A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A Y / J U N E

2 0 1 7

2 3

is preferred because it can be easily

controlled using programmed cycles of

the casting machine. Generally, a DiASil

cylinder block is de-molded at about

380°C, which is approximately 100°C

below the alloy solidus temperature

(end of the solidification process). This

de-molding temperature is high enough

to bring about the microstructural and

related mechanical properties chang-

es needed when the casting is subse-

quently quenched in water. Increasing

the de-molding temperature enhances

the casting response to the aging pro-

cess upon water quenching, but could

create the risk of ejecting the casting

from the mold when it is not completely

solid.

Water quenching after de-molding

is typically used to cool castings for eas-

ier handling prior to the next manufac-

turing step, which could include heat

treatment, machining, and inspection.

Subsequent operations are sometimes

carried out in a separate facility requir-

ing transportation of castings. Besides

water, quenching oils, emulsions, and

compressed air can be used to cool the

casting. Choosing the best cooling me-

dium depends on overall process re-

quirements including casting geometry,

residual stress considerations, and sub-

sequent processing steps. Quenching

can also be used to retain some degree

of solid solution resulting fromnonequi-

librium solidification, to prevent the dif-

fusion of alloying elements. This super-

saturated solid solution improves the

precipitation process through artificial

aging. Increasing the quenching rate

and avoiding quenching delays enhanc-

es the aging response. Average casting

quenching cooling rate inwater is about

40°C/s, and is sufficient to observe an

improvement in casting hardness

[1]

. Fig-

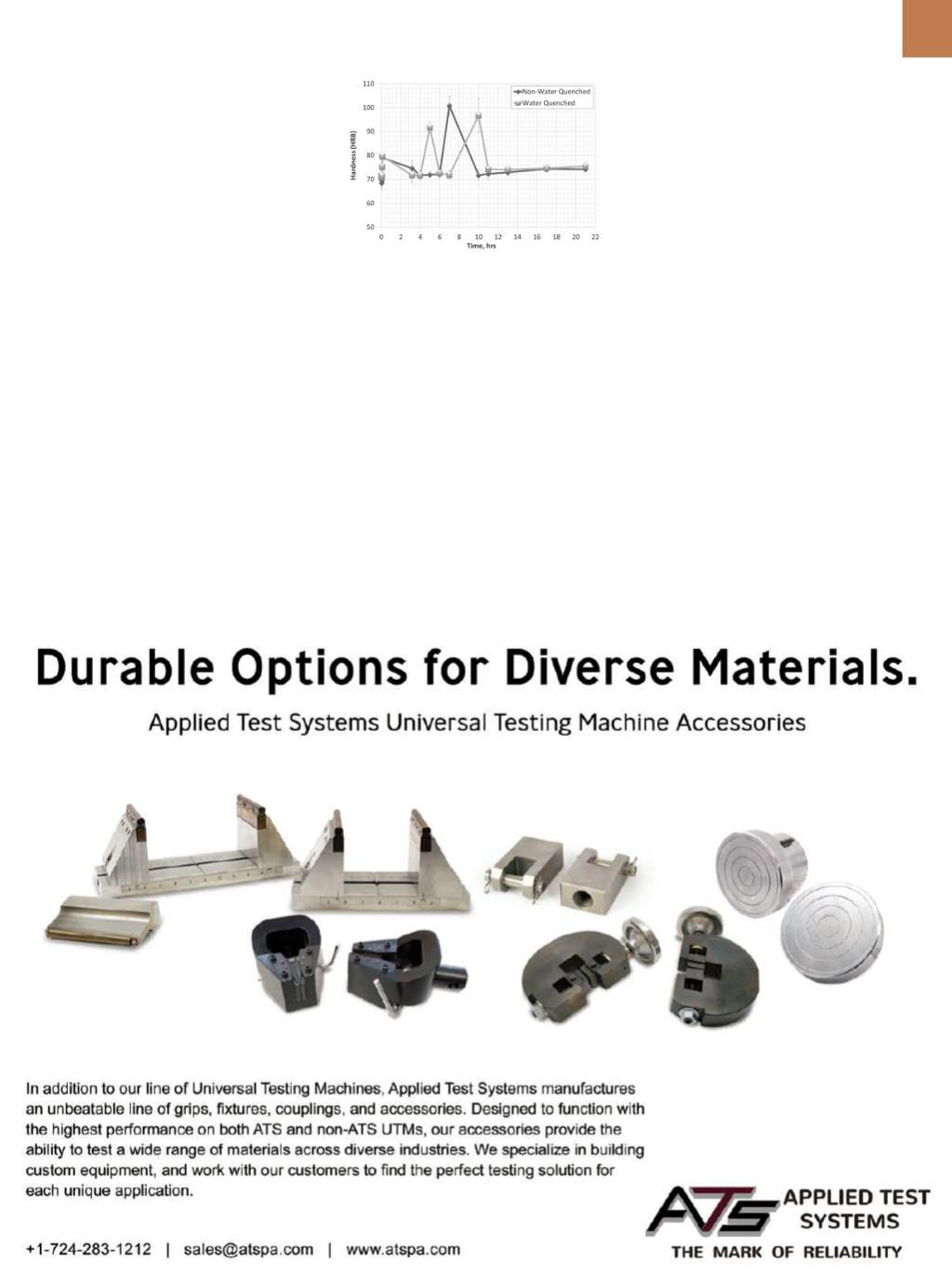

ure 6 shows the effect of water quench-

ing on test casting coupon hardness

for various temper conditions; hard-

ness is increased by an average of up to

5% for water quenched castings.

Effect of time delay between cast-

ing and tempering operations.

The time

a casting is held at room temperature

prior to heat treatment depends on the

specific manufacturing cycle. For ex-

ample, heat treatment done in-house

as a continuous operation enables pre-

cise definition of cycles. For castings

heat treated at a different facility, the

duration of holding castings at room

Fig. 8 —

Variation in macrohardness for the

test casting in the T1 as-cast condition as

a function of natural aging time (days), i.e.,

delay between the completion of casting

process and beginning of T5 temper for

non-water quenched aer casting de-mold-

ing and water quenched aer casting

de-molding

[1]

.