ADVANCED MATERIALS & PROCESSES •

JANUARY 2014

29

Iron production in the new United States in-

creased from these 30,000 tons at the beginning

of the American Revolution to 54,000 tons from

153 furnaces by the 1810 census. The slow growth

was largely due to a general lack of industrializa-

tion in America: Per capita iron consumption

hardly changed in this 35-year span. Another fac-

tor keeping growth in check was the relatively in-

expensive iron imported from England. It was

cheaper to make iron from coke in Britain and

ship it to major East Coast port cities than to con-

tinue using charcoal in the inland U.S. plantations

and then transporting finished iron to growing

population centers.

Philadelphia and the canal systems

The beginnings of a solution to the English im-

port problem came about because the city of

Philadelphia was desperately seeking a way to pre-

vent the influx of farm products and manufactured

goods from areas north and west of the city using

the Susquehanna River to ship from Baltimore.

Philadelphia was the largest port in the newU.S. and

its politicians were battling to maintain this position

against New York City and nearby Baltimore. Top

priority was to capture the local trade leaking out to

Baltimore and to transport energy resources from

the new anthracite coal mines from the region in

Pennsylvania’s northeastern corner to metropolitan

areas along the coast. The only solution to bulk

transportation at this point was by water. While

there were many natural streams in this corner of

Pennsylvania, they contained numerous obstacles to

navigation. This meant building canals.

Canals were not new to America, as they had

been dug in New England with some effective-

ness. With the successful attempt to build one

across upstate New York all the way to Lake Erie,

a project just coming to completion in the mid-

1820s, many attempts were undertaken to build

them throughout the country. One of the most

profitable was the Delaware and Hudson Canal,

built with private capital.

This canal system was masterminded by three

brothers by the name of Wurts, who had tied their

future to that of the anthracite coalfields behind

Moosic Mountain in the Scranton, Pa., area. Yet

two major problems existed—finding a way to get

the coal out of the wilderness of Northeast Pa. and

down to the cities on the coast, especially New

York, and convincing people that anthracite coal

(known as stone coal) was an acceptable fuel. The

Wurts brothers believed if they could get the coal

to New York at a reasonable cost, its value would

soon sell itself, a belief shared by their ally Philip

Hone, then mayor of New York City.

Technical expertise for the project came from

Benjamin Wright, chief engineer of the Erie Canal.

The logical route for the new canal was across the

Delaware River into New York, northeast up the

valleys west of the Shawangunk Mountains, down

Rondout Creek to Kingston, New York, and then

through the Hudson River. It was a natural water-

way, even though it meant the canal went north-

east when New York City was southeast.

Other canals were built on the Susquehanna,

Schuylkill, Lehigh, and Delaware Rivers. The Union

Canal system linked the Susquehanna and the

Schuylkill with the coal fields above Reading, Pa.

With the sudden availability of anthracite coal in

Southeastern Pa., the ironmasters soon learned to

adapt it to their blast furnaces. The hard coal did

not have to be processed to coke and was usable di-

rectly from the mine. Just as coke had revived the

British iron industry a century earlier, anthracite

coal accomplished the same result for the iron in-

dustry in Southeastern Pa. The industry had been

in a long period of decline because it was running

out of wood. This strategy of improved water trans-

portation with the fortuitous application of an-

thracite coal in ironmaking worked sufficiently well

to allow this region to become the first major iron

producer in America.

The passage of a half-century and a Civil War

would occur before Pittsburgh would replace

Philadelphia as the leader in ironmaking. During

this time, Philadelphia would begin manufacturing

the mill machinery and building the factories for

products made of iron, thereby serving as a major

incubator for the American Industrial Revolution.

For more information:

Charles R. Simcoe can be

reached at

crsimcoe@yahoo.com. For more metallur-

gical history, visit

www.metals-history.blogspot.com.

