edfas.org

edfas.org

25

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 18 NO. 1

(continued on page 28)

Instances of failures in layers below the surface, allowing

electromigration and eventually resulting in interlayer

shorts, are well documented. Often these failures can

occur while the top metal layers and wire bond are unaf-

fected.

[3]

They are difficult to detect and analyze. A team

approach, involving fab, assembly, and reliability engi-

neers, must focus on the development of pad structures

that not only can achieve electrical design requirements

but are robust enough to withstand manufacturing and

reliability.

CONCLUSION

Wire bonding continues to be the lowest-cost, highest-

reliability, most flexible semiconductor interconnection

method. It continues to reinvent itself; as new demands

are understood, machine, wire, tool, and end users come

together to find solutions that enable successful imple-

mentation of the new requirements. Each newgeneration

of devices has required increased capabilities for both

manufacturing and metrology. Wire bonding has met

these challenges and added the capabilities necessary

for its continued growth as the leading semiconductor

interconnection method.

REFERENCES

1. M. Sheaffer, L. Levine, and B. Schlain: “Optimizing the Wire Bonding

ProcessforCopperBallBondingUsingClassicExperimentalDesigns,”

Proc. Int. Electron. Manuf. Technol.

(IEMT),

Sept. 1986, pp. 103-08.

(b)

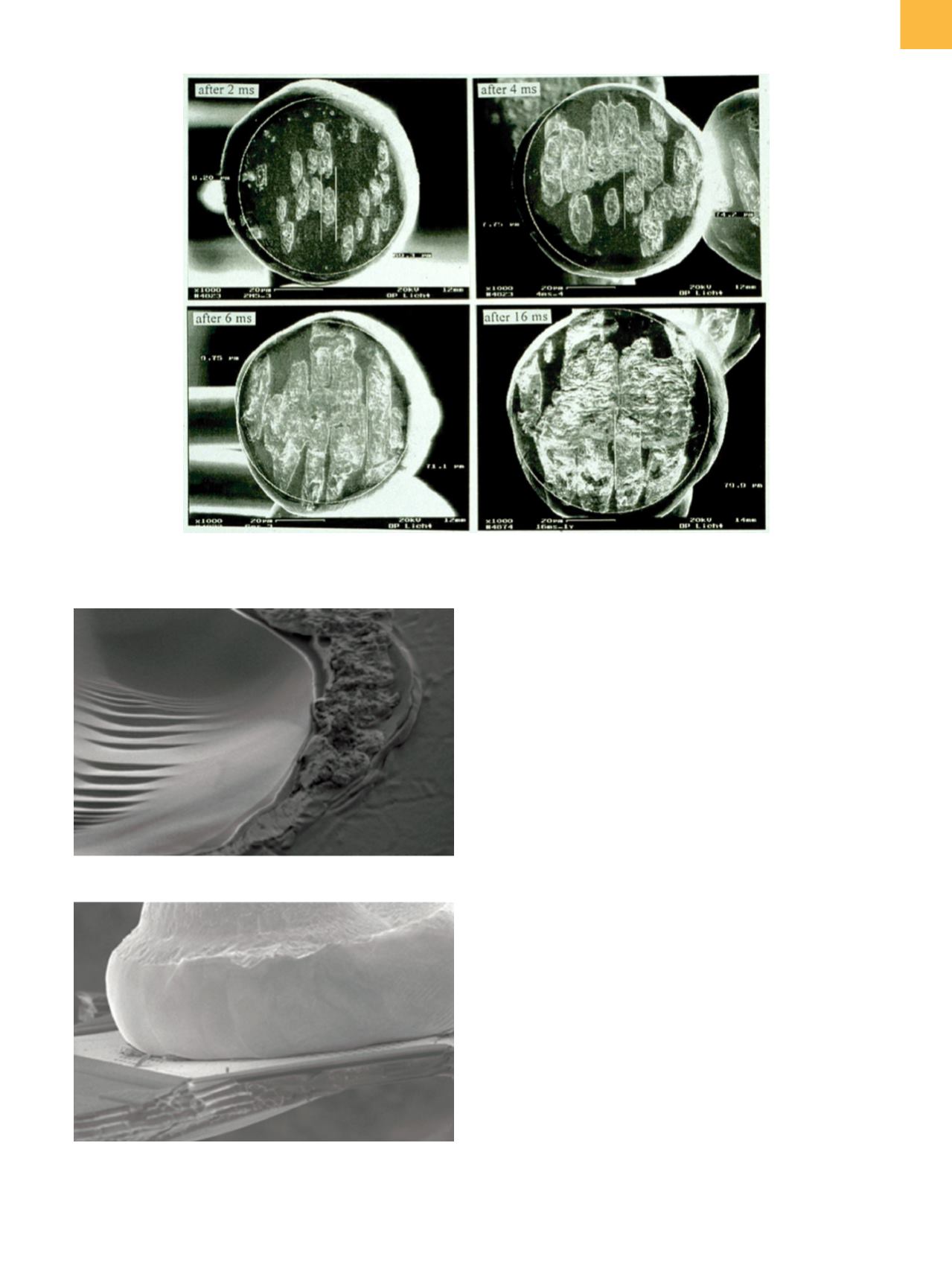

Fig. 4

Thermosonic (120 kHz) ball etch-off patterns showing weld-growth formation. Courtesy of ESEC (now BESI North America)

Fig. 5

(a) Fracture of silicon die below bond. (b) Fracture of

multilevel bond pad

(a)