edfas.org

edfas.org

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 18 NO. 1

16

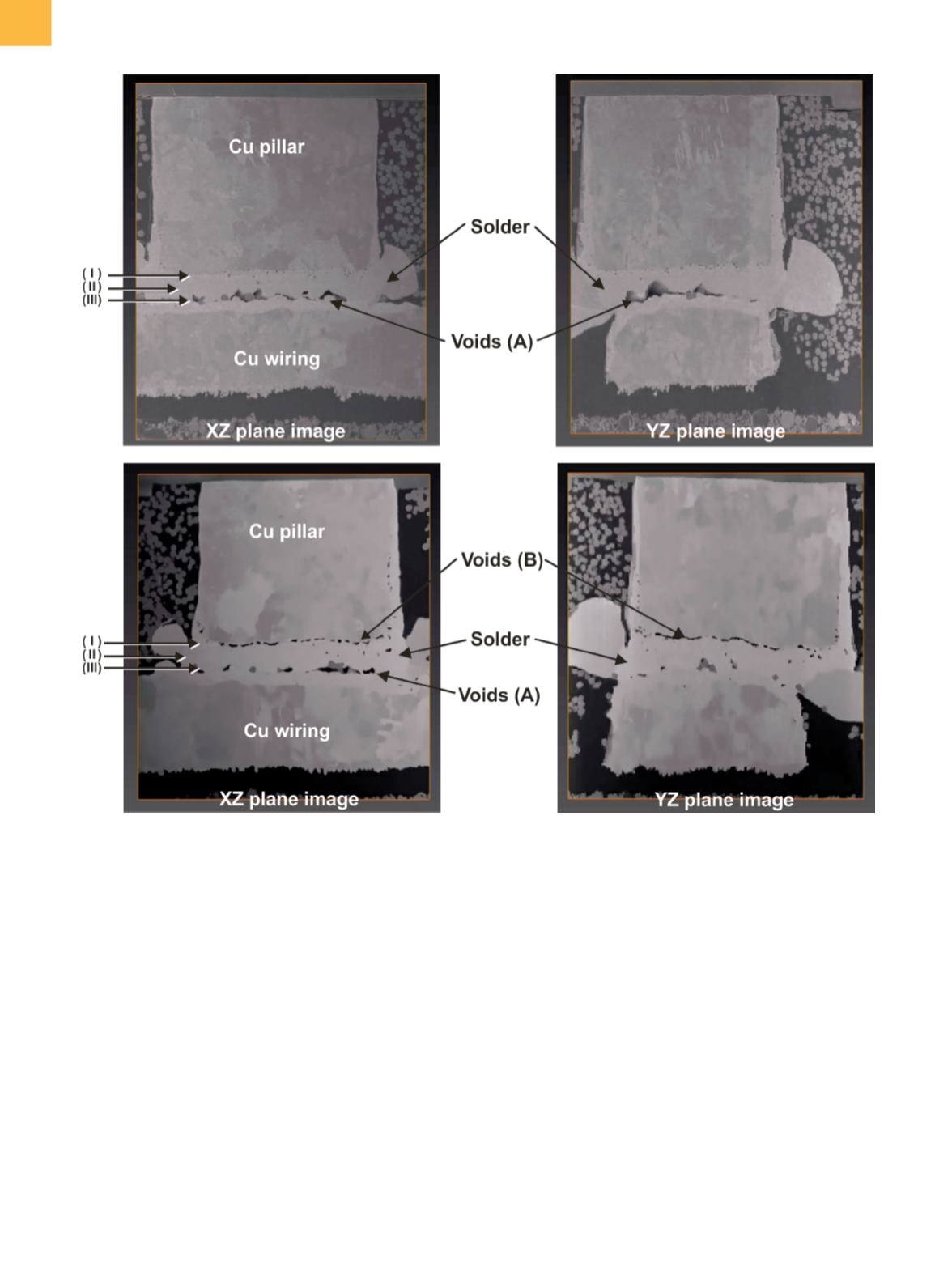

intermetallic compound (IMC) was clearly visible. These

are indicated as “Voids (B)” in Fig. 4(b).

ANALYSIS OF

XY

-PLANE SLICES

Figure 5 shows

XY

-plane t

omographic images of the

solder joints of the packages without TCT (Fig. 5a to c)

and with TCT (Fig. 5d to f). The images were extracted at

three different

Z

-heights:

• Figures 5(a) and (d), at level I (shown by arrow I in Fig.

4), are slice views of the copper pillar and IMC interface.

• Figures 5(b) and (e), at level II (shown by arrow II in Fig.

4), are slice views of the IMC layer.

• Figures 5(c) and (f), at level III (shown by arrow III in Fig.

4), are slice views at the level of the shrinkage voids.

Comparison of the two level-I views (Fig. 5a and d)

shows that the copper pillar and IMC interface changed

significantly with TCT treatment: although only small

voids are observed prior to TCT, numerous large voids

appear after TCT. At level II, v

ery

few voids

were detected

in

the

IMC

layer either before or after TCT

. At level III,

numerous shrinkage voids and entrapped filler particles

from the preapplied underfill are observed. In addition,

the authors were able to observe the 3-D

distribution

of

filler

in the underfill, as well as

gaps between the copper

pillar and the adhesive

.

(continued on page 18)

Fig. 4

Tomographic images of the

XZ

- and

YZ

-planes in the center of the copper pillar. (a) Before TCT. (b) After TCT (

–

55 °C/125 °C,

30 min/30 min, 1000 cycles)

(a)

(b)