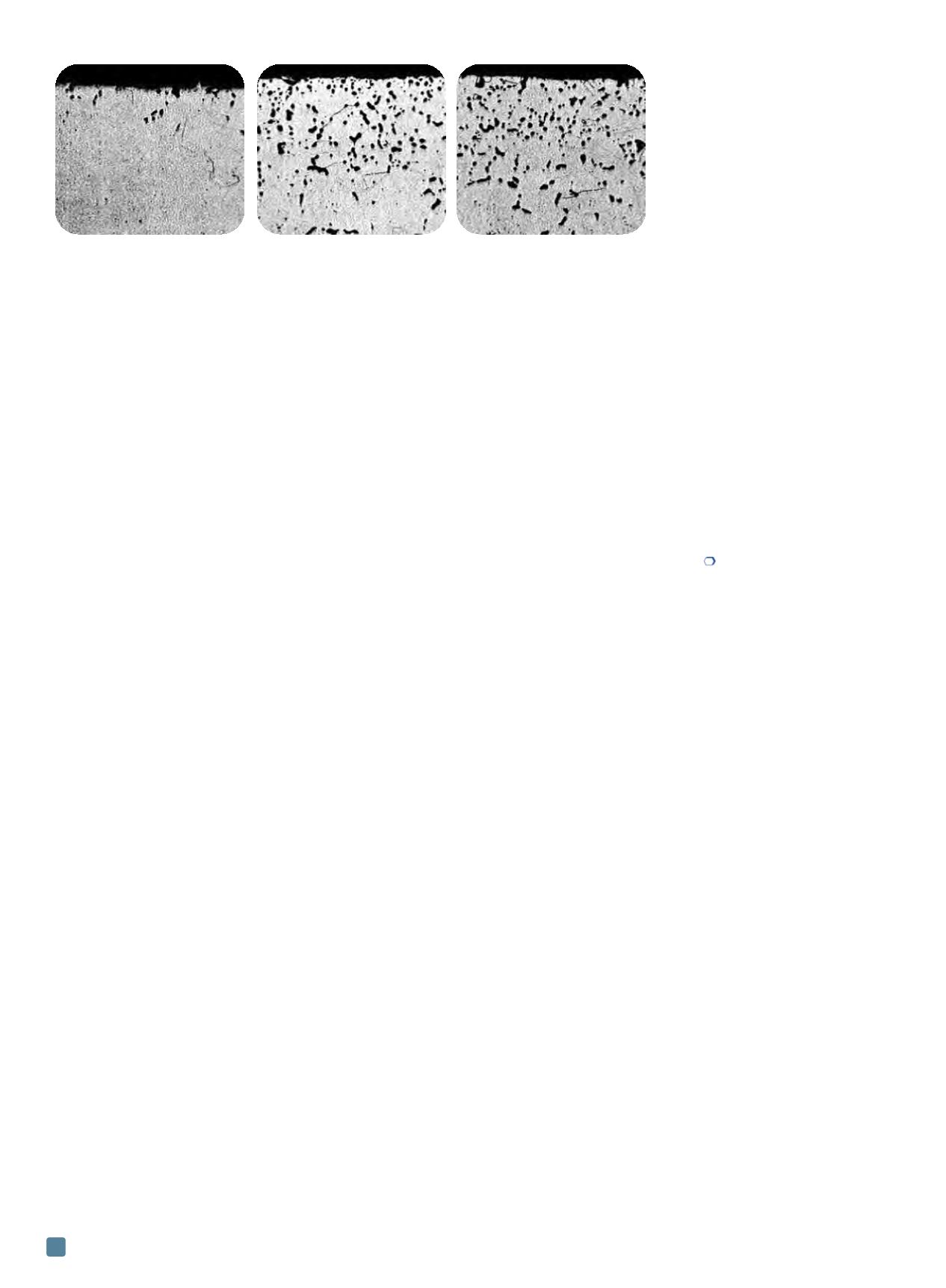

also promote dissolution of Cr into the salt. Figure 5 illus-

trates the effect of impurities in the molten fluoride salt on

corrosion from MSRE research.

