edfas.org

13

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 18 NO. 4

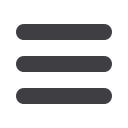

is usually caused by a very subtle defect that may be very

difficult tofind. Tomaintain a highPFA success rate for soft

failures, fault isolation is often performed prior to destruc-

tive PFA. In this case, LVI and LVPwere again employed for

the fault isolation. The LVI image of the clock signal and

the data signal for a reference scan chain, SO3, and the

failing scan chain, SO5, is shown in Fig. 15. It shows that

the clock signal (in yellow) appears to be acceptable in

both scan chains, while the data signal (in blue) stops at

the latch callout for SO5 and continues to propagate for

Fig. 14

FIBcross sectionshowinghollowV2 in the clock signal

line from the clock buffer to the latch callout

Fig. 15

LVI image of data signal and clock signal for a

reference scan chain, SO3, and the failing scan chain,

SO5, indicating a broken point at the latch callout for

the failing scan chain, SO5

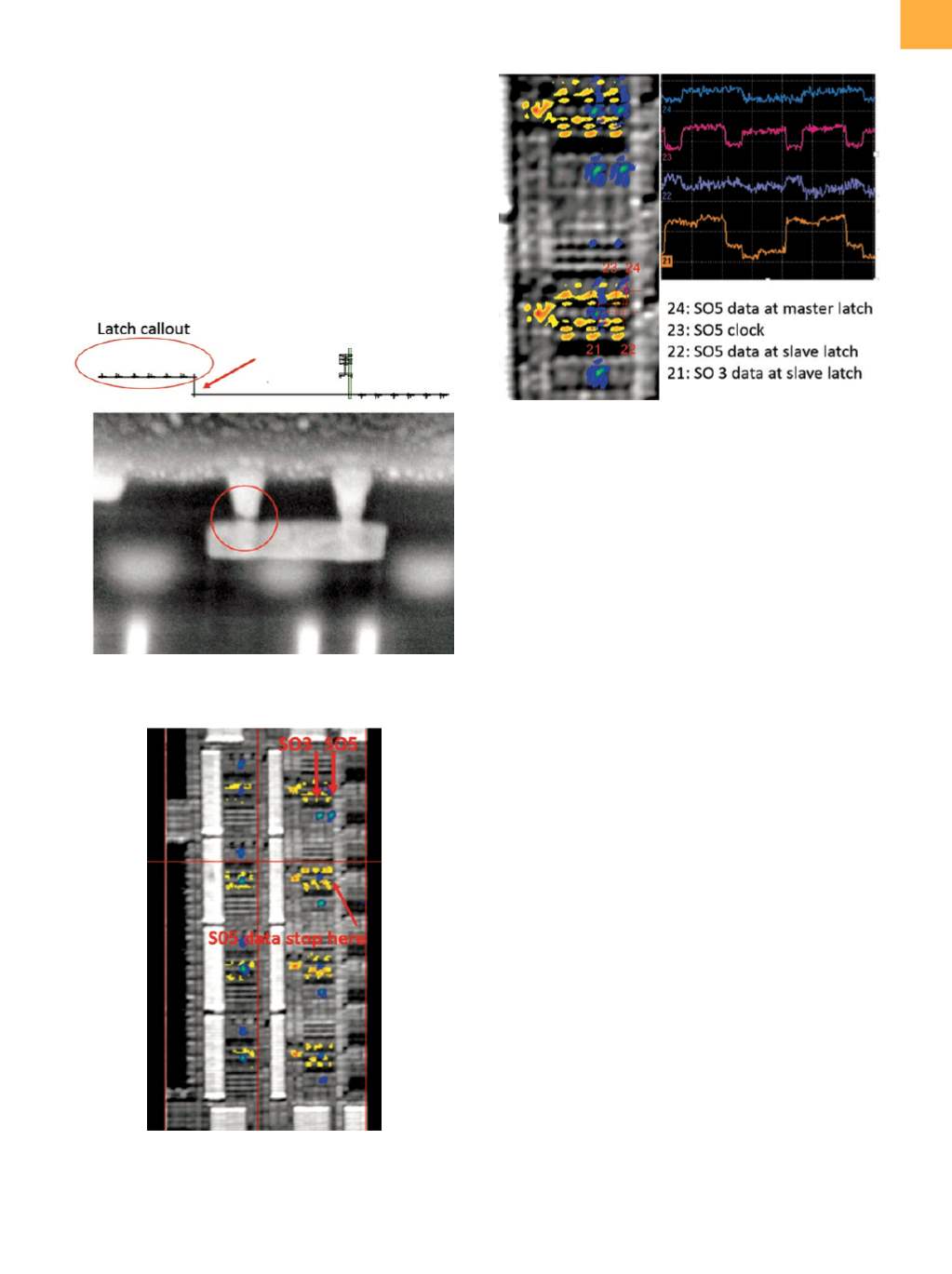

Fig. 16

LVP waveforms from the master latch of the latch

callout, the slave latch from the latch callout, and

the adjacent reference latch, indicating datamissing

at the slave latch for the latch callout

SO3. The higher-resolution LVI image (Fig. 16) from the

feeding latch and the latch callout showed that the data

actually had propagated to the master latch of the latch

callout but had not transferred to the slave latch. This

was further verified with LVP waveforms collected from

the master and slave latches, as shown at the right in Fig.

16. The subsequent PFA found a gate-to-source-resistant

short defect, which was responsible for the scan chain

single-latch soft failure.

SUMMARY

The unique capability of LVI to map periodic signal

propagation makes it very useful in scan chain diagno-

sis. For scan chain clock-type failures or single-latch soft

failures, routine PFA with top-down SEM inspection often

found no defect. Laser voltage imaging can clearly show

the broken point of the clock signal or data signal for

these failures. Follow-up LVP probing can further confirm

the failing nodes and help explain the failure signature.

Employing LVI and LVP in the diagnostic analysis greatly

improves the in-line scan chain logicmacro failure analysis

success rate.

ACKNOWLEDGMENTS

TheauthorsappreciateThuySuandLarryBreitenberger

for their help in physical failure analysis, and Christopher

Hodge, Manuel Villalobos, and John Sylvestri for their

diagnostic test and imaging assistance.

REFERENCES

1. S. Naik, F. Agricola, and W. Maly: “Failure Analysis of High Density

CMOS SRAMs,”

IEEE Des. Test. Comput.,

1993,

10

(2), p. 13.