sion reactions in the Zr alloy is an

important cladding degradation

mechanism

[2]

. The hydrogen can

form a zirconium-hydride phase in a

plate-like morphology with associ-

ated embrittling effects in the

cladding. The orientation of these

hydride phases (circumferential or

radial, Fig. 1) continues to be the

subject of ongoing studies. Delayed

hydride cracking (DHC) is a particu-

lar concern when hydrides dissolve

and reprecipitate in an orientation

more favorable to crack initiation.

Other components of LWR such

as steam generator tubing, pipes, con-

trol rod drive mechanisms, core sup-

port structures, and shroud bolts are

made with materials such as AISI 304

and 316 stainless steels, and Ni-based

alloys such as Alloys 600, 690, 718,

and 800H. SCC is a concern in these

components, particularly at welds.

For 304 and 316 stainless steels, sensi-

tization dramatically promotes SCC.

Very low carbon nuclear grade (NG)

stainless steels and stainless steels

with niobium additions (grade 347)

with superior resistance to SCC have

been developed. Hydrogen is often in-

jected into the water in BWR to

negate the effect of dissolved oxygen

and reduce SCC. Alloy 600 was em-

ployed for steam generator piping,

but intergranular cracks were ob-

served after multiple years of service.

Alloy 690 with higher resistance to

SCC is being considered.

Lead fast reactors

Lead fast reactors (LFR) provide

notable benefits such as burning long-

lived actinides to shorter-lived ones,

and alleviate the challenge of long-

term nuclear waste storage. LFRs typ-

ically use a liquid Pb-Bi eutectic (LBE)

alloy as coolant. LBE has a low neu-

tron cross section, low melting point

(~123.5°C), and excellent thermal

properties. Operating temperatures

are in the 350-550°C range. Corrosion

resistance of structural materials in

contact with high temperature liquid

LBE is an important requirement in

this type of reactor. Primary corrosion

mechanisms are long-term dissolu-

tion of the alloy in liquid LBE and ox-

idation of the alloy surface from

reaction with oxygen in the LBE melt.

Ni, Fe, and Cr have solubility in LBE,

but Ni has particularly high solubility.

For this reason, Ni-based alloys may

not be suitable for this application.

Ferritic steels are being actively

considered for LBE environments. It is

desirable to have a small amount of dis-

solved oxygen in the LBEmelt to enable

a thin “self-healing” protective oxide

layer to formon the surface as a barrier

between LBE and the underlying steel.

Free energy considerations favor the

formation of Fe-, Cr-oxides relative to

PbO and BiO. Higher oxygen concen-

trations, however, can lead to thicker

andmechanically unstable oxides mak-

ing active oxygen control in the LBE

melt crucial. A typical oxygen concen-

tration window is deemed to be in the

range of 1 × 10

-6

to 1 x 10

-8

wt% de-

pending on the steel and temperature

[4]

.