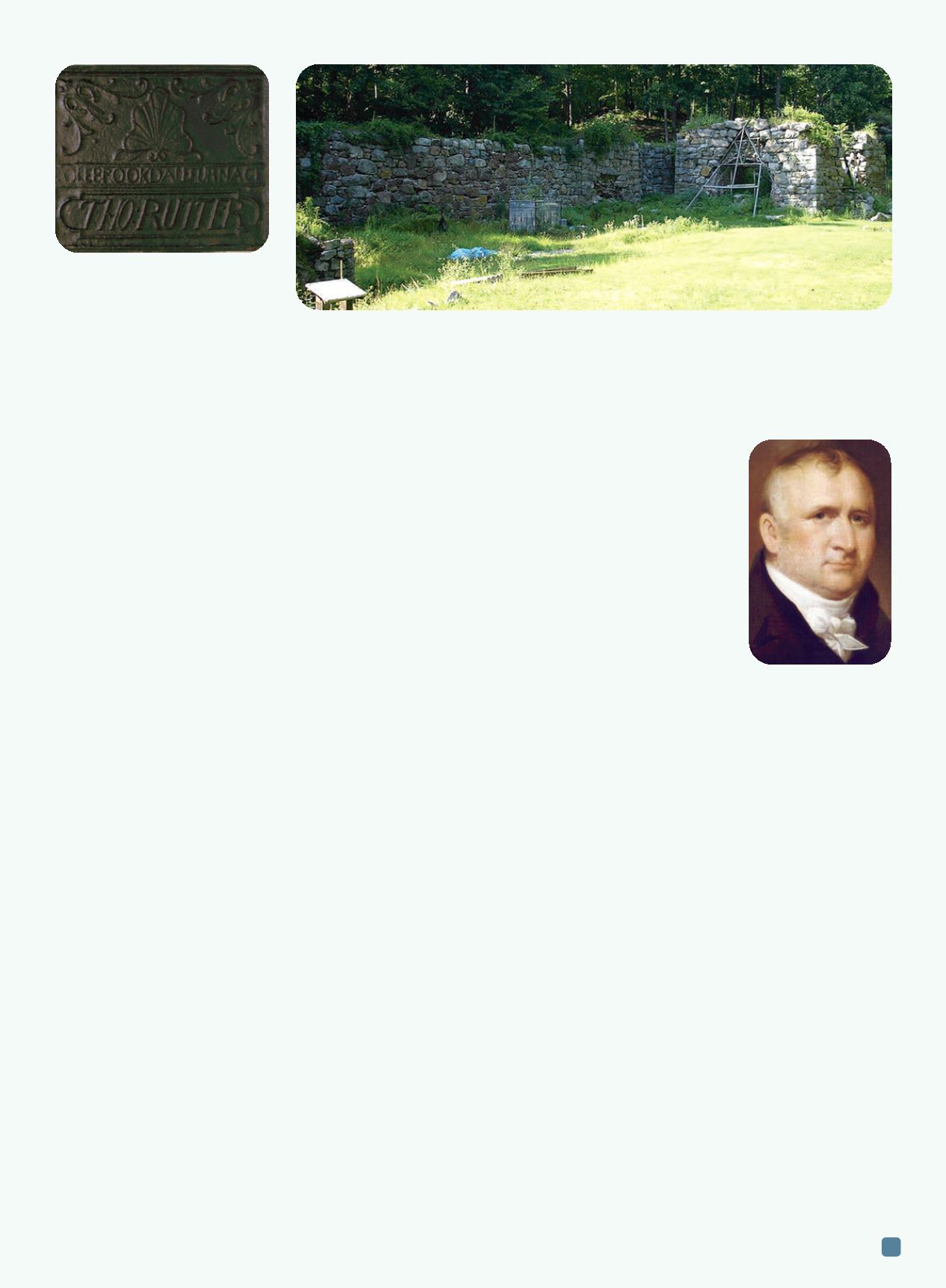

Peter Hasenclever’s

Long Pond Ironworks,

N.J., a furnace from the

Civil War era. Courtesy of

KForce at en.wikipedia.

When the Erie Canal

was funded in 1817,

Benjamin Wright

became the chief

engineer who directed

the successful

completion of the

greatest artificial

waterway in the world.

Courtesy of Francis

Delafield Wright III;

www.marblecemetery.org.

A cast iron stove plate made at

Colebrookdale Furnace, Pa., circa

1765. Courtesy of the State Museum

of Pennsylvania.