edfas.org

edfas.org

31

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 18 NO. 1

DELAYERING/DEPROCESSING

Delayering of integrated circuit (IC) devices is an

important tool for semiconductor failure analysis, reverse

engineering, and circuit edit activities.

[4]

Once a defect

has been localized, it is necessary to isolate, inspect,

and perform failure analysis. One method to enable this

is to remove layer after layer until the defect is exposed.

Traditionally, thiswas performedbymechanical polishing,

followed by observation in either an optical or electron

microscope. While this method can provide reproducible

results in older process nodes over large areas (which

is important for reverse engineering), it is neither site-

specific nor planar. In addition, this method does not

have predictable end-pointing, and the functionality of

the entire chip is lost due to the destructive nature of the

polishing.

The FIB offers the means to retain chip functionality

while removing only localized regions during delayer-

ing. This is a great advantage, allowing further analysis

(voltage contrast, defect analysis, electrical probing, etc.)

or circuit edit to be performed when the layer of interest

has been reached. However, it is no easy task to delayer

modern IC devices in the FIB, due to the large number of

different layers (with vastly differingmilling rates) that are

present with varying thicknesses andmechanical proper-

ties. The divergent milling rates of the different materials

present result in nonplanar delayering, often with many

layers visible at one time.

A new beam chemistry, Dx,

[4]

has been developed to

deliver planar delayering. It can mill both dielectric and

mixed-field regions uniformly. In addition to better end

results, the process is simpler because it is continuous,

without the need to stop the milling to change gas chem-

istries when different layers are encountered. In addition,

the reduced enhancement of themilling improves control-

lability, which is an important considerationwhen dealing

with sub-100-nm-thick layers.

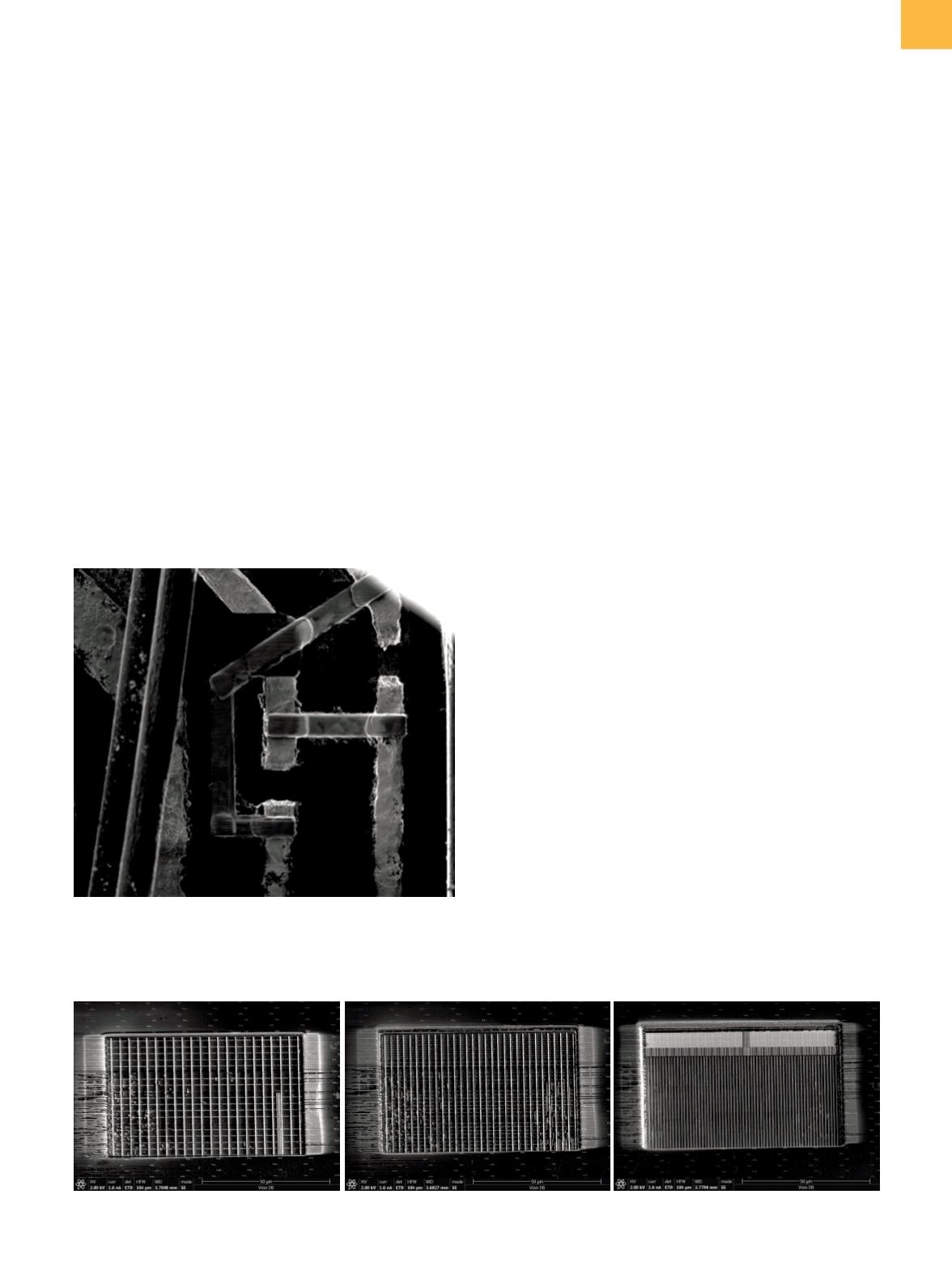

An example of the delayering possibilities when Dx

is combined with the xenon beam can be found in Fig. 3.

Here, a 22 nm device has been delayered from the front

side. The images show the excellent planarity achieved

by delayering through a stack of six copper metal layers

andSiO

2

and low-k dielectrics using the significantly larger

beam currents than are available on the gallium FIB for

delayering. Despite these larger currents, no degradation

of the planarity in the trench is observed.

The combination of delayering with Dx and the xenon

PFIB produces a more representative surface, which

is important for (in situ) nanoprobing experiments.

Implantation from the xenon ion species is lower than

gallium, but gallium, being a metal, produces some

conductive redeposit on the surface. This does not occur

when the xenon beam is used, and amore pristine surface

results. This allows proper electrical characterization to

be carried out through nanoprobing.

SITE-SPECIFIC FAILURE ANALYSIS

Today, 3-D system-in-package integration together

with advanced interconnect technologies based on TSVs,

Fig. 2

Package-level edit with xenon PFIB consisting of two

copper trace cuts and two platinumconnections while

preserving electrical functionality with insulator

deposition

Fig. 3

100

×

100 µm trench exposing (left to right) M9, M7, and M5 on a 22 nm device