ADVANCED MATERIALS & PROCESSES •

JANUARY 2014

9

netic behavior that could speed up computer develop-

ment. One of the eventual goals, for example, is to de-

velop new materials that superconduct at room

temperature, rather than only in extreme cold.

“This will help everything, because nowadays you

have to cool the materials down, which is very expen-

sive,” she says. “If we don’t have to cool them down,

everything that uses superconductivity can be made

much less expensively.”

Rey is also developing a comprehensive theoretical

framework for an optical-lattice quantum computer

based on alkaline earth metals, and she has proposed so-

lutions for problems associated with storing, addressing,

and transporting qubits, the quantum equivalent of tra-

ditional computing bits. Among other things, she hopes

to resolve long-standing obstacles to large-scale entan-

glement between atoms, which quantum computers re-

quire for both communication and calculations. Such

research could produce smaller and faster computers

with capabilities that classical computers do not now

have.

For more information: Ana Maria Rey, 303/492-

7801,

arey@jilau1.colorado.edu,

www.colorado.edu.

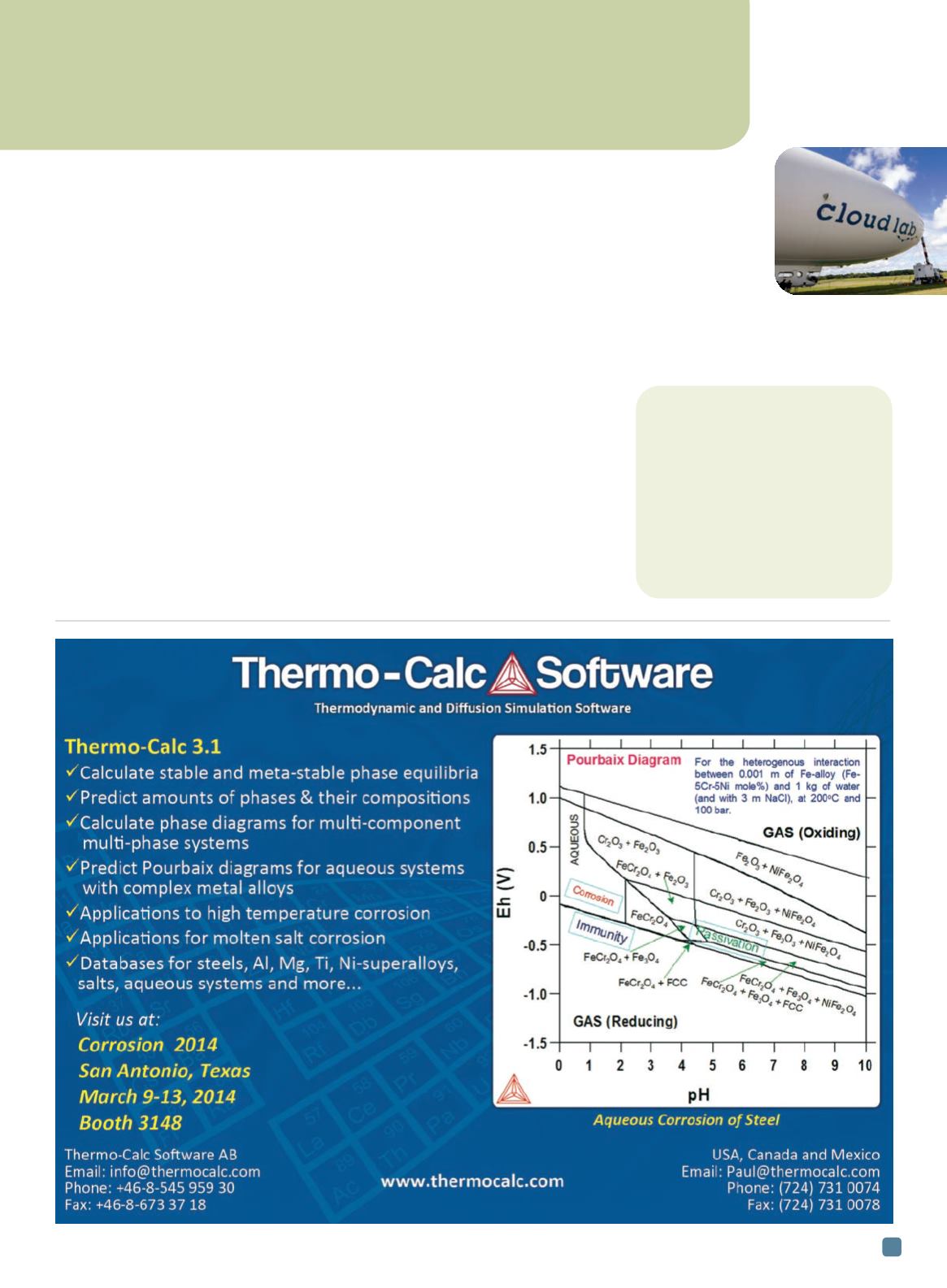

Brits use blimp to study clouds

A team of British scientists recently traveled

across the U.S. in the world’s largest blimp—Sky-

ship 600—as part of a BBC expedition team to

study clouds as well as biological activity in the

air. Microscopes from Carl Zeiss Microscopy

LLC, Germany, were used in the research activities. Researchers traveled

from Florida to California, stopping at 13 different air fields along their

route. Carl Zeiss Microscopy loaned an inverted, compound microscope

(Axio Vert.A1) and a stereo microscope (Stemi 2000) to the temporary

labs set up at the air fields.

The main goal was to ex-

plain changes in weather

and its effects. Also, data

was correlated to current

weather, migratory, and

wildlife patterns. The

Cloud Lab will be seen on

BBC Two television later

this year.

www.zeiss.com,

www.airshipsonline.com/ airships/ss600.EWI,

Columbus, Ohio, developed a new tool

called EWI SpotSight to reduce the need for

destructive testing of spot welds in manu-

facturing. The tool employs matrix-phased

array-based ultrasonic imaging technology

to accurately evaluate the effectiveness of

component joints by visualizing weld images

with real-time feedback. Originally devel-

oped for the automotive industry, SpotSight

can be used in many applications for struc-

tural inspection of metal, plastic, braze, and

composite joints.

www.ewi.org.