edfas.org

edfas.org

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 18 NO. 1

18

DISCUSSION OF VOID FORMATION

MECHANISM

The mechanism

of

void

formation

at

the

interface

between the

copper pillar and

IMC

layer

that occurs during

TCT is discussed below

.

KIRKENDALL EFFECT

The Kirkendall effect, which describes the forma-

tion of voids at the interface of different metals due

to differences in the metals’ thermal diffusivity, is well

known.

[3,4]

In a copper/tin system, as shown in Fig. 6,

a Cu

3

Sn IMC layer can easily grow, which creates the

Kirkendall effect. The EPMA mapping results of the IMC

layer in the authors’ system are shown in Fig. 7. Because

there is not much growth of the Cu

3

Sn layer, it does not

appear that the large-volume voids shown in Fig. 5(d) were

formed by the Kirkendall effect. This is supported by the

fact that no such voids were observed at the interface of

the substrate copper and the IMC.

GAS EXHAUST PHENOMENON AND SOLID-

PHASE DIFFUSION

Studies have shown that volatile

constituents

inside a

plated

copper

film

can move

during soldering processes,

which can lead to void

formation

in

the

solder.

[5]

3-D ANALYSIS OF A COPPER FLIP-CHIP INTERCONNECTION

(continued from page 16)

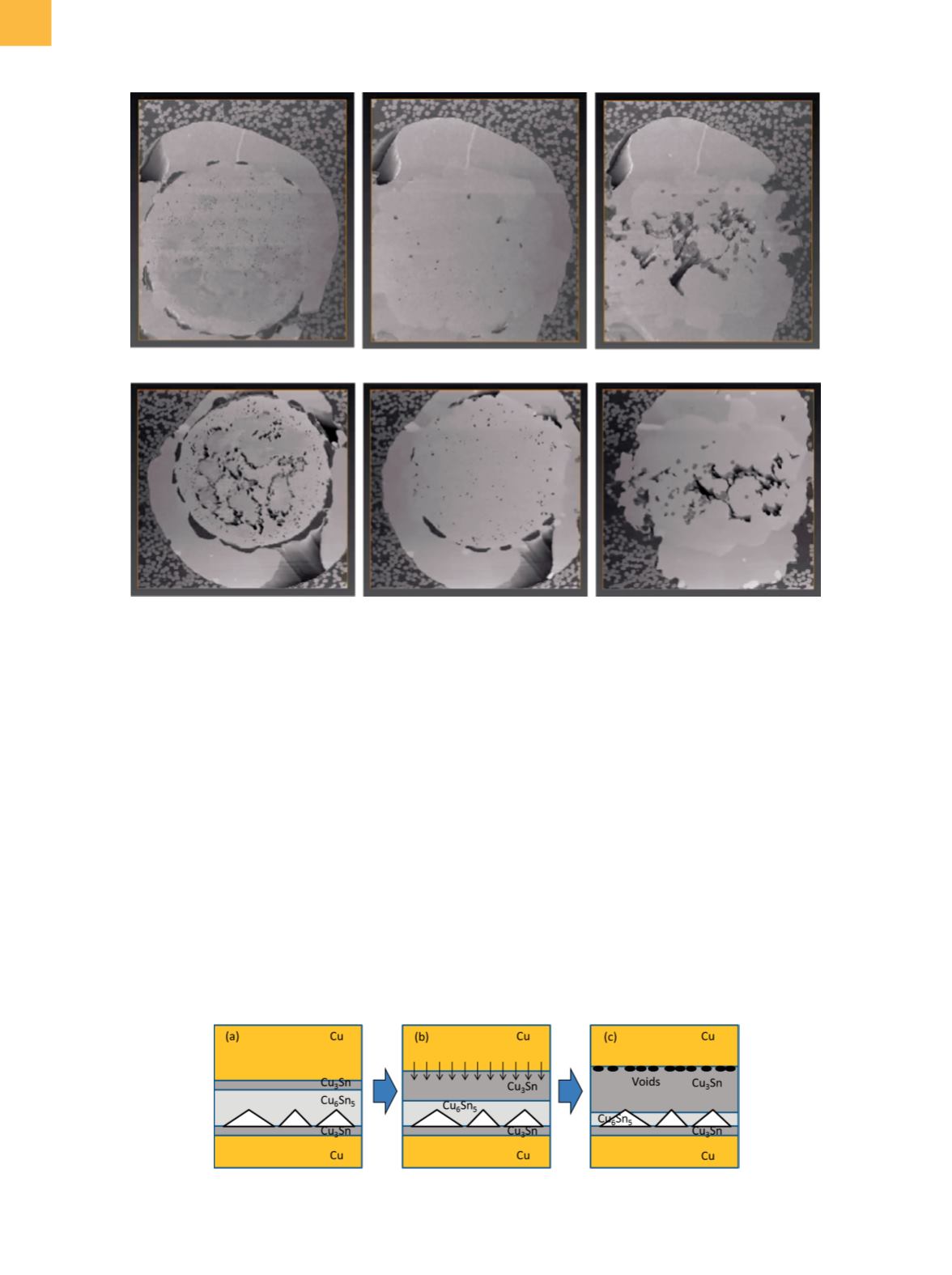

Fig. 5

Tomographic images in the

XY

-plane of the interface between copper pillar and IMC layer. (a) to (c) Before TCT.

(d) to (f) After TCT

Fig. 6

Mechanism of void formation in the system of copper diffusion model. (a) Before TCT. (b) Growth of Cu

3

Sn. (c) Kirkendall

voids formation

(a)

Slice at Interface (I)

(d)

Slice at Interface (I)

(b)

Slice at IMC layer (II)

(e)

Slice at IMC layer (II)

(c)

Slide at shrinkage void (III)

(f)

Slide at shrinkage void (III)