edfas.org

edfas.org

19

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 18 NO. 1

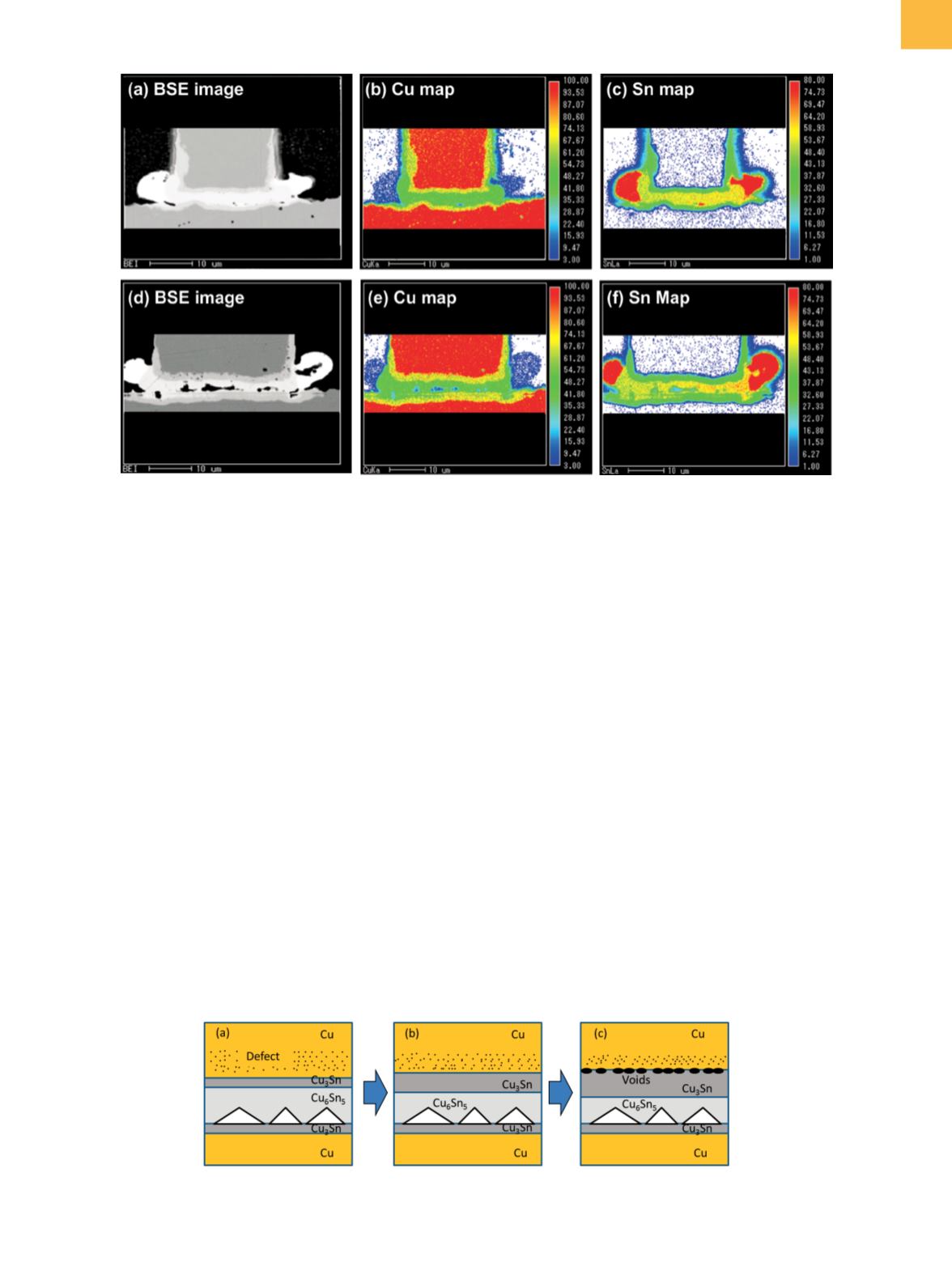

Void formationbasedon this gas exhaust phenomenon

is illustrated in Fig. 8.

A copper pillar

is formed bymicroplat-

ing with a certain aspect ratio, whereas

the

copper

trace

on the substrate is formed from

dense electrolytic copper

foil

. V

olatile

constituents

in

the

copper pillar

are released

as gas

during the TCT

by

interface reaction with the solder

.

SUMMARY

The authors used 3-D SEM analysis to investigate the

flip-chipbump interconnectionof anAP taken froma com-

mercial tablet PC. The analysis technology is based on the

repetition of FIB etching and SEM image capture. Three-

dimensional views were reconstructed from 240 SEM

images that were taken after repeated FIB etching at 200

nm intervals. The authors believe the interconnection to

be a copper pillar with a solder cap connected to a copper

trace on the substrate by thermal compression bonding

with a preapplied underfill. Our analysis showed that

the interconnection joint in the AP as received included

filler entrapment and many voids. With this method, the

generation of a number of voids was clearly observed at

the interface of the pillar copper and the IMC after 1000

cycles of TCT between

-

55 and 125 °C.

REFERENCES

1. M. Lee et al.: “Study of Interconnection Process for

Fine Pitch Flip Chip,”

Proc. 59th Electron. Compon.

Technol. Conf. (ECTC),

2009, pp. 720-23.

2. M. Ritter and P.A. Midgley: “A Practical Approach to

Test the Scope of FIB-SEM3DReconstruction,”

J. Phys.

Conf. Ser.,

2010,

241,

p. 012081.

3. Y. Orii et al.: “Micro Structure Observation and

Reliability Behavior of Peripheral Flip Chip Inter

connections with Solder-Capped Cu Pillar Bumps,”

Trans. Jpn. Inst. Electron. Packag.,

2011,

4

(1), pp. 73-86.

Fig. 7

EPMA mapping of solder joint on flip-chip. (a) to (c) Before TCT. (d) to (f) After TCT. BSE, backscattered electron

Fig. 8

Mechanism of void formation in the system of gas exhaust model in solid-phase diffusion. (a) Before TCT. (b) Slight growth

in Cu

3

Sn. (c) Void formation by accumulation of defects