A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y / J U N E 2 0 1 7

3 0

a carbon-rich binder. The smallest dis-

cernable particles are roughly 100 nm

in diameter.

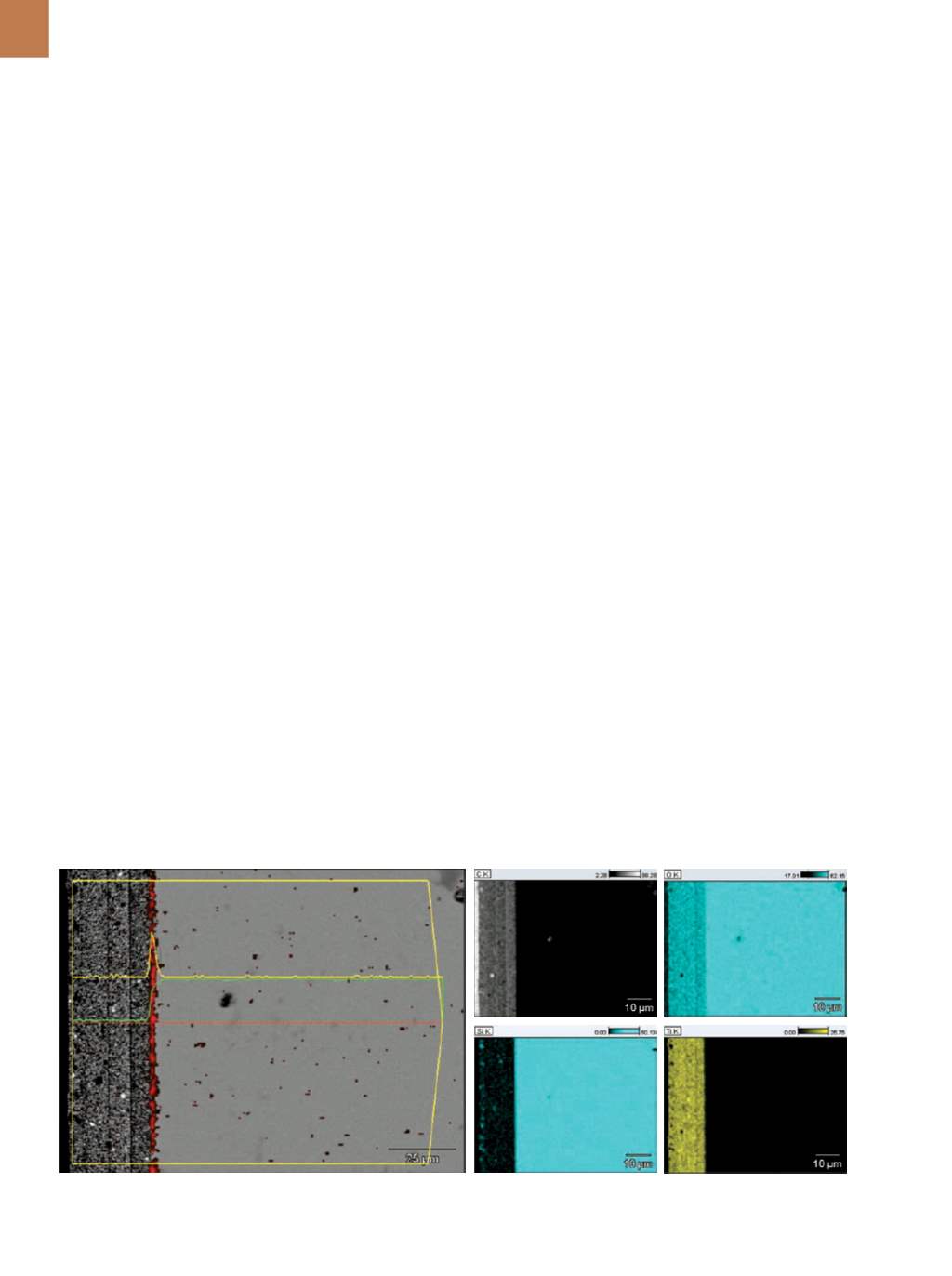

X-ray maps of the cell phone glass

are shown in Fig. 4. As before, left-to-

right line profiles for sodium and po-

tassium are superimposed on the SEM

image. It is clear that sodium and po-

tassium are distributed differently in

the two samples. In the glass slip, po-

tassium is concentrated at the surface

of the substrate, but in the phone glass,

it is observed in high levels to a depth of

more than 25 microns—indicative of a

wider region of ion-exchange strength-

ening. The sodium concentration, as

expected, rises as the potassium con-

centration falls. Note that there is little

or no change in the appearance of the

glass in the electron image, indicating

the presence of the potassium-rich re-

gion. Without EDS analysis, the depth,

intensity, and shape of the enhanced

potassium region would have gone

unnoticed.

The silicon map in the lower left

quadrant of the small image group re-

veals the presence of silicon (apparent-

ly SiO

2

particles) in the first of the four

coating layers. Titanium is distribut-

ed evenly throughout the layers as are

carbon, oxygen, and nitrogen. No oth-

er major constituent or particle was

found.

In the SEM image, the cover slip

surface is oriented to the left. The black

area is the epoxy and to the right of that

are four surface layers followed by the

glass substrate. The bright particles

scattered throughout the top layers

are found to be rich in titanium and the

darker particles rich in silicon. In this

type of image, the brighter the area, the

larger the average atomic number of

the sample.

Based on the analysis, the surface

coatings consist primarily of titanium,

carbon, oxygen, and nitrogen. The large

dark particles embedded in the top lay-

er are most likely composed of silicon

dioxide. If there were any contaminants

or inclusions in the sample, they would

be visible in the image.

DELVING DEEPER

A similar image of the cover slip

along with a corresponding x-ray map is

shown in Fig. 2. The map was acquired

by scanning the electron beam across

the sample and capturing x-ray spectra

at each node of an imaginary grid. The

procedure is automated and can find

the distributions of all measurable ele-

ments without knowing their identities

in advance. During the procedure, a live

view of the map is displayed. Afterward,

the spectra can be processed to reveal

additional sample details.

The red overlay on the SEM image

in Fig. 2, a potassium distribution map,

is an example of such post-processing.

It reveals a thin layer of potassium,

about one micron thick, at the surface

of the glass. The layer is rather nonuni-

form, alternating between areas of high

concentration and areas with no po-

tassium at all. Silicon-rich areas (likely

SiO

2

) are visible in the topmost layer,

while titanium, oxygen, and carbon are

distributed throughout.

Sodium and potassium distribu-

tion profiles were also extracted from

the test data and are included as over-

lays on the sample image. The yellow

trace represents potassium, while the

green trace is sodium. Note how sodi-

um concentration drops where potas-

sium peaks. The potassium line scan

was extracted from the full width of the

map; each point represents a vertical

column, which has an averaging effect

on variances in concentration.

SCREEN TEST

The other sample selected for the

demonstration is a piece of screen glass

from an actual cell phone. Like the cov-

er slip, it was mounted, polished, and

coated prior to scanning. An SEM im-

age and three compositional spectra

are shown in Fig. 3. As before, the sur-

face is oriented to the left and there are

four layers topping the substrate. The

surface layers again contain particles of

what appears to be SiO

2

and combina-

tions of titanium, nitrogen, oxygen, and

Fig. 2

– Electron image and EDS maps from the glass cover slip cross section. Overlaid on the electron image are extracted line scans for potassium

and sodium and the potassiummap.