edfas.org

edfas.org

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 18 NO. 1

34

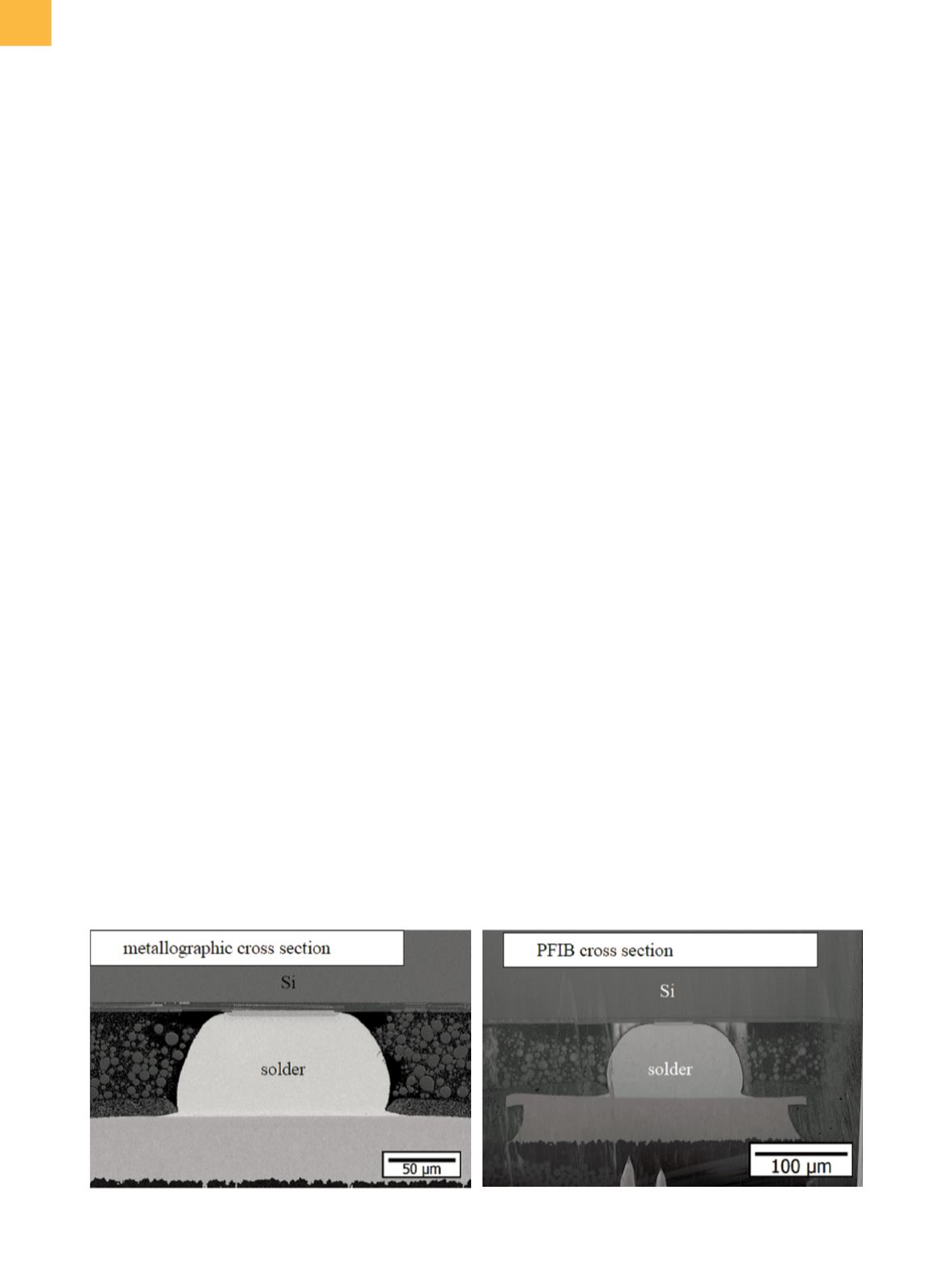

High-current PFIB milling offers a new opportunity to

cut through thewhole silicondie and solder bump contact

without any need for mechanical grinding procedures.

In this case, the solder joint contacts have a diameter

of 150 μm, which is a typical dimension. As a first step,

rapid cross sectioningwas done at the highest achievable

xenon beamcurrent of 1.3 μA. The coarse PFIBmilling of a

500-μm-long and 1-mm-deep box takes

∼

10 h of milling

time. Thefinal polishingwas doneby rockingbeammilling

at ±8° sample tilt by using a 1.3 μA xenon beam.

Figure 6 compares the PFIB-sectioned

[6]

solder joint

contact to a standard metallographic cross section.

The cross-sectional surface using PFIB preparation has

a remarkably improved quality; nearly no preparation

artifacts, for example, curtaining, are detectable. The

microstructural investigations show interface reactions

between solder joint contact and underbump metalliza-

tion. The underbump metallization shows the typical

depletion zone of the nickel-phosphorus (Ni

3

P layer) that

occurs because of the interdiffusion of nickel into the tin

solder material and the nickel-tin IMC formation at this

interface, respectively.

IN SITU ELECTRICAL FAULT ISOLATION

Transistor and interconnect-level characterization

plays a critical role during semiconductor process devel-

opment, for which samples are historically preparedusing

wet/dry etch, mechanical polishing, or conventional FIB

techniques. Using PFIB-based deprocessing techniques,

it is now possible to prepare advanced-technology-node

samples for electrical fault isolation (EFI) over large

areas (hundreds of micrometers) with higher yield and

repeatability. The EFI samples are further analyzed using

SEM image-based inspection and analysis, SEM-based

nanoprobing, or atomic force probing (AFP). Historically,

samples were polished on mechanical polishers by a

sample-preparation expert, followed by inspection on

an optical microscope or SEM to ensure that the desired

layers were reached. Then, the samples were moved to

an SEM- or AFP-based prober for further analysis by a

different set of probing experts. These two steps were

repeated for a few cycles as long as further deprocessing

was possible or until the fault was isolated. There was

a long wait time between each stage in the queue from

sample submission to final results, due to tool and opera-

tor availability, resulting in lower yields due to required

operator skills and tool capabilities.

Recent advances have enabled the integration of

sample-preparation and fault-isolation capabilities inside

a DualBeam PFIB system, thereby creating a single-tool,

single-operator solution that takes the sample from

delayering through high-resolution imaging and SEM-

based nanoprobingwithout sample transfers, wait times,

or multiple experts. This in situ preparation and analysis

approach provides faster results at a much higher yield

and in a more predictable manner. PFIB-based depro-

cessing, in combination with SEM-based imaging and

nanoprobing for localizing electrical faults, has been

performed on samples at the 10 nm node with transistor

I-V characterization, electronbeam induced current (EBIC)

on diffusion, and electron beamabsorbed current (EBAC)-

based analysis on a copper, low-k dielectric interconnect

stack. High-resolution imaging with low-beam-energy

SEM down to 350 eV combined with low-drift probes

enables easier setup resulting in analysis, as shown in

Fig. 7(a) and (b).

With material-removal rates 20 to 100 times greater

than gallium liquidmetal ion source FIB, PFIB is becoming

an essential tool for failure analysis of larger structures

created by new advanced packaging processes. Failure

analysis and fab support labs can also take advantage

of the DualBeam PFIB’s targeted chemistries for physical

Fig. 6

PFIB-sectioned solder joint compared to metallographic cross section