ADVANCED MATERIALS & PROCESSES •

JANUARY 2014

17

Understanding How Materials Corrode

in Nuclear Reactors

C

orrosion of structural materials is an im-

portant consideration for both today’s

nuclear reactors and the development of

future advanced reactor concepts. Corrosion can

decrease the effective wall thickness of compo-

nents and can generate activated oxide or corro-

sion product debris particulates in reactor

systems. In conjunction with improper mi-

crostructure and tensile stress in the material it

can also lead to stress corrosion cracking (SCC).

Radiation-induced segregation (RIS) of elements

to grain boundaries can also promote SCC.

While light water reactors (LWR) use pres-

surized high-temperature water as a coolant,

other coolants such as molten metal, helium,

and molten salt are being considered for higher

temperature advanced reactor technologies

with enhanced capabilities and improved effi-

ciencies. Materials development and selection

for corrosion resistance is critical in all reactor

designs. In addition, control of coolant chem-

istry is a viable option for mitigating corrosion.

In this article, corrosion issues in four reactor

concepts that use vastly different coolant types

are reviewed.

Light water reactors

Most power reactors worldwide are LWR,

using water as the coolant and operating in the

250-350°C temperature range. Boiling water re-

actors (BWR) operate at pressures of ~7MPa,

while pressurized water reactors (PWR) oper-

ate at higher pressures (~15MPa) and temper-

atures than BWR. Zirconium alloys are used in

LWR for fuel cladding due to their high neutron

transparency. These alloys are predominantly

zirconium (~98%) with small amounts of other

constituents such as tin, niobium, iron,

chromium, and nickel

[1]

. Historically, Zircaloy-

2 and Zircaloy-4 have been used as cladding

materials. More recently, zirconium alloys such

as ZIRLO and M5 were developed for superior

corrosion resistance. In LWR environments, Zr

alloys react with high-temperature water to

form Zr-oxide and hydrogen or directly with

dissolved oxygen in water to form Zr-oxide:

Zr + H

2

O = ZrO

2

+ H

2

Zr +O

2

= ZrO

2

Oxidation of Zr cladding is a limiting factor in

achieving higher fuel burn-ups to reduce costs.

Radiation can potentially enhance oxidation

rate, an effect attributed to the creation of dif-

fusion-enhancing point defects in the oxide

layer and the radiolysis of water, which can re-

lease free oxygen

[2]

. In most cases, Zr alloys ex-

hibit uniform corrosion. Early stages are

marked by the formation of a dense oxide film

with tetragonal crystal structure, which follows

a cubic growth law and is therefore very pro-

tective. Next, a regime of columnar oxide

growth is accompanied by transformation of

the oxide to a monoclinic crystal structure.

Oxide thickness measurements of Zr alloys

from autoclave tests demonstrate a series of

cyclic patterns, each following cubic oxide

growth law during initial exposure with an

eventual transition to linear growth law behav-

ior. Micro-cracking of the oxide due to com-

pressive stresses or stresses from crystallo-

graphic transformation is attributed to this pe-

culiar growth behavior. It is evident that water

coolant chemistry plays an important role in

corrosion

[3]

.

In PWR, boron (in the form of boric acid) is

added to water to reduce core reactivity, while

LiOH is added to counteract the boric acid’s

acidic effect. Infusing lithium into oxide me-

chanically destabilizes the oxide layer and ad-

versely affects its protective qualities. Another

form of Zr alloy corrosion in BWR is nodular

corrosion, which manifests as circular nodules

in the early stages of oxidation. Thicker oxide

layers are observed on Zr alloys in the vicinity

of stainless steel and Inconel components. This

is known as shadow corrosion and is thought

to occur due to galvanic effects.

Hydrogen diffusion produced from corro-

Kumar Sridharan,

FASM*

University of

Wisconsin-Madison

The corrosion of

structural

materials and

control of

coolant

chemistry are

key factors that

impact the

lifetime of

nuclear reactors

and the

development of

future reactors.

