for corrosion control in liquid lead and LBE environments

Ferritic-martensitic (FM) steels such as HT9, which

have an extensive database of radiation damage, and T91,

which allows for higher operating temperatures, are being

considered for LFR cladding applications

[5]

. Typical oxide

layer structures developed on these steels in LBE comprise

an outer Fe

3

O

4

(magnetite) layer and inner spinel com-

pound ([Fe, Cr]

3

O

4

) layer. A notable advancement in FM

steels for LBE applications is EP-823, developed by Russian

programs. This steel contains Si (1-1.3%) resulting in an

SiO

2

surface layer that provides improved protection in

LBE environments. Ferritic oxide dispersion strengthened

(ODS) steels such as MA956 and PM2000 containing alu-

minum also perform well in LBE environments due to the

formation of a protective alumina film on the surface. Re-

fractory metals such as W, Mo, and Ta were tested with

promising results. Flow-assisted erosion and corrosion is

an important concern in LBE and can become quite dom-

inant at flow rates above roughly 2 m/s, depending on the

steel and the temperature

[4-6]

.

High temperature gas-cooled reactors

High temperature gas-cooled reactors (HTGR) are

being considered for electricity production and as a source

of by-product process heat for powering chemical plants.

Helium was chosen as the coolant gas due to its excellent

heat transfer characteristics. The reactor gas outlet tem-

peratures have not been fully established, but temperatures

of 850°C or higher are being targeted. While helium is

inert, long-term corrosion due to its impurities such as

methane, carbon monoxide, hydrogen, carbon dioxide, and

water is an important consideration. The most critical

metallic component in HTGR is the heat exchanger.

Two alloys being considered for this application are

Alloy 617 and Haynes 230. The environmental degrada-

tion of these alloys in a helium environment was investi-

gated in Japan and Germany in the 1980s and more

recently at CEA in France and Idaho National Laboratory

in the U.S.

[7-9]

Studies show that depending on the partial

pressure of these impurities and temperature, a variety of

surface reactions can occur including oxidation, carbur-

ization, and decarburization. Ideally, a protective oxide is

desirable, but this layer should not be destroyed by carbur-

ization or decarburization

[8]

. Examples of potential surface

reactions with alloys’ metallic constituents (M, reactions

listed below) include oxidation of metal by water or car-

bon monoxide, decarburization of surface by water, and re-

duction of protective surface oxide by methane

[9]

.

xH

2

O + M = MO

x

+ x/2H

2

xCO + M = MO

2x

+ C

H

2

O + C = CO

2

+ H

2

xCH

4

+ MO x = xCO

2

+ 2xH

2

+ M

Based on thermodynamic equilibrium considerations,

regimes of environmental interaction mechanisms were

mapped as a function of carbon activity and oxygen partial

pressure. The map (Fig. 3 for Alloy 617) provides a basis

for coolant chemistry control for mitigating corrosion

[7, 8]

.

The regimes include: I: strongly reducing, II: highly oxidiz-

ing, III: stable outer oxide and stable internal carbides, IV:

