Self-correcting crystal holds promise for advanced electronics

Researchers from the National Institute

of Standards and Technology (NIST),

Gaithersburg, Md., joined with an interna-

tional team to engineer and measure a prom-

ising new class of nanostructured materials

for microwave and advanced communication

devices. Based on NIST’s measurements, the

novel materials—a family of multilayered

crystalline sandwiches—could enable an in-

novative class of compact, high performance,

high efficiency components for devices such

as mobile phones.

“These materials are an excellent example

of what the Materials Genome Initiative refers

to as materials-by-design,” explains NIST

physicist James Booth. “Materials science

keeps getting better at engineering complex

structures at an atomic scale to create materi-

als with previously unheard-of properties.”

According to NIST materials scientist Nathan Orloff, “People have created tunable mi-

crowave dielectrics for decades, but they use up way too much power.” The new materials

work well up to 100 GHz, setting the stage for the next generation of advanced communi-

cations devices.

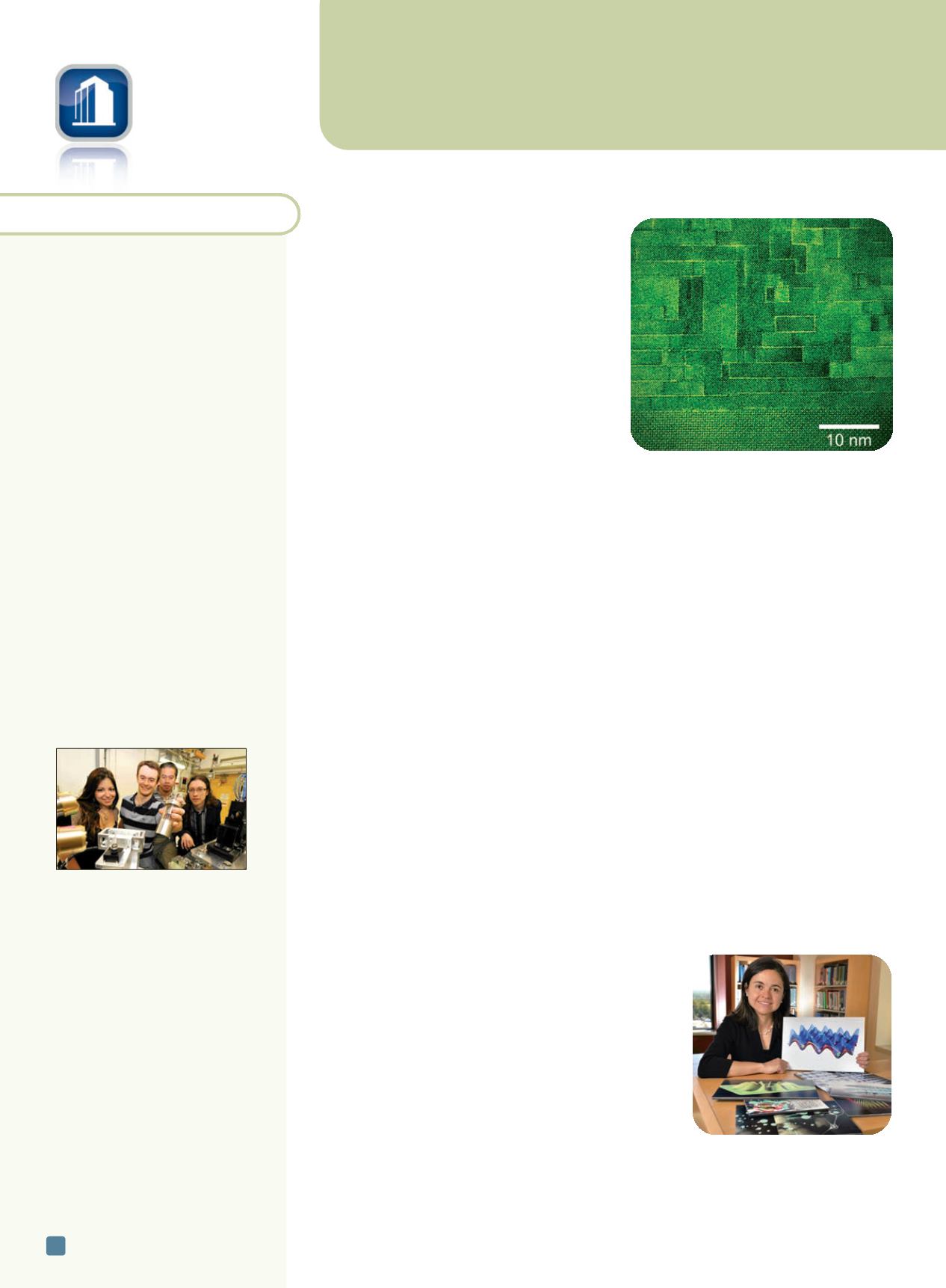

Modern cellphone dielectrics use materials that suffer from defects within their crys-

tal structure, which interferes with the dielectric properties and leads to power loss. One

major feature of the new materials, says Orloff, is that they self-correct, reducing the effect

of defects in the part of the crystal where it counts.

The new material has layers of strontium oxide, believed to be responsible for the self-

correcting feature, separating a variable number of layers of strontium titanate. Layers are

grown as a thin crystalline film on top of a substrate material with a mismatched crystal

spacing that produces strain within the strontium titanate structure that makes it a less

stable dielectric, but one that can be tuned.

The new sandwich material performs so well as a tunable dielectric, over such a broad

range of frequencies that the NIST team had to develop a new measurement technique to

measure its electronic characteristics. “We were able to characterize the performance of

these materials as a function of frequency running from 10 hertz all the way up to 125 gi-

gahertz,” says Orloff. “This material has a much lower loss and a much higher tunability for

a given applied field than any material we have seen.”

www.nist.gov.Research aims to model

behavior of ultra-cold atoms

Ana Maria Rey, a National Science Foundation

(NSF)-funded scientist and research assistant professor