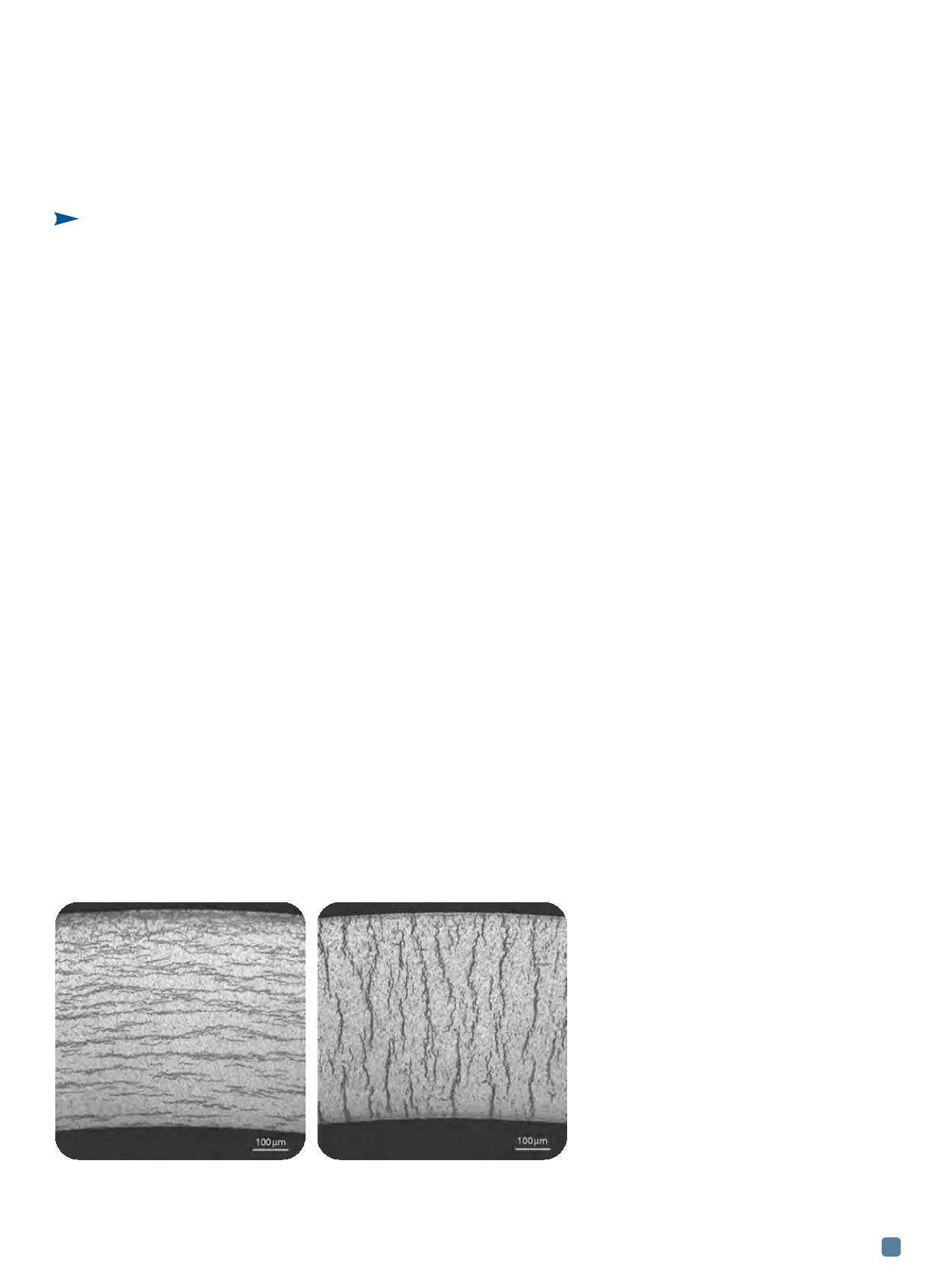

Fig. 1 —

(a) Circumferential and (b) radial hydrides formed in Zr alloy claddings as a

result of corrosion

[3]

.

(a) (b)

*Member of ASM International and ASM Thermal Spray Society