edfas.org

edfas.org

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 18 NO. 2

48

SEALANT/CAULK MATERIAL AIDS DECAPSULATION

OF ELECTRONIC COMPONENTS

Contributed by Bill Ross, Pelseal Technologies, LLC

bross@pelseal.comE

ngineering research company ACI Technologies is

tasked with decapsulation of electronics compo-

nents for testing and investigative purposes. In the

normal method of decapsulation, an analyst uses a rotary

tool to drill a small indentation in the hermetic sealant

material and then applies nitric acid to eat through the

polymeric encapsulant.

The company performs this decapsulation for a

number of purposes, including wire bond inspection,

operational testing, and counterfeit investigation. This

Most failure analysis labs are challenged by newproblems and existing equipment. Old techniquesmust bemodi-

fied to be effective on new technology.

EDFA

readers are encouraged to submit examples of master FA techniques

for future publication.

testing method allows the operator to explore a silicon

die while it is still on a functioning board. Typical pieces

being tested are 5

×

5 mm in size.

THE PROBLEM

In the traditional method of decapsulation, the opera-

tor makes a small well above the location of the die and

places the component in a tin tray on top of a 140 °C hot

plate. The operator adds nitric acid in a dropwise fashion

into thewell to allowdigestion of the packagingmaterial.

MASTER FA TECHNIQUE

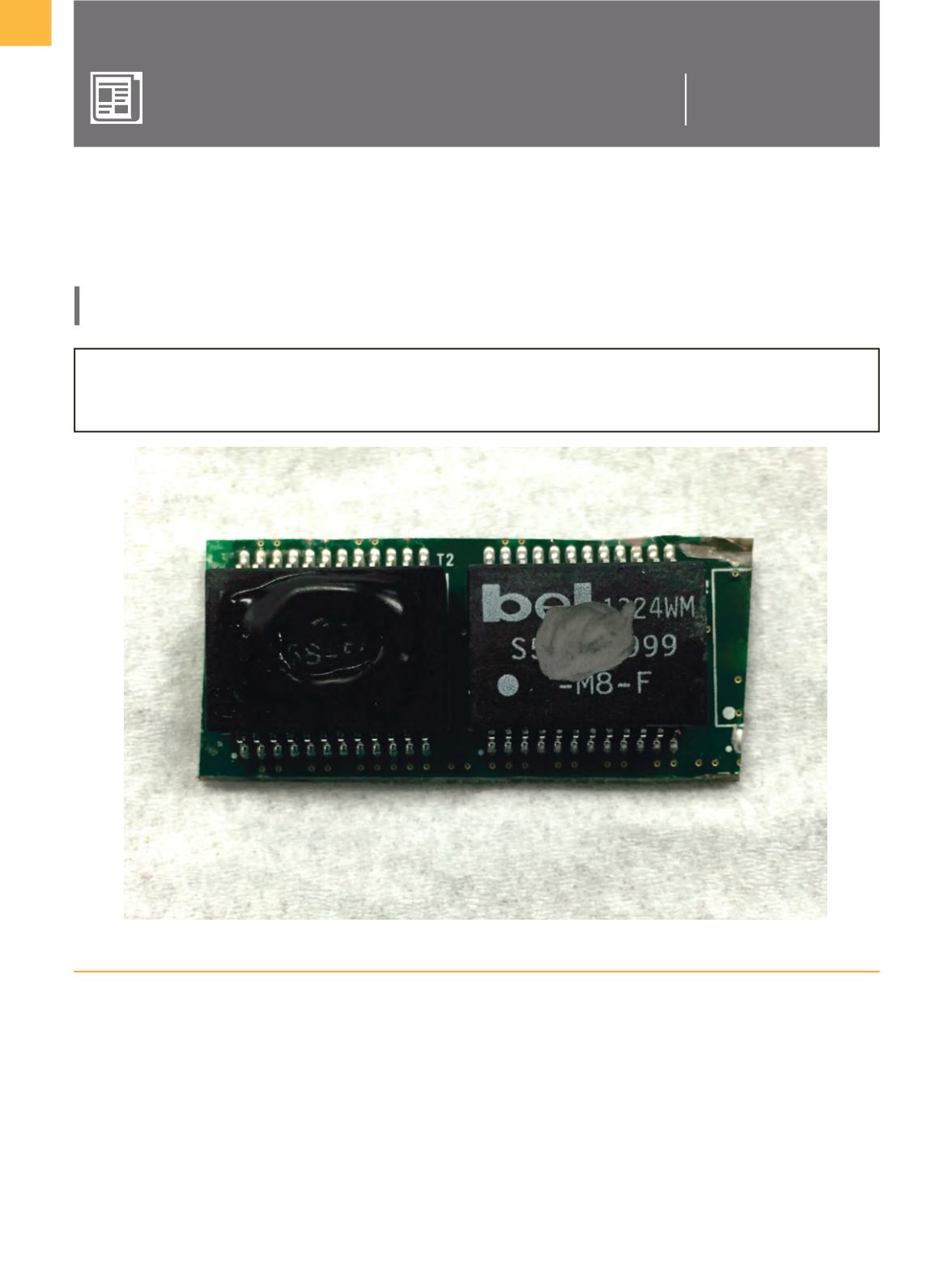

Two identical (side-by-side) components with caulk well on the left and carved well on the right.

Photo courtesy of ACI Technologies