A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y / J U N E 2 0 1 7

2 2

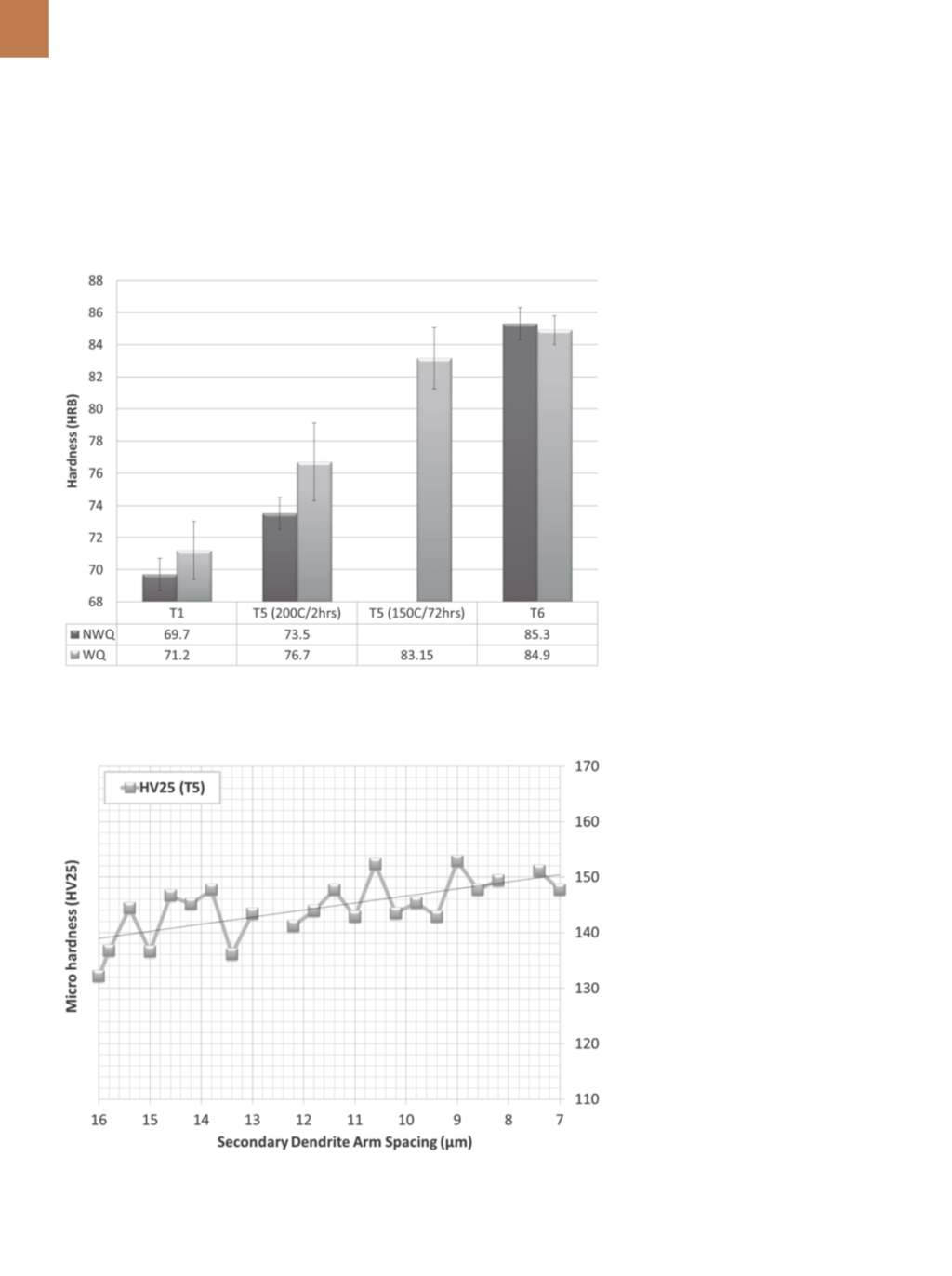

this effect. This process requires addi-

tional equipment with a corresponding

higher manufacturing cost. Even with

reduced heat treatment cycle times,

the T6 temper is more costly than the

T5 temper. Advantages of the T5 temper

include reduced capital equipment cost

due to eliminating the solutionizing

treatment. The lower overall cycle time

of the T5 temper (Fig. 5) reduces man-

ufacturing cost while still achieving the

required engine block hardness.

T5 temper optimization

is being

studied to find ways to increase hard-

ness and reduce processing time. Artifi-

cial aging at 150°C for 72 hours, carried

out after casting, de-molding, and wa-

ter quenching, resulted in a maximum

hardness of approximately 83.1

r

1.9

HRB, while aging at 200°C resulted in a

peak hardness of 76

r

2.4 after 2 hours

[1]

(Fig. 6). Such a hardness range allows

some flexibility to reduce temper du-

ration while maintaining the hardness

required to meet the critical tribologi-

cal characteristics of the cylinder bore

surface

[2]

.

Casting solidification rate.

During

HPDC, die cavity liquid metal filling

time is extremely lengthy, but could be

as short as 50-100 ms

[4]

. Consequently,

accurately determining the alloy so-

lidification rate is difficult and impos-

es technical challenges. This is mainly

due to the inability to collect adequate,

unbiased temperature signals, i.e., sig-

nals that represent true thermal event

history coming from the solidifying

melt with minimum thermal inertia im-

posed by the casting die’s large thermal

mass. Direct placement of thermocou-

ples in the HPDC die cavity is not a reli-

able method, and could result in sensor

damage because the cavity is filled with

superheated metal under high veloci-

ties and pressures. The estimated cast-

ing solidification rate could be as high

as ~103°C/s, but the specific value de-

pends on alloy composition, mold/part

geometry, and process parameters

[5]

.

Studies show that the fine micro-

structures (seconary dendrite arm

spacing, or SDAS, between 5 and 30 m)

achieved in HPDC enable a significant

reduction in heat treatment process-

ing time for T6 as well as T5 tempered

parts. A further increase in T5 temper

hardness is possible via microstruc-

ture refinement. Figure 7 shows the

increase in T5 hardness for samples

with smaller SDAS size: 150 HV25 for

7 m compared with 138 HV25 for

16 m.

Casting de-molding temperature.

Casting de-molding is typically carried

out below the solidus temperature to

ensure that the casting is 100% solid

before ejection from the die. Typical-

ly, an exact temperature is not used in

industrial process control because it is

difficult to determine for cooling rates

seen in the permanent mold casting

process. Instead, the time correspond-

ing to the casting de-molding operation

Fig. 6 —

Casting hardness in the T1, T5, and T6 (510°C/0.5h and artificial aging at 200°C/2h)

conditions. The dierences between water quenched (WQ) and non-water quenched (NWQ)

conditions are statistically significant except for the T6 temper

[1]

.

Fig. 7 —

Increase in microindentation hardness (HV25) as a result of microstructure refinement

for SDAS from 16 to 7 ¦m for the test casting T5 tempered at 150°C for 48 h. These data indicate

that more refined structures oer higher hardness aer tempering

> @

.