T

he oil and gas industry is focusing on

deepwater exploration for developing

reserves of natural oil and gas, as “easy”

reserves are becoming scarcer. The trend to-

wards deeper, colder, and more extreme envi-

ronments within recent years is demonstrated

by discoveries of mega-fields such as that off

the shores of Brazil. According to a report by

Douglas-Westwood in 2013, more than $232

billion will be spent on deepwater projects be-

tween now and 2020. Such a substantial invest-

ment hints at the anticipated challenges that

companies involved in exploration and produc-

tion expect when accessing oil at depths of any-

where up to 2 miles below sea level.

While the projection highlights the most

obvious challenges as financial in nature—such

enterprises are more costly than onshore or

fixed offshore operations—few alternatives

exist. With rapidly emerging economies such as

China and India, global energy demand shows

no sign of stopping, with oil as the dominant

source of power for the near future. The single

greatest challenge oil producers face when ex-

tracting deepwater oil is not an economic one,

but rather a technical hurdle.

The environment of fields found at

depths of 1.25 miles and deeper make

deploying standard equipment unfeasi-

ble. For example, these fields have un-

usually high levels of CO

2

that can occur

in the production stream, which comes

out of the reservoir in a super-critical

state, at a temperature exceeding 88°F

(31°C) and pressure of 74 bar. In this

state, the CO

2

exists as a dense phase

fluid, displaying characteristics of both

liquid and a gas, and poses difficulties

for equipment used to transport oil

from the well to the surface. Valves and

blowout preventers are attacked by

super-critical CO

2

, but also damagingly

high levels of corrosive H

2

S found in

deepwater environments.

This CO

2

can be useful if injected

back into the reservoir to reduce oil vis-

cosity and assist its flow back to the well.

Using such full-field subsea separation

and boosting and injection systems, the

Statoil Hydro-operated Tordis field in the

North Sea increased recovery by an extra

35 MMbo (millions of barrels of oil) and

extended the life of the field by 15 to 17

years in 2007. At higher temperatures and pres-

sures in deeper water, longstanding issues of cor-

rosion, pressure, and temperature all pose greater

problems for compressors and other components.

Elastomer selection and qualification

Element Material Technology, St. Paul,

Minn., is currently involved in the research, de-

velopment, and qualification of next-generation

materials designed to offset problems posed by

deepwater extraction. Elastomers are being

considered due to their flexible and pliant na-

ture, which makes them well suited as sealing

components. The team was recently ap-

proached by a client seeking to operate in a field

discovered off the coast of Brazil at a depth of

1.25 miles in order to characterize a range of

advanced elastomers.

At this depth, elastomers are more suscep-

tible to chemicals and can become structurally

altered. The valves and components are in con-

tact with oil and gas at temperatures of 248°F

(120°C) and must contend with high pressures

and rapid gas decompression events, so qualifi-

cation and selection of the best materials for

this environment is critical.

Seven well characterized primary products

were selected for qualification to deliver opti-

mum performance and to represent the full

range of three core varieties of elastomers—hy-

drogenated nitrile butadiene rubber (HNBR),

fluoroelastomer (FKM), and perfluoroelas-

tomer (FFKM). Each elastomer type has partic-

ular strengths—FFKM is particularly suited to

high temperatures and chemically aggressive

environments, while HNBR performs well at

lower temperatures. FKM has good resistance

to thermal and chemical environments and gas

decompression events.

