edfas.org

edfas.org

5

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 18 NO. 1

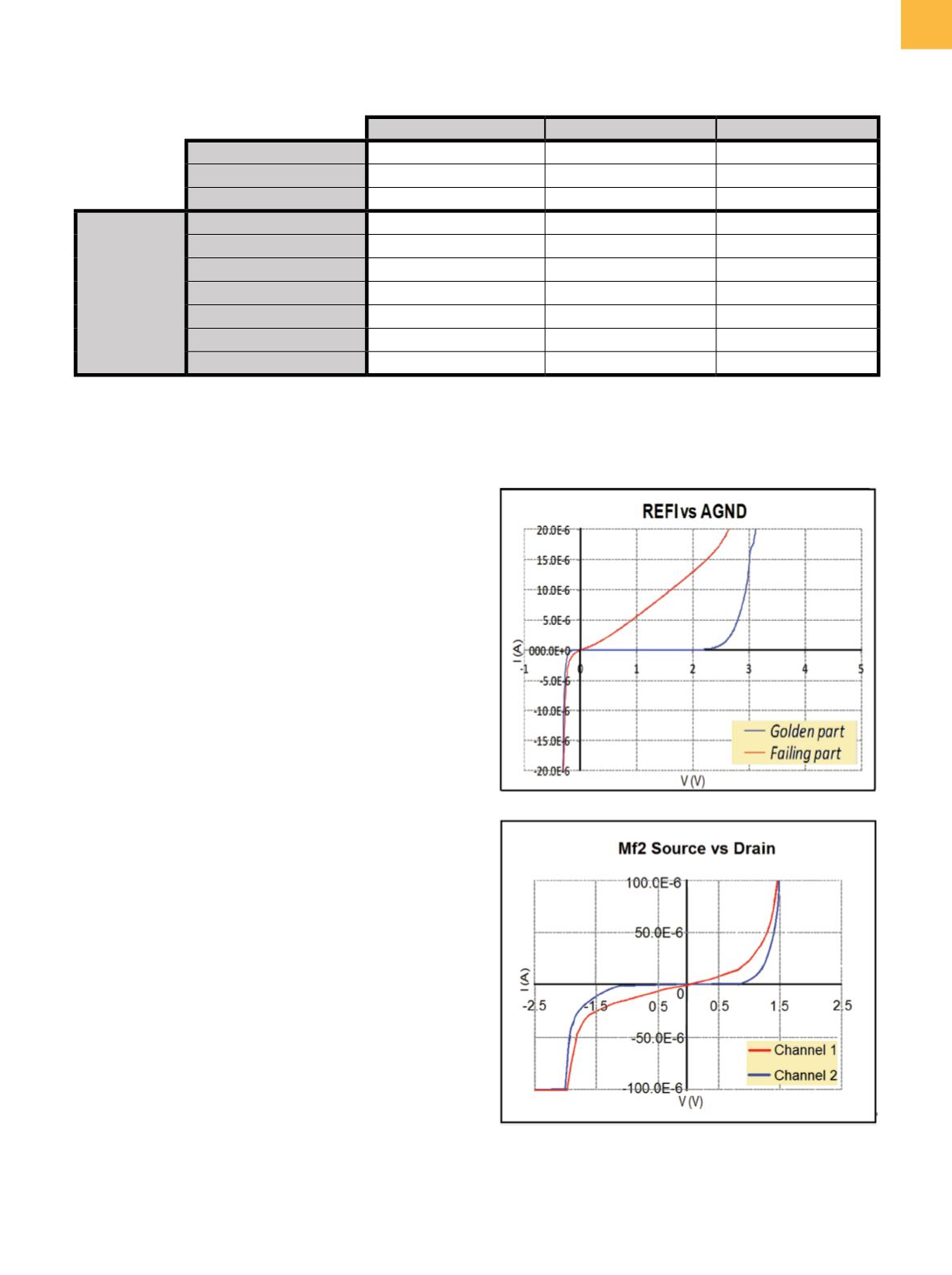

Table 1 Summary of investigations performed on the various products studied

Case 1

Case 2

Case 3

Failure mode

Parametric leakage

Electrical functional

Parametric leakage

Defect signature

Pipeline defect

Pipeline defect

Silicon dislocation

Impacted device type

NMOS

NMOS

NMOS

FA

techniques

TLS

X

X

…

Photoemission

X

…

X

AFP

…

X

…

PVC

X

…

…

Silicon delineation etch

X

X

…

SCM/SMM

…

X

X

Planar TEM

…

X

X

Fig. 1

(a) Parametric leakage characteristic of case 1. (b)

Functional failure. Leakage found bymicroprobing on

failing Mf2 NMOS device in case 2

(a)

(b)

(ESD) structures and single embedded analog transistors

inside a block circuit. The commonality in the three cases

is that the defective device type is always the same: an

NMOS structure.

All the products presented failed at ambient tem-

perature. In case 1, the failurewas observed between two

external pins, REFI and GND, with a leakage of approxi-

mately 2.6 µA at 2 V, compared to a few nanoamps on a

“good” part (Fig. 1a). In case 2, the failure was due to an

offset of 30 mV on the current-sensing circuit of channel

2, generating a functional failure. Microprobing analysis

demonstrated that the failure was due to a drain-source

leakage of the Mf2 (used in the current-measuring chain)

NMOS transistor within the output comparator circuit (Fig.

1b). Based on those results, case 1 was opened from the

backside, and the silicon substrate was thinned.

Thermal laser stimulation was carried out by apply-

ing 1 V between REFI and GND. In this case, the position

of the optical beam induced resistance change (OBIRCH)

spot was located within the ESD structure of the pad and

especially in a specific area of the NMOS transistor (Fig.

2a). TLSwas applied fromthe frontside in case 2, between

the source and drain of this NMOS (Mf2 transistor). The

OBIRCH signature was located on one of the four NMOS

fingers (Fig. 2b). Inboth cases, theOBIRCHsignatureswere

located on the NMOS transistor.

COMPARATIVE STUDY: EMMI/

OBIRCH/InGaAs CAMERA

Anexperimental studywas done in case 1. Leakagewas

initially detected by using TLS (1 V/7 µA/integration time

= 10 s). The aimof this study was to understandwhat type

of defect canbe detectedby the cameras and todetermine

the detection threshold of silicon charge coupled device

(Si-CCD) or InGaAs cameras. The voltage/current was then

increased until the camera could detect the emission of

photons (Table 2). For a voltage below 2 V, the integration