news

industry

Green magnets attract research

Researchers at Case Western Reserve University, Cleveland, received a second $1 mil-

lion federal grant to create an eco-friendly material for better power-converting magnets

in wind turbines and electric cars. The group believes it can make magnetic powder out of

inexpensive and plentiful iron and nitrogen, which can be compacted to form magnets

with the desired properties. Engineers are combining early materials science with recent

methods they developed to increase the carbon concentration in stainless steel way be-

yond the usual equilibrium solubility limit.

The Ames National Laboratory, Iowa, is providing a starting powder of specially engi-

neered spherical alloy particles. Engineers will design and build a fluidized-bed reactor at

Case to optimize the processing parameters.

For more information: David Matthiesen,

216/368-1366,

david.matthiesen@case.edu,

www.case.edu.

Why lithium-ion batteries fail

In the search for higher energy density

batteries, scientists have experimented for

more than 20 years with materials capa-

ble of repetitively alloying and de-alloying

with lithium. Laboratory-scale experi-

ments show that batteries with such ma-

terials have energy densities multiple

times that of intercalation materials; how-

ever, these alloying materials are not yet

exploited in industry due to limited life-

times. Martin Ebner, PhD student at the

Laboratory for Nanoelectronics in the

Department of Information Technology

and Electrical Engineering (D-ITET),

Zurich, explains, “Their capacity typically

fades after a couple of charging and dis-

charging cycles.” This is attributed to a massive—up to threefold—expansion of the elec-

trode material during charging. During discharge, the materials contract again, but do not

reach their original state. Electrode particles break apart, the electrode structure disinte-

grates, and the fragments lose contact with the rest of the cell.

www.lne.ethz.ch.

Tree hugging battery made of wood

An episode of the American Chemical Society’s (ACS’) Global Challenges/Chemistry

Solutions podcast series describes the development of a battery made from a sliver of

wood coated with tin. It shows promise for becoming a tiny, long lasting, efficient, and

environmentally friendly energy source. The device is 1000 times thinner than a sheet of

paper, according to researchers. It is well known that wood fibers from trees are supple

and naturally designed to hold mineral-

rich water, similar to the electrolyte used

in batteries. Researchers decided to ex-

plore using wood as the base of an exper-

imental sodium-ion battery. Using

sodium rather than lithium would make

the device environmentally friendly.

Lab experiments show the device per-

formed successfully though 400 charge-

discharge cycles, putting it among the

longest-lasting of all sodium-ion

nanobatteries.

www.acs.org/globalchallenges.ADVANCED MATERIALS & PROCESSES •

JANUARY 2014

12

E

NERGY

T

RENDS

briefs

Scientists at

Nanyang

Technological University (NTU),

Singapore, developed next

generation solar cells made of

organic-inorganic hybrid

perovskite materials. They are

about five times less expensive

than current thin-film solar cells,

due to a simpler solution-based

manufacturing process. Perovskite

is known to be a remarkable solar

cell material as it can convert up to

15% of sunlight to electricity, close

to the efficiency of current solar

cells, but scientists did not know

why or how, until now.

www.ntu.edu.sg.

Close-up of the new perovskite

solar cells made in NTU’s Energy

Research Institute. Courtesy of

Nanyang Technological

University.

Building on President Obama’s

broad-based plan to cut carbon

pollution and support clean energy

innovation across the country,

Energy Secretary Moniz recently

announced about $60 million to

support innovative solar energy

research and development. As part

of the department’s

SunShot

Initiative,

these awards will help

lower the cost of solar electricity,

advance seamless grid integration,

and support a growing U.S. solar

workforce.

