A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A Y / J U N E

2 0 1 7

2 9

spectrum, SDDs can typically produce

equivalent if not better data in less

than 10 seconds. This makes sample

inspection much more immediate and

interactive. An added benefit of using

a lower beam current is that in some

SEMs, it can greatly improve imaging

resolution as well.

SEM/EDS DEMONSTRATION

To demonstrate the combined ca-

pabilities of SEM, EDS, and SDD tech-

nology, the author prepared and tested

two glass samples, the results of which

are presented below. The first sample is

a coated glass cover slip meant to be at-

tached as a protective layer over an ex-

isting cell phone display. In preparation

for the test, pieces of the cover slip were

mounted on edge in epoxy and polished

to a smooth finish. Samples were then

coated with a thin layer of conductive

carbon to counter the unwanted charge

accumulation.

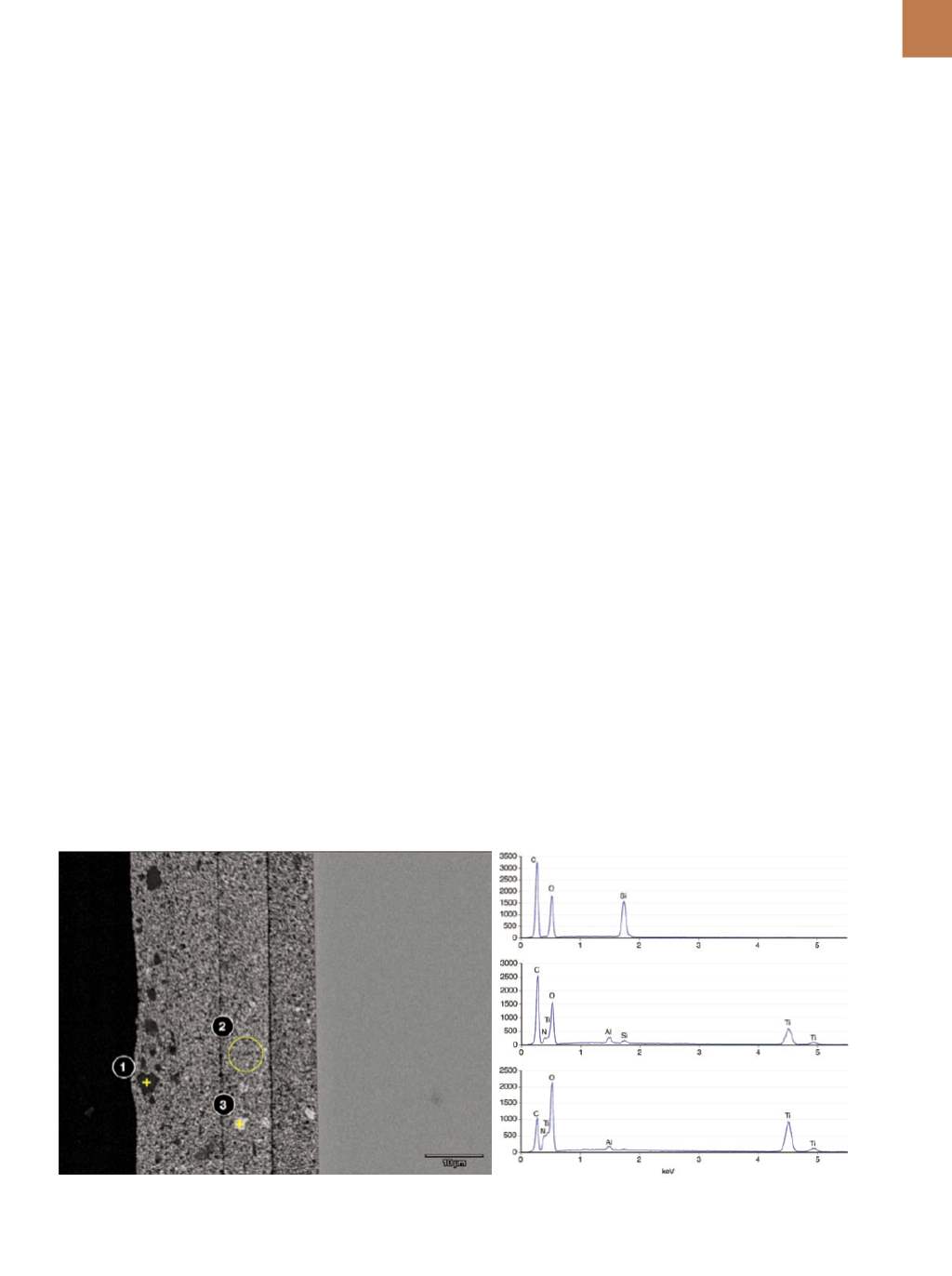

An electron image of the cover slip

is shown in Fig. 1 along with composi-

tional spectra from three selected ar-

eas. Typical of EDS spectra, the graphs

have a low-intensity background with

a few sharp peaks characteristic of spe-

cific elements. System software can

usually identify most peaks in a given

spectrum, and often provides the op-

tion of charting intensities as simple

counts, weights, or atomic percentages.

another version emerged that takes ad-

vantage of a sensing mechanism based

on fully depleted high-resistivity silicon.

These newer devices, called silicon-drift

detectors (SDDs), have very low leakage

current and can therefore operate close

to room temperature. Besides elimi-

nating the need for cryogenic cooling,

SDDs are also faster, more scalable, and

available in a wider range of sizes.

Using energy dispersive x-ray

spectroscopy to analyze cell phone cov-

er glass—even with the improvements

in detector technology—still requires

a fair amount of caution and care. For

one thing, cover glass contains sodium

ions that can become mobile when ex-

posed to a strong electron beam. Any

subsequent changes in composition

could lead to false measurements if not

accounted for. Cover glass is also non-

conductive and must be modified to

prevent unwanted buildup of charge

during scans. This is typically done by

coating the test sample with a thin layer

of conductive material such as carbon,

iridium, or another metal. Even then,

it is still possible for residual charge to

accumulate beneath the coating if the

electron beam intensity is not carefully

monitored.

GET THE DRIFT

Silicon drift detectors effectively

mitigate many of the challenges pre-

sented by cell phone cover glass be-

cause they work faster and at lower

beam currents than other detector

types. SDDs with digital pulse proces-

sors operate with much less overhead

than Si(Li) detectors, achieving signifi-

cantly higher x-ray count rates. Today’s

silicon drift detectors can easily reach

rates of 50,000 to 100,000 counts per

second if sufficient signal is provided

and if the sample can withstand the in-

tensity of beam current exposure. Sil-

icon-lithium versions, by comparison,

are limited to about 3000 counts per

second.

SDDs are also available in sizes of

up to 100 mm

2

or more, which is any-

where from three to 10 times larger

than Si(Li) detectors. And unlike their

predecessors, SDDs see little degrada-

tion in resolution as their active area

is increased. In fact, the largest SDDs

are rectangular in shape, which allows

them to get closer to the test sample

where they can capture more x-ray sig-

nal for a given beam intensity.

The bottom line for manufacturers

of cell phone cover glass is that, with

the right SDDs, they can now obtain

detailed compositional information

about their products without having

to crank up beam intensity to where

it could damage or alter the test sam-

ple—and they can do it in a fraction of

the time that it would have taken in the

past. Where Si(Li) detectors might need

almost two minutes to acquire a single

Fig. 1

– Electron image of glass cover slip cross section revealing surface layers and glass substrate. The three spectra were acquired from the

indicated locations in the surface coatings.

#1

#2

#3