edfas.org

edfas.org

15

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 18 NO. 1

mechanical polishing is shown in Fig. 1. It seems that the

copper pillar was bonded to the copper wiring on the sub-

strate by TCB using a preapplied underfill. Figure 2 shows

higher-magnification images taken by SEM. An entrapped

filler particle from the preapplied underfill is visible in the

solder joint area.

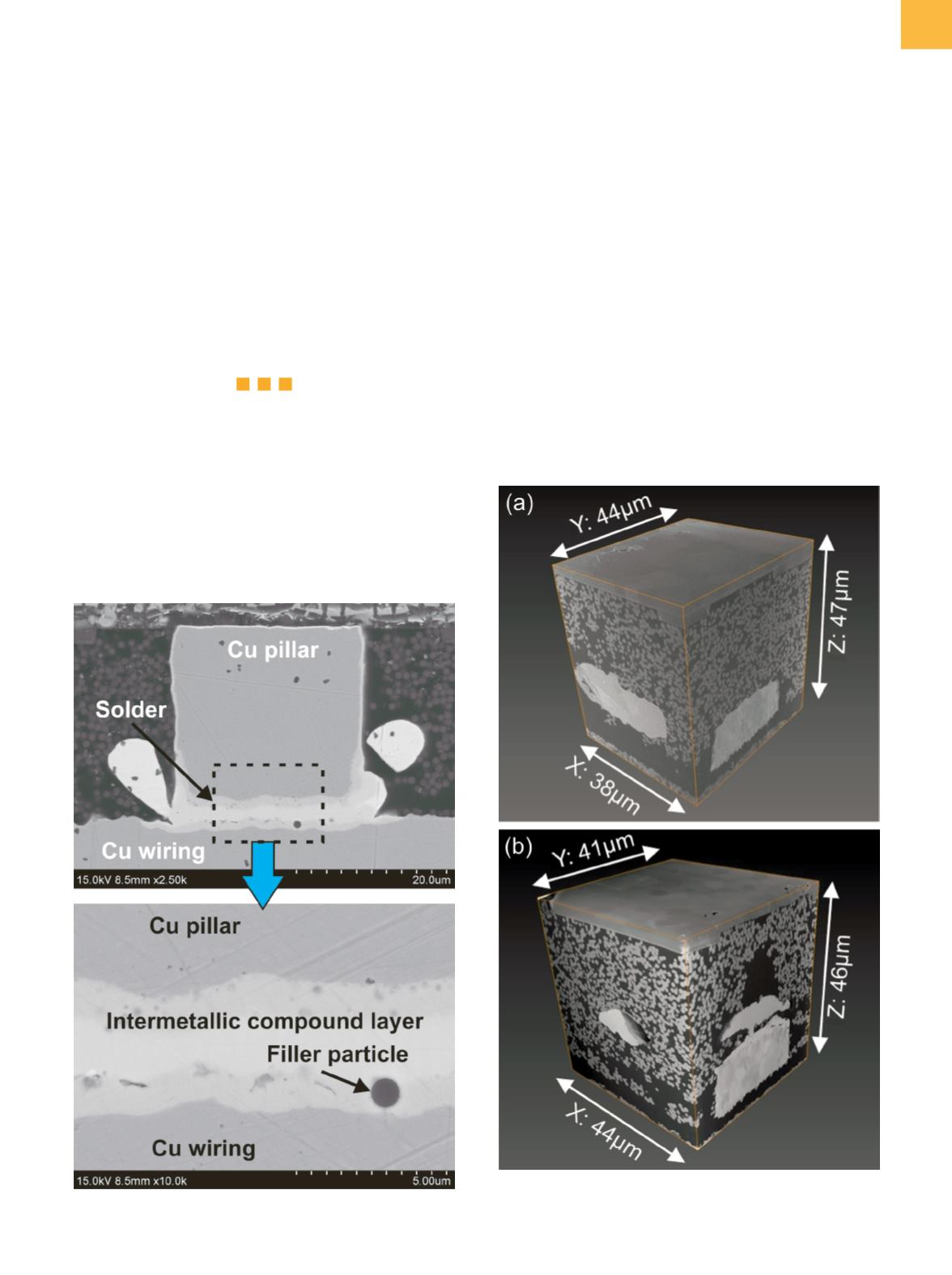

Fig. 2

Cross-sectional SEM images of the flip-chip joint

Fig. 3

Three-dimensional reconstructed images of the flip-

chip joint. (a) Before TCT. (b) After TCT

“THE USE OF COPPER PILLAR WITH A

SOLDER CAP HAS THE ADVANTAGE OF

GANG FINE-PITCH BUMPING BY WAFER

PLATING. INCREASES IN THE NUMBER

OF BUMPS, NARROWING OF PITCH, AND

COST PRESSURES HAVE DRIVEN THE

ADOPTION OF COPPER PILLAR/SOLDER

CAP BUMPING IN HIGH-PERFORMANCE

MOBILE DEVICES. ”

3-D TOMOGRAPHIC RECONSTRUCTION

Figure 3 shows 3-D reconstructed

images

of

the

joint

before

and

after

TCT

. The volume of the reconstructed

space of the joint before TCT is

38

×

44

×

47

μm

3

, and

the volume after TCT is

44

×

41

×

46

μm

3

. Tomographic

images of the

XZ

- and

YZ

-planes of the bump center are

shown in Fig. 4.

The

XY

-plane is parallel to the substrate plane. The

X

-axis is parallel to the copper trace on the substrate, and

the

Y

-axis is perpendicular to it

. The authors observed large

voids,

shown

in Fig. 4(a) and (b) as “Voids (A).” The authors

believe these were generated by solder shrinkage.

[3]

The authors subjected another sample of the same

package to the previously mentioned TCT and then per-

formed 3-D SEM analysis of the solder joint. Another

type of void at the interface of the copper pillar and the