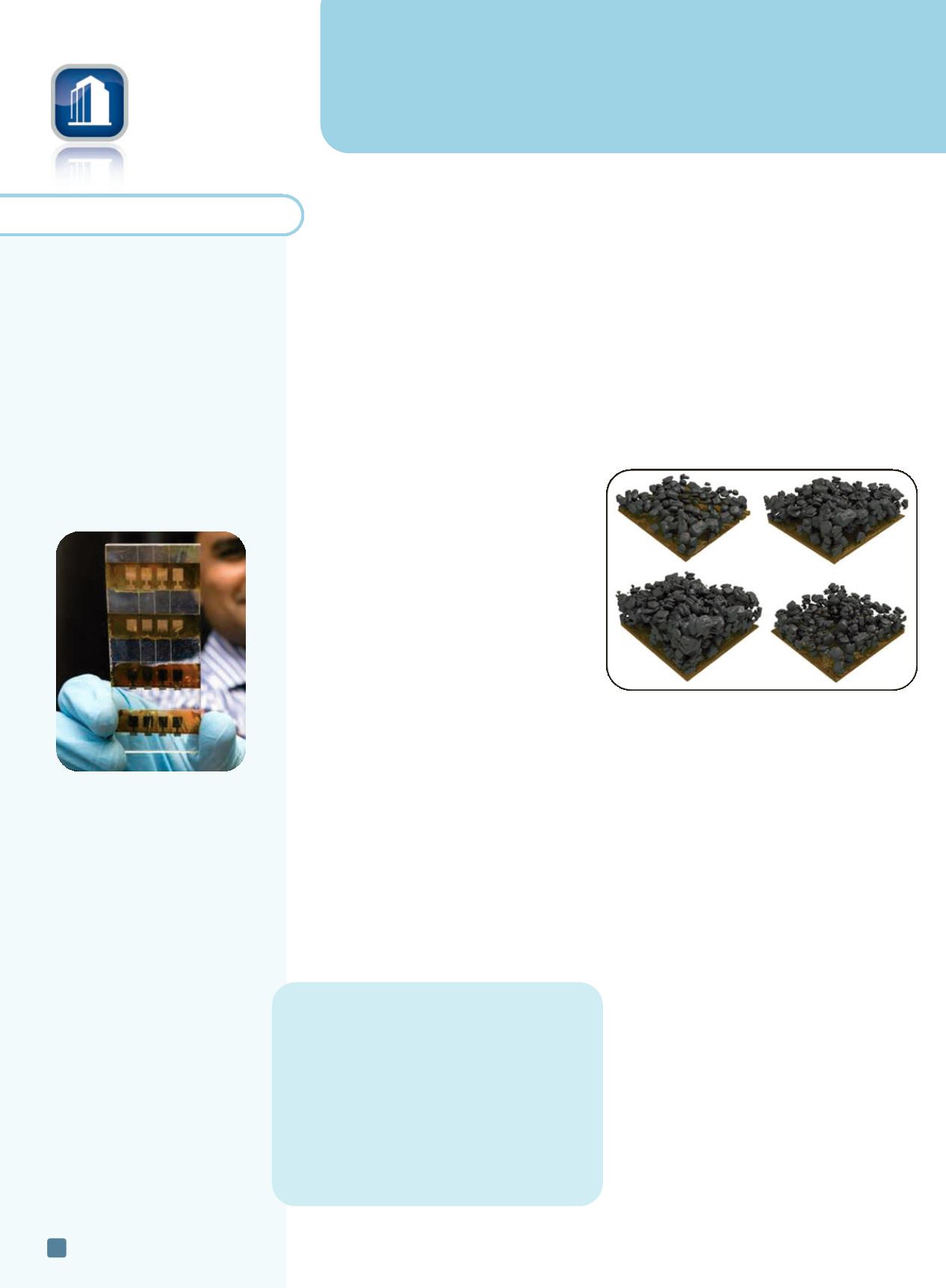

www1.eere.energy.gov/solar/ sunshot.Particles of a tin oxide electrode experiencing

structural changes during charging (1-3) and

discharging (3-4). Courtesy of Martin Ebner,

Laboratory for Nanoelectronics, ETH Zurich.

Colorado State University,

Fort Collins, researchers are

nearing the prototype phase for a lithium ion battery that

could be safer, less expensive, faster charging, and more

environmentally friendly than conventional batteries. The

team developed one component at a time—starting with

a copper foam structure purchased to serve as the current

collector on the anode side of the battery. Foam is

relatively easy to manufacture and has a 3D structure that

increases the surface area of the electrodes and brings

them closer together, thereby increasing power density.

The intricate 3D structures use the electrode material

more efficiently than a flat surface.

www.colostate.edu.

1 2

3

4