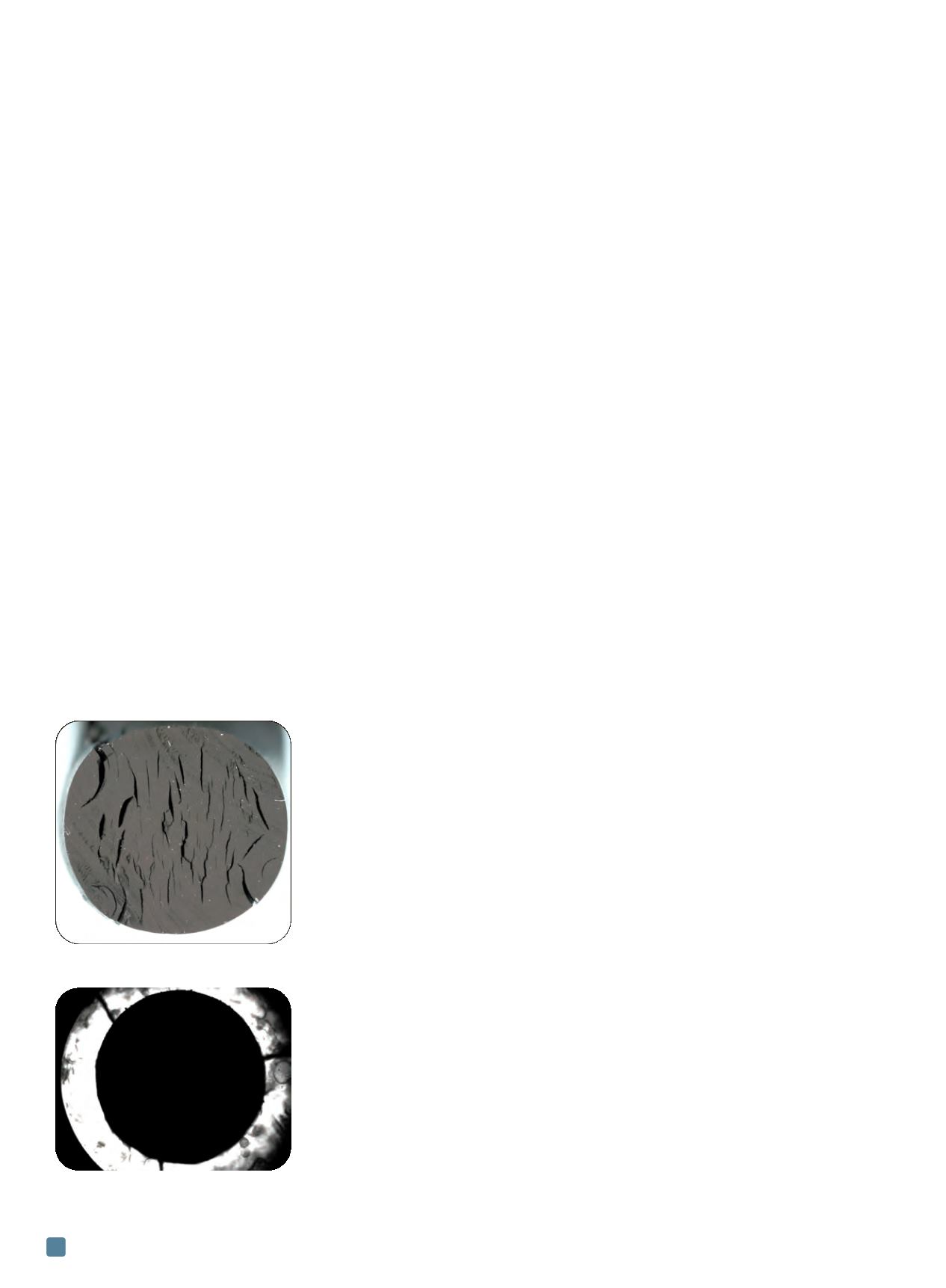

Rapid gas decompression and pressure resist-

ance are primary concerns when selecting a par-

ticular elastomer for these components. However

advanced the material may be, under pressure

and over time, damaging chemical elements such

as super-critical CO

2

andH

2

S will diffuse into the

polymer and permeate through it. If rapidly de-

compressed, the change in pressure means gases

are forced out of the material, potentially causing

blistering or cracks as they escape, as seen in

Fig. 1. Under constant pressure, fluid diffused

into the material can cause swelling and weaken-

ing, potentially causing leakage.

To overcome this issue, elastomers are

Advanced Elastomers

for Deepwater Oil Exploration

Through

rigorous

testing and

qualification,

advanced

materials

enable major

oil companies

to operate in

ever more

extreme

environments.

ADVANCED MATERIALS & PROCESSES •

JANUARY 2014

26

TECHNICAL SPOTLIGHT

Fig. 2 —

Super-compressed CO

2

at

pressure and temperature surrounding

the elastomer during decompression.

Fig. 1 —

Typical decompression failure

of FKM material.