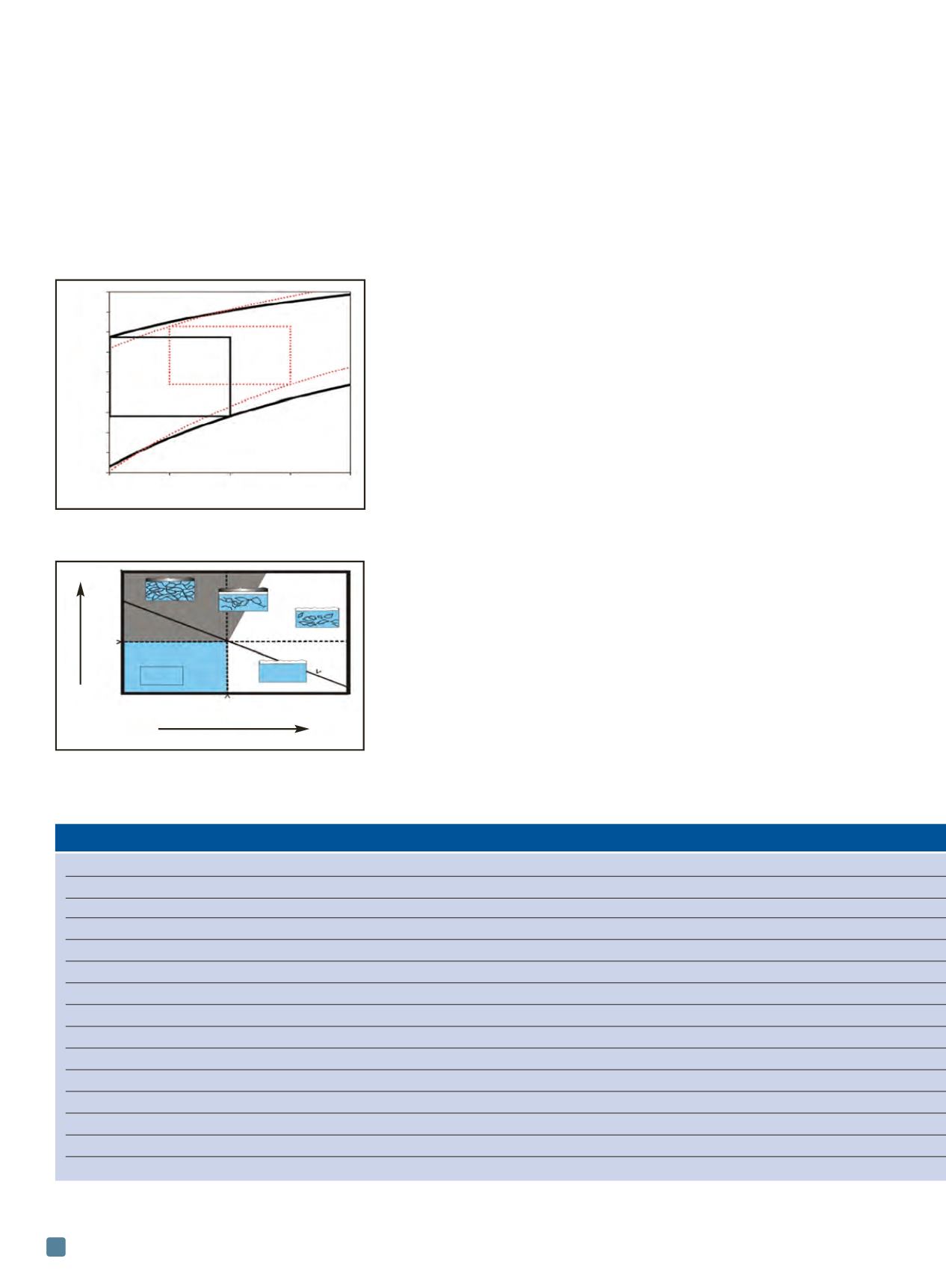

Figure 2 shows the oxygen concentra-

tion and coolant temperature regime

ADVANCED MATERIALS & PROCESSES •

JANUARY 2014

18

TABLE 1 — ALLOY COMPOSITION

Concentration, wt%

[4]

Material

Fe

C

Mn

Si

Cr

Ni

Mo

Al

V

W

HT-9

Bal.

0.18

0.4

0.2

12.26

0.49

1

— 0.3

0.46

T91

Bal.

0.105

— 0.43

8.26

0.13

0.95

— 0.2

—

EP823

Bal.

0.16

0.55

1.09

11.7

0.66

0.74

— 0.3

0.6

MA756

Bal.

0.04

— — 20

— — 4.5

— —

PM2000

Bal.

0.01

— — 20

— — 5.5

— —

316L

Bal.

0.002

1.8

0.46

17.5

12.3

2.3

— — —

Alloy 600

6.0-10 <0.15 <1.00 <0.50 14-17 Bal.**

— — — —

Alloy 690

7.0-11 <0.05 <0.50 <0.50 27-31

Bal.

— — — —

IN718

Bal.

<0.08 <0.35 <0.35 17-21 50-55** 2.8-3.3 0.2-0.8

— —

304 SS

Bal.

<0.08 <2.0

<1.0 17.5-20 8.0-11

— — — —

347 SS

Bal.

<0.08 <2.0

<1.00 18.0

11.00

— — — —

IN 800H

Bal.

0.05-0.1 — — 19-23 30-35

— 0.15-0.6 — —

Hastelloy-N 4.0-6.0 0.04-0.08 — — 6.0-8.0 Bal.

15-17

— — —

* Niobium (+ tantalum)

** Nickel (+ cobalt)

Fig. 2 —

Parameter space defined by oxygen

concentration and liquid lead and LBE coolant

temperature for corrosion control

[4]

.

Fig. 3 —

Map of carbon activity and oxygen partial

pressure showing regimes of surface corrosion

degradation mechanisms for IN 617 in high

temperature impure helium

[7, 8]

.

1.E

-02

1.E

-03

1.E

-04

1.E

-05

1.E

-06

1.E

-07

1.E

-08

1.E

-09

1.E

-10

1.E

-11

Oxygen concentration, %/wt

350

450

550

650

750

Temperature, °C

Contamination

Oxygen

Range Pb control

Range LBE

Corrosion

Partial pressure of oxygen

(log P

O 2

)

IV a

IV

a

c

III

I II

Cr metal

P

O 2

Carbon activity

(log a

c

)

P

CO