A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y / J U N E 2 0 1 7

1 8

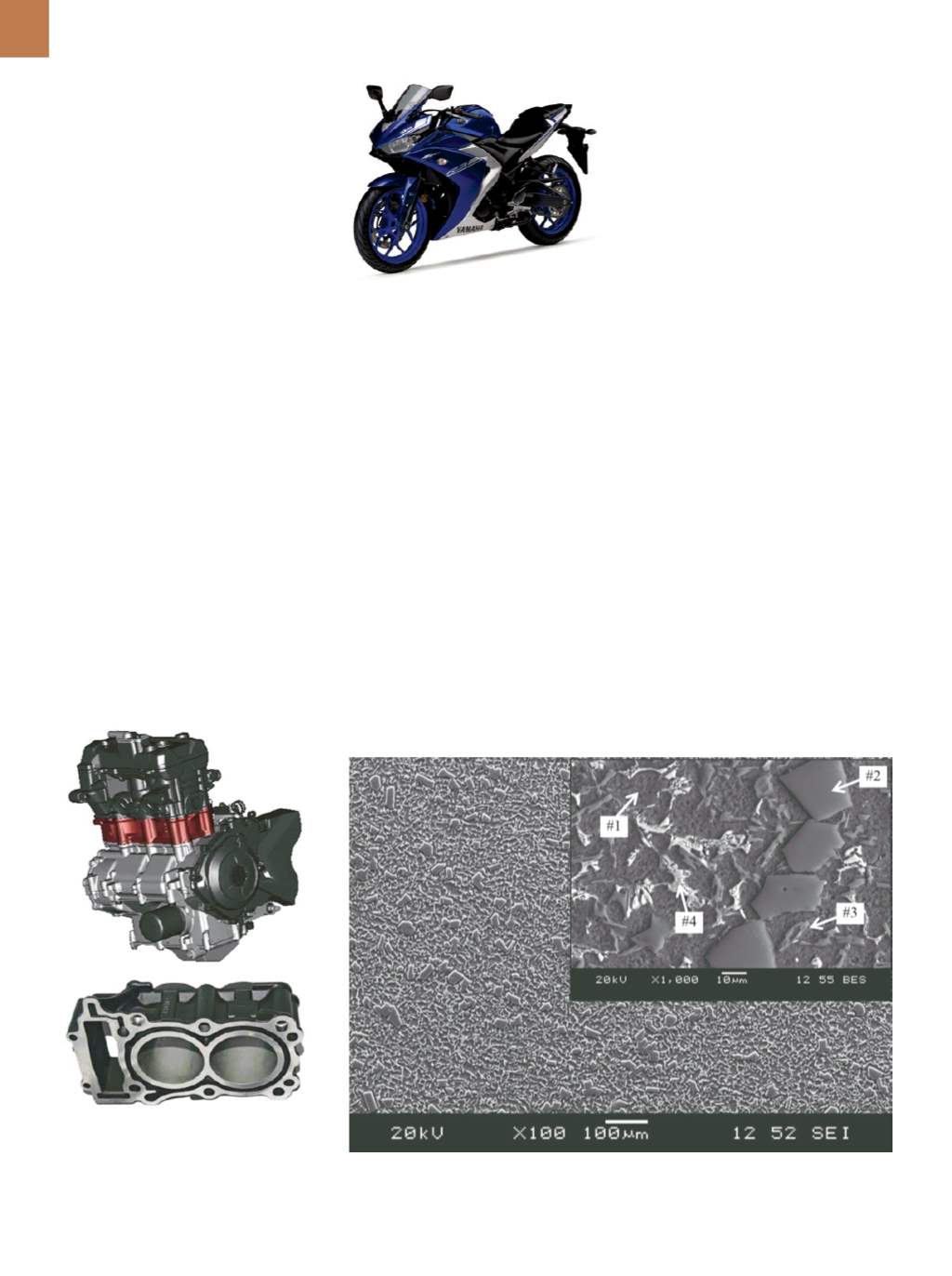

Fig. 1 —

Water-cooled 250 cm

3

motorcycle

cylinder block made of hypereutectic Al-Si

alloy (DiASil) using the HPDC process: (a) as-

sembled engine overview; (b) engine block

casting. Courtesy of Yamaha Motor Co.

L

ightweight Al-Si base alloys are key

engineering materials for use in cast

automotive powertrain appli-

cations due to their combination of

structural and service characteristics.

Specifically, hypereutectic Al-Si alloys

containing >12 wt% Si are materials of

choice for use in applications such as

engine blocks

[1]

. A monolithic (linerless)

engine block design is cost effective

because it eliminates the need to use

press-fit or cast-in cylinder sleeves (het-

erogeneous design), or Cr-Ni base coat-

ing (quasimonolithic design) in which

thermal spray is deposited on the bore

surface

[2]

. The monolithic design is used

in small one-cylinder motorcycles

[3]

,

and more recently for manufactur-

ing two-cylinder, water-cooled engine

blocks (Fig. 1). Such engines meet size

and performance specifications and are

used in mid-size motorcycles yielding

36 hp @ 12,000 rpm from 250 cm

3

dis-

placement (Fig. 2).

Monolithic engine blocks made

of DiASil* (die cast aluminum silicon)

hypereutectic Al-Si alloy (Al, 17%Si,

4.5%Cu, and 0.5%Mg) meet modern

engine requirements including cooling

performance, light weight and com-

pact design, and low manufacturing

cost. Alloy wear resistance and thermal

conductivity are the main factors affect-

ing oil consumption and engine cool-

ing characteristics. Oil consumption

for monolithic blocks measured on a

10,000-km running test at approximate-

ly 7000-9000 rpm is improved by up to

50% compared with that for heteroge-

neous blocks.

The alloy’s tribological properties

are mainly controlled by the primary Si

size, distribution, exposure height from

the aluminum matrix, and overall alloy

hardness

[1]

. Figure 3 shows the repre-

sentative microstructure of an etched

material sample, which removed a rel-

atively soft

D

-Al matrix and resulted in

exposed primary Si, Al-Si eutectic, and

Cu-Mg base phases. The etched surface

closely represents an actual cylinder

bore following honing. After honing,

the primary Si crystals are exposed as

high as 0.5 m. Removal of the metal

matrix exposing primary Si crystals pro-

motes elastohydrodynamic lubrication

(EHL), which is required to withstand

the reciprocal movement of the engine

piston

[2]

.

A monolithic block can be pro-

duced by various techniques includ-

ing sand casting, lost foam, and the

semipermanent process. High pres-

sure die casting (HPDC) offers high

production rates and satisfactory qual-

ity at a competitive price. An HPDC

system used for R&D studies at Can-

metMaterials laboratory is shown in

Fig. 4. In the HPDC process, liquid met-

al is transferred into a shot sleeve from

a holding furnace and injected into the

water-cooled die where it rapidly so-

lidifies under hydraulic pressure. The

actual pressure depends on specific

equipment configurations and could be

as high as 120 MPa, with a melt flow ve-

locity between 30 and 60 m/s (100 and

200 km/h) at the gates

[4]

. When the met-

al temperature drops below the soli-

dus, the casting is ejected from the die

Fig. 2 —

Mid-size motorcycle powered by a

lightweight 250 cm

3

water-cooled two-cylin-

der engine. Courtesy of Yamaha Motor Co.

Fig. 3 —

Hypereutectic Al-Si alloy (DiASil) microstructure aer chemical etching. Inset, because

the

D

-Al matrix (1) was removed, this resulted in exposure of primary Si (2), Al-Si eutectic (3), and

Cu/Mg base phases (4).

a)

b)