edfas.org

edfas.org

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 18 NO. 1

8

Fig. 6

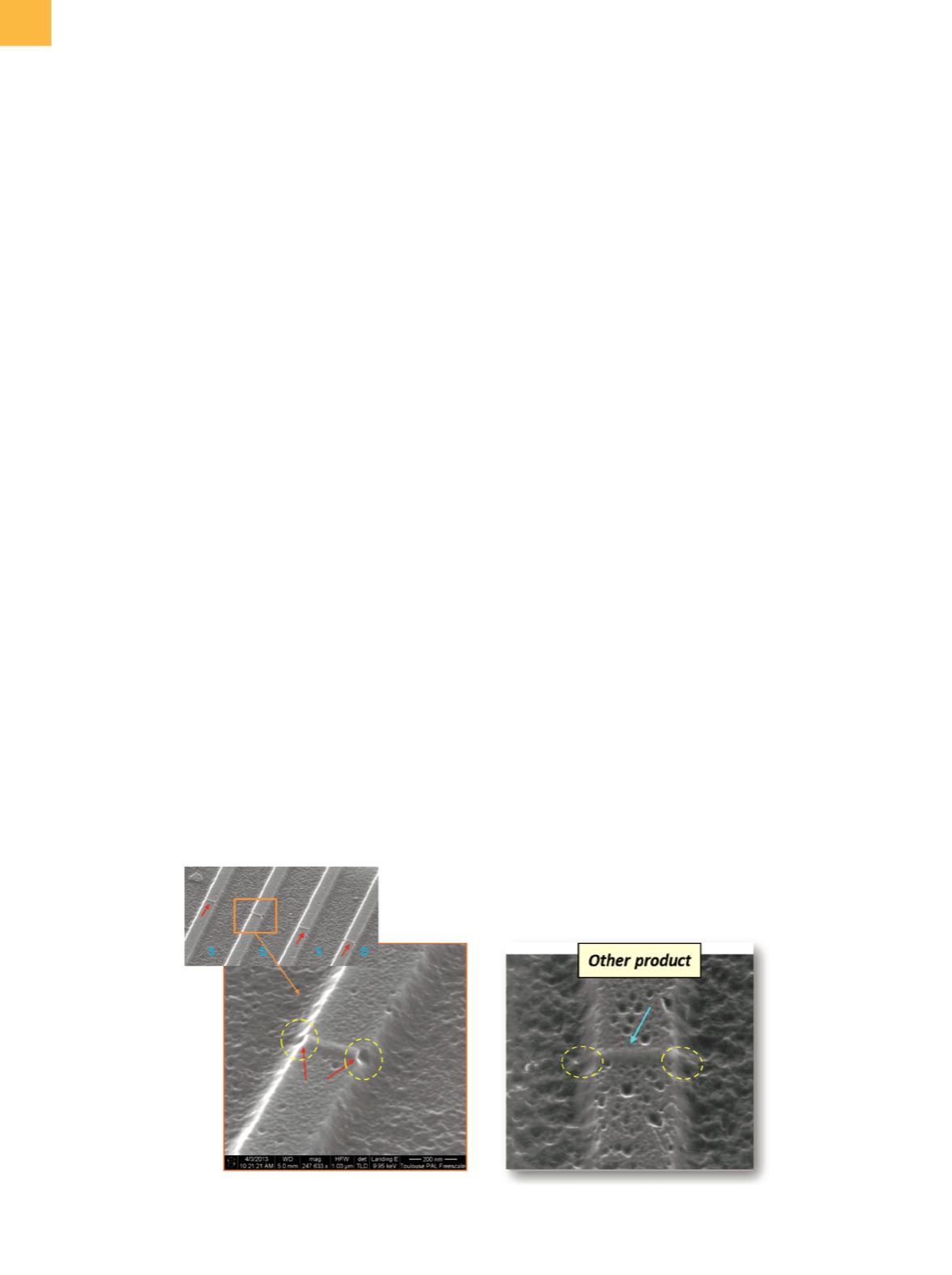

Tilted SEM image after Wright etch delineation on different product

hairline is suspected to be unexpected

n

-doped silicon at

the surface of the

p

-doped channel. The PVC images were

obtained using high-resolution SEM with sample tilt and

beamdecelerationmode (consisting of the application of

a positive voltage to the sample holder). This configura-

tion is highly recommended to detect pipeline defects by

improving the collection of secondary electrons.

SILICON CRYSTALLINE DELINEATION ETCH

To verify the PVC contrast at the silicon substrate level,

a silicon delineation etchwas performedwithWright etch

solution;

[8]

the

p

-type etch rate is higher than the

n

-type

area etch rate

[9]

with this delineation etch. After etching

with Wright solution for 2 s, the failing NMOS device was

inspected with an SEM; a bump was observed at the

dark line location previously observed on the PVC image

(Fig. 6). This topographic anomaly is consistent with the

hypothesis of an abnormal presence of an

n

-type area in

the NMOS channel (

p

-doped). This unexpected

n

-doped

area crossing the whole channel width explained the

NMOS source-to-drain leakage. In addition to its dopant

delineation capability, Wright etch is also widely used to

delineate silicon crystalline defects, creating typical etch

pit signatures. Those etch pits were observed at the edges

of the abnormal silicon bump and revealed the dopant

anomaly associated with a crystalline defect

[2]

(circled in

yellow in Fig. 6). To confirm and better understand this

complex defect, more investigationswere performedwith

advanced FA techniques.

AFM/SMM TECHNIQUE

Apart fromcase 2was selected to continue the analysis

on the pipeline signature. Surface topography measure-

ments using AFM did not reveal a conclusive anomaly at

the silicon level (Fig. 7). However, SMM analysis showed

an anomalous line contrast in the dC/dV response image,

which typically provides information about the doping

levels. The dark lines observed through the channels of

Mf2 (red arrows in Fig. 7) indicate an unexpected doping

response in the channel active area. These results were

consistent with physical delineation etches that gave

similar pipeline results (see Fig. 6 from the part in case 1).

In contrast, the same techniquewas applied on the failing

device in case 3, where silicon dislocations were found by

physical delineation etch and TEM analysis (refer to the

next section). In this case, SMM was not able to highlight

a defect signature (Fig. 8); this suggested that the nature

of the defect is different. Presumably, the threshold con-

ductivity of free carriers is not in the detection range of

SMM as compared to a pipeline defect, even if the defect

is considered to be conducting.

PLANAR TEM ANALYSIS

Based on previous findings, TEM characterization

was required. Planar TEM samples were prepared on the

defective parts of each product. In case 2 (with pipeline),

TEM images showed crystallographic defects in active

areas, at the vicinity of the anomalous lines observed

during SMM analysis (Fig. 9). The crystalline defects were

noncontinuous lines that were only localized in gate areas.

The defects were perpendicular to source-drain fingers

and appeared to be very close to the surface. Also, con-

tinuous lines were observed in the trench area (shallow

trench isolation), nearly in the extension of the discon-

tinuous lines (far left in Fig. 9). In this case, it was found

to be a pipeline defect in the active area. In case 3, TEM

images also showed crystallographic defects in the active

areas. However, the defects were long, continuous lines