edfas.org

edfas.org

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 18 NO. 1

32

through-encapsulant vias, and microbumps are consid-

ered some of the most promising enabling technologies

for “More than Moore” solutions.

[5]

These technologies

involve vertical dice stacking or chip embedding with

high-density interconnects and are based on combina-

tions of process steps that come from formerly strictly

separated technology areas. Thus, there is an increasing

need to understand a large number of different interface

properties between different interconnects and, with

any encapsulation or lamination materials, to control

and optimize process steps and layer thicknesses and to

avoid any defect formation that potentially could affect

the component’s reliability. This complexity in terms of

design, new materials, and material combinations also

requires the development of newsystem-adequate failure

analysis tools capable of providing information on adhe-

sion mechanisms, interdiffusion, and phase formation

processes, or on electrical short, crack, and void forma-

tion issues. Therefore, there is a demand for metrology,

physical characterization, and failure analysis of a wide

range of 3-D interconnect technologies and relevant pro-

cesses, and also for preparation and analysis techniques

that allow access to buried structures providing physical

information at the nanometer scale within a large field

of view. Depending on the material under investigation,

both the higher current and the higher sputter efficiency

of xenon significantly improve the range of application

fields and/or the analysis throughput. Thismakes thePFIB

a very attractive tool for the analysis of relatively large

interconnect structures without any need for mechanical

preparation steps.

An open TSV interconnect technology has been devel-

oped as an alternative to copper-filled TSVs. The Bosch

etching process, combined with further IC processing

steps, is used to form TSV structures with sidewall isola-

tions and metallization with titanium/TiN, tungsten, and

aluminum. Finally, the TSVs are cappedby a silicondioxide

film and silicon nitride layers. For process optimization

and failure analysis, the sidewall layer structure must be

imaged and measured. Rapid PFIB milling can provide

precise cross sectioning to gain access to specific TSV

areas of interest or to defect siteswithin the TSV structure.

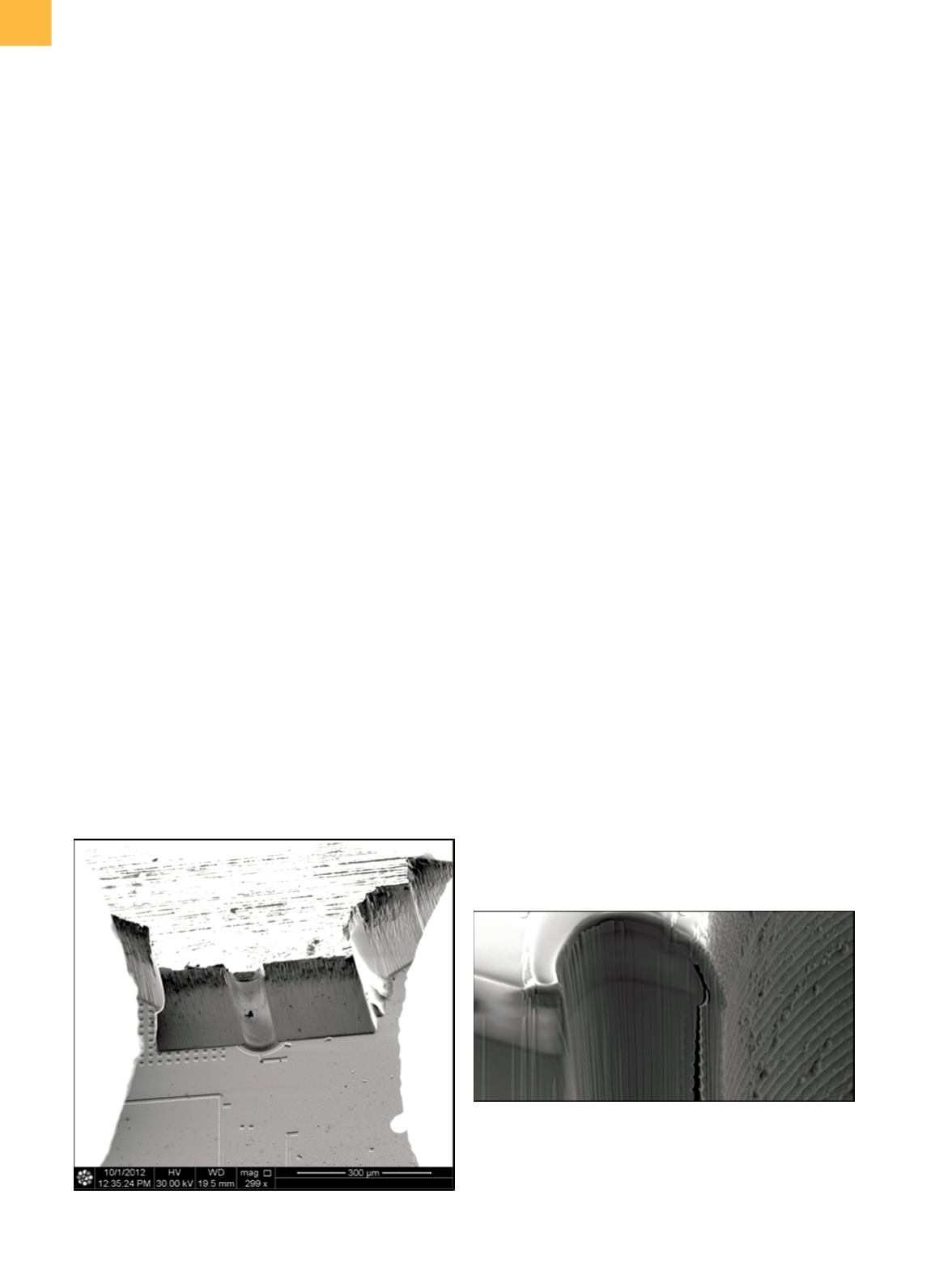

Figure 4 shows anopenTSVwith localizeddelaminated

sidewall layers. To find the root cause, the delaminated

sidewall interface shouldbeanalyzedby scanningelectron

microscope (SEM) and transmission electronmicroscope

imaging. In this case, mechanical grinding was not an

option for rough cross sectioning, because of the high risk

to fully detach the delaminated sidewall layer. Therefore,

rapid PFIB milling with a 1.3 μA xenon beam was applied

to obtain a cross section through the middle of the TSV. A

box of 700

×

300 μm and 500 μm was milled within only

5 h. Then, local sidewall polishing at 70 nA was done at

the upper left of the TSV, followed by SEM imaging of the

delaminated sidewall layer.

DIE-TO-DIE INTERCONNECTS

A fundamental requirement for any 3-D interconnect

scheme is a method for connecting the stacked dice to

each other and/or to any interposers used. Stacking

schemes may use a combination of face-to-face, face-

to-back, and die-to-interposer bonding and could also

involve a direct connection between the dice or include

a redistribution layer added to the front/back of the origi-

nally manufactured die. Whatever the scheme, there are

typically some similar challenges for creating site-specific

sections of the interconnects, in particular, locating the

Fig. 4

Delamination of sidewall in open TSV, milled with PFIB. Source: Ref 2