edfas.org

edfas.org

7

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 18 NO. 1

(a)

(b)

Fig. 3

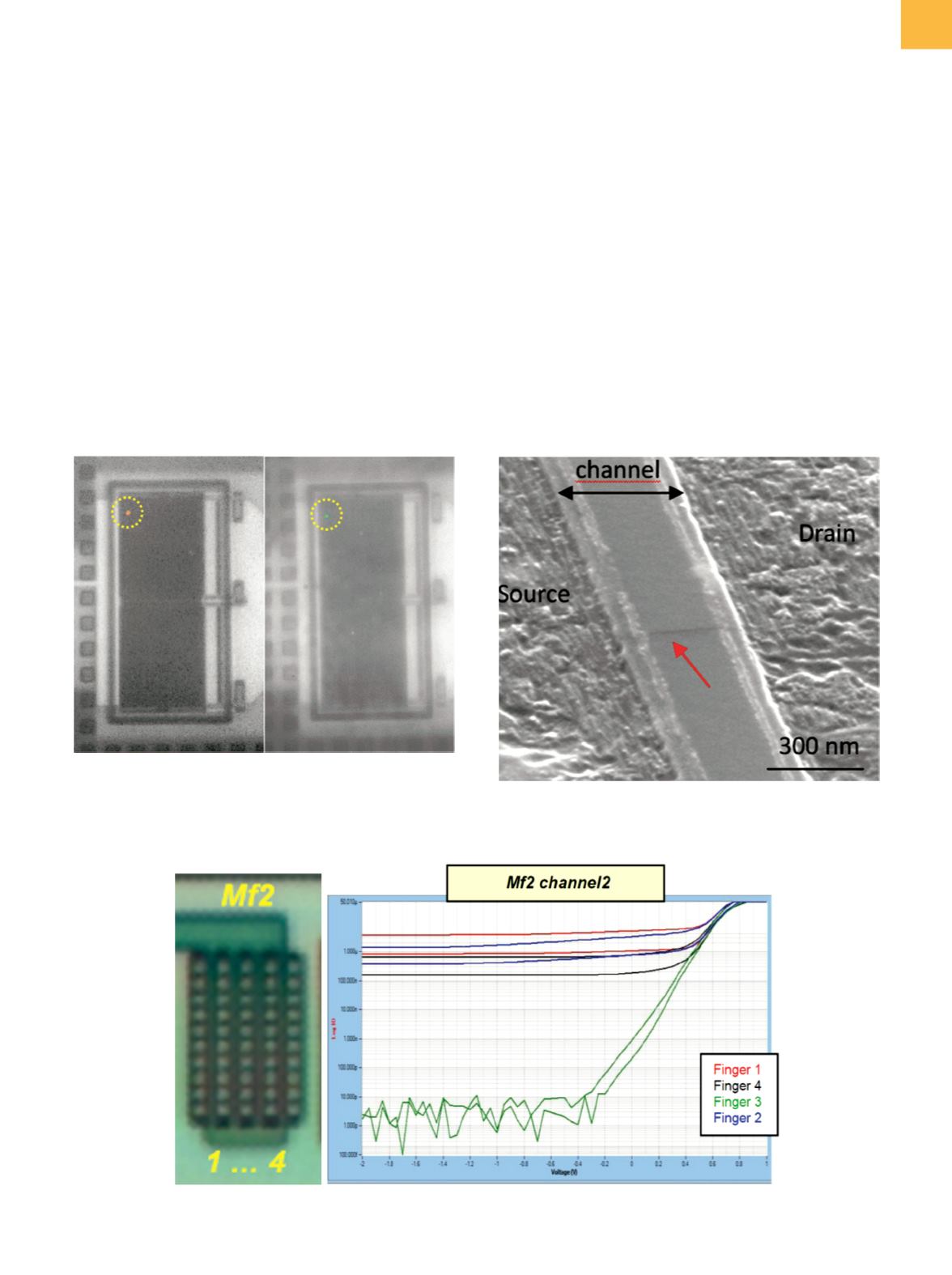

Emission localization. (a) Si-CCD camera (>2 V). (b)

InGaAs-CCD camera (>1.6 V)

Fig. 4

AFP measurement on NMOS in case 2

Fig. 5

Tilted SEM image at silicon active area level with PVC

revealing abnormal dark line in channel region

the leakiest patterns, and the defect can extend further

than the TLS/photoemission analysis.

PHYSICAL INVESTIGATIONS

PASSIVE VOLTAGE CONTRAST AT CONTACT LEVEL

Based on the electrical FA findings obtained in case

1, a step-by-step deprocessing was performed to inspect

the metal layers; no anomaly was observed. At contact/

ILD0 level, passive voltage contrast (PVC) was executed

using SEM, confirming that the NMOS polysilicon gate

was properly insulated from the active area. Because the

metal layer and polysilicon gate were not involved in the

NMOS device leakage, it is most likely that a defect at the

silicon level was responsible for the failure.

SILICON ACTIVE AREA SEM INSPECTION

AND PVC

Deprocessing was done by removing the polysilicon

and gate oxide layers to expose active silicon for SEM

inspection. No silicon damage (indicative of ESDdamage)

was observed, and no wafer fab defect (such as micro-

masking or a silicon topography issue) was identified.

Low-acceleration-voltage PVC was performed to provide

different contrast imaging between differently doped

regions.

[7]

A narrow, straight dark linewas observed at the

NMOS channel area. This hairline passed across all the

NMOS channels, and its position and configuration (paral-

lel to one side of the device structure) exactlymatched the

OBIRCH signature (Fig. 5). In the PVC images, the

n

-type

region is darker than the

p

-type area; the observed dark