at the University of Colorado Boulder’s Department of

Physics is a recent recipient of one of the prestigious

MacArthur fellowships, a $625,000 award popularly

known as a “genius” grant.

Since 2008, Rey also received about $500,000 in NSF

funding for work that includes modeling the behavior of

ultra-cold atoms and polar molecules. She and her col-

leagues create artificial materials by trapping atoms

with light. This research could lead to new materials for

more effective superconductors, as well as new mag-

briefs

The

state of Texas

recently

awarded $1 million to the new

Oil

& Gas Materials Technology

Center,

part of

Element Houston.

The center, located on a 5.3-acre

campus adjacent to the Houston

energy corridor, will use the funds

to research applications of high

performance polymers for energy

applications. The $5 million

laboratory, Element’s largest single

site investment, also offers

advanced fracture mechanics and

corrosion testing.

www.element.com.

The

University of Manchester,

UK, received a

Queen’s

Anniversary Prize

for its efforts to

support strategic development in

advanced materials and

manufacturing. The award

recognizes the university’s

expertise in developing new

techniques for 3D imaging of

material structures and defects,

and interpreting the state of stress,

microstructure, and damage in

engineering materials and

components.

www.manchester.ac.uk.

Researchers at the University of

Manchester recently received a

Queen’s Anniversary Prize.

What is known to be the biggest

and most advanced wind energy

testing facility in the U.S. is now

open in North Charleston, S.C.,

supported by a $47 million

Department of Energy

grant and

$60 million in outside funding. Led

by

Clemson University’s

Restoration Institute,

the facility

will test and validate new turbines.

Machinery that converts both

onshore and offshore wind to

electricity will also be tested.

Engineers will be able to simulate

20 years’ worth of wear and tear

on drivetrains in just a few months.

www.clemsonenergy.com.

ADVANCED MATERIALS & PROCESSES •

JANUARY 2014

8

T

ESTING

C

HARACTERIZATION

news

industry

Electron microscope image of a cross

section of the newly characterized tunable

microwave dielectric shows thick layers of

strontium titanate “bricks” separated by thin

“mortar lines” of strontium oxide that help

promote largely defect-free brick growth.

Courtesy of David Mueller.

Ana Maria Rey of the University of

Colorado Boulder received a

MacArthur Fellowship in 2013 to

study the behavior of ultra-cold

atoms. Courtesy of Casey Cass.