strongly carburizing internally and externally, IVa: strong

external carburization with stable oxide layer. Regime III

represents the highest environmental stability where a sta-

ble surface oxide protects the alloy surface and the me-

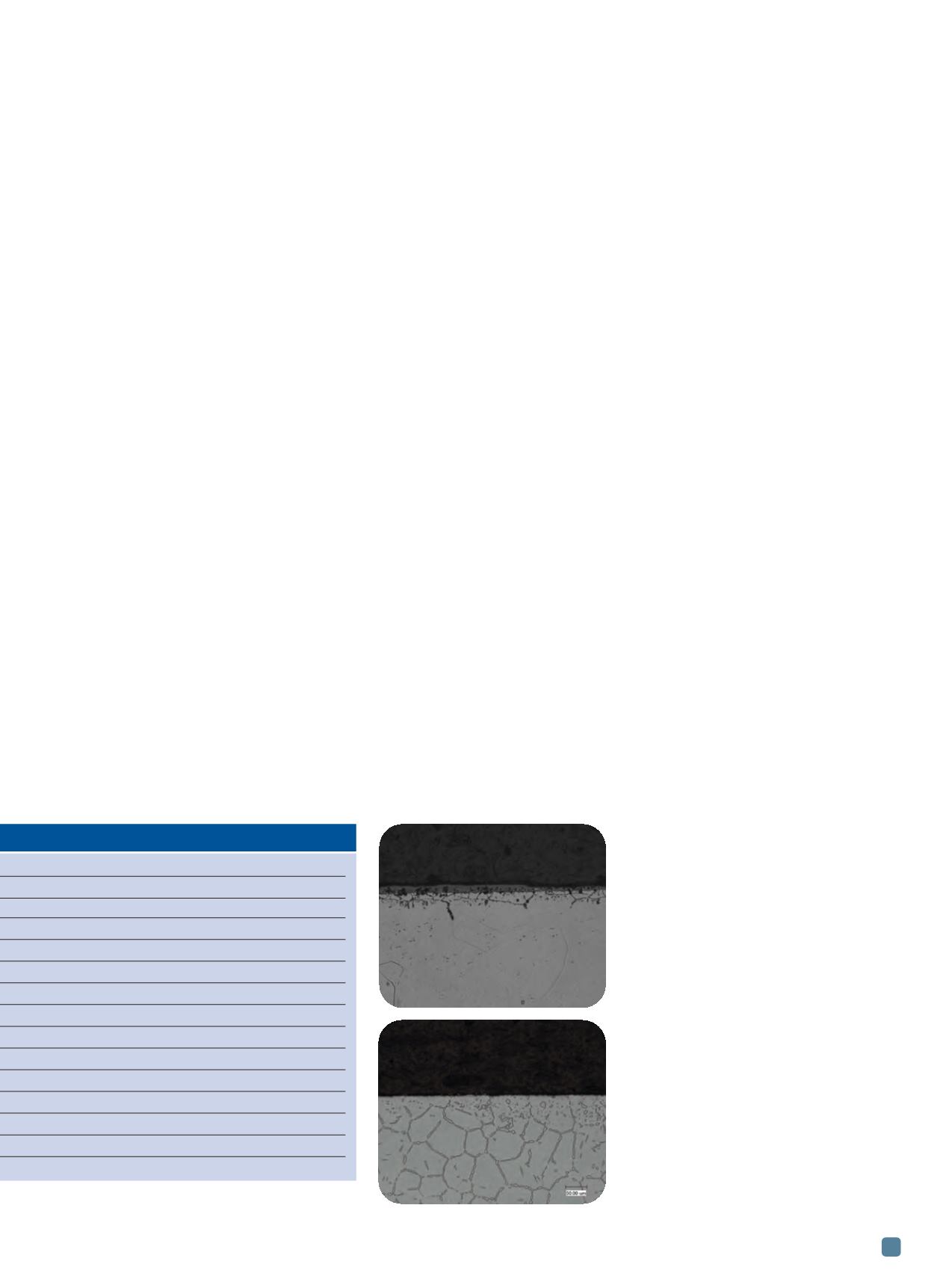

chanical integrity is maintained by stable carbides. Figure

4a and b show cross-sectional images of corrosion layers

in IN 617 after exposure at 1000°C under oxidizing and

carburizing conditions, respectively

[8]

.

Fluoride salt-cooled high temperature reactor

The high volumetric heat capacity of molten salts in gen-

eral has garnered considerable

interest for their use as a

coolant, heat transfer, and ther-

mal storage media in many en-

ergy-related applications. The

fluoride salt-cooled high tem-

perature reactors (FHR) use

molten fluoride salts as coolant.

These salts have a high boiling

point (alleviating concerns

about loss-of-coolant acci-

dents) and a high solubility for

ADVANCED MATERIALS & PROCESSES •

JANUARY 2014

19

Nb

Ti

Y

2

O

3

Co

— — — —

0.075

— — —

— — — —

— — 0.5

—

— — 0.5

—

— — — —

— — — —

— — — —

4.75-5.5 0.65-1.15 — <1.0

— — — —

0.8*

— — —

— 0.15-0.6

— —

— — — —

Fig. 4 —

Cross-sectional

images showing corrosion layers

in IN 617 after exposure at

1000°C for 500 hours (a) under

oxidizing conditions showing an

oxide layer and slight surface

decarburization, and (b) under

carburizing conditions showing

carbide phase formation at

grains and grain boundaries

[8]

.

(a)

(b)