BeF

2

+ H

2

O = BeO + 2HF

2LiF + H

2

O = Li

2

O + 2HF

2HF + Cr = CrF

2

+ H

2

NiF

2

+ Cr = CrF

2

+ Ni

Other types of corrosion in molten salts include dissimilar

material corrosion where deterioration is driven by ele-

mental activity differences between various materials in

the molten salt. For example, corrosion of stainless steel

tested in a molten fluoride salt in graphite crucibles is sig-

nificantly greater than in stainless steel crucibles

[12]

. Ther-

mal gradients can also drive corrosion due to the strong

dependence of solubility on temperature. Corrosion prod-

ucts that dissolve at the higher tem-

perature sections of the system can

partially plate-out in the relatively

cooler sections of the system. Cor-

rosion control in molten salts be-

gins with using high purity salts

with extensive purification treat-

ments. For FLiBe and other fluo-

ride salts, sparging with H

2

/HF is

effective for purification. Controlling the salt’s redox po-

tential by adding elements such as beryllium is also effec-

tive in mitigating corrosion

[11]

.

Hastelloy N—a relatively low Cr content alloy with

Mo—was developed by the MSRE program exclusively

for molten fluoride salt applications

[11, 13]

. This alloy must

be code-certified for use at the higher temperatures re-

quired for FHR. Currently, 316L stainless steel with ac-

tive redox control is being considered for FHR

applications. FHR will also involve other materials such as

graphite and SiC/SiC composites. Corrosion testing and

evaluation of all these materials in molten FLiBe salt at

the intended high temperatures of FHR is required and

being conducted as a part of the FHR development pro-

gram in the U.S. and China.

For more information:

Kumar Sridharan is Distinguished Re-

search Professor, Department of Materials Science and Engi-

neering at the University of Wisconsin, 1500 Engineering Dr.,

Madison, WI 53706, 608/263-4789,

kumar@engr.wisc.edu,

www.engr.wisc.edu/centers/staff/sridharan_kumar.html.References

1. Zirconium Alloys in the Nuclear Industry, 15th International

Symposium, Sunriver, ASTM International, STP 1505, 2007.

2. T.R. Allen, R.J.M. Konings, and A.T. Motta, Corrosion in Zirco-

niumAlloys,

ComprehensiveNuclearMaterials,

Vol5,p49-68,2012.

3. C.J. Wood, Water Chemistry Control in LWRs,

Comprehensive

NuclearMaterials,

Vol 5, p 17-47, 2012.

4. M. Caro, et al., Heavy LiquidMetal Corrosion of Structural Ma-

terials in Advanced Nuclear Systems,

JOM,

Vol 65, No. 8, p 1057-

1066, 2013.

5. J. Zhang, AReview of Steel Corrosion by Liquid Lead and Lead-

Bismuth,

Corros. Sci.,

Vol 51, p 1207-1227, 2009.

6. F. Barbier andA. Rusanov, Corrosion Behavior of Steels in Flow-

ing Lead-Bismuth,

J. of Nucl. Mater.,

Vol 298, p 231-236, 2001.

7. M. Shindo,WJ. Quadakkers, andH. Schuster, Corrosion Behav-

ior of High Temperature Alloys in Impure Helium Environments,

J. of Nucl. Mater.,

Vol 140, p 94-105, 1986.

8. R.Wright, et al.,HighTemperatureBehavior ofCandidateVHTR

Heat ExchangerAlloys, 4th International TopicalMeeting onHigh

Temperature Reactor Technology, 2008, Washington, D.C.,

HTR2008-58200, 2008.

9. C. Cabet andF. Rouillard, CorrosionofHighTemperatureMetal-

licMaterials in VHTR,

J. of Nucl. Mater.,

Vol 392, p 235-242, 2009.

10. C.W. Forsberg, P. Pickard, andP.F. Peterson,MoltenSalt-Cooled

AdvancedHighTemperature Reactor for Production of Hydrogen

and Electricity,

Nucl. Technology,

Vol 144, p 289-302, 2003.

11. H.G. MacPherson, Development of Materials and Systems for

Molten Salt-Reactor Concept,

Reactor Technology,

Vol 15, No. 2, p

136-155, 1972.

12. K. Sridharan and T.R. Allen, Corrosion inMolten Salts, Molten

SaltsChemistry:FromLaboratorytoApplications,ElsevierInc.,2013.

13. D. Wilson, Corrosion Issues in Molten Fluoride Salts, Ameri-

canNuclear Society Annual Conference, Reno, NV, 2006.

ADVANCED MATERIALS & PROCESSES •

JANUARY 2014

20

Fig. 5 —

Cross-sectional images of Alloy 600 after corrosion tests in fuel-containing molten

fluoride salt performed in MSRE program at Oak Ridge National Laboratory showing the effect of Ni,

Fe, HF impurities in the salt on corrosion. (a) low Fe and Ni, (b) high Fe and Ni, and (c) high HF

[13]

.

(a) (b) (c)