A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

N O V E M B E R / D E C E M B E R

2 0 1 6

6 1

FEATURE

11

undergoing maintenance after a fixed time (Fig. 7). This

often results in suboptimal operation, with furnaces under-

going maintenance too early or too late. In the Industry 4.0

framework, sensing capability for furnace temperature-time

response is needed, such as the heat-up response cycle after

a charge is loaded, together with skin temperature moni-

toring. Connectivity and analytics capability would help to

identify influencing parameters, such as charge and basket

weight, to provide intelligence capability for burner health.

This would trigger furnace and burner maintenance require-

ments to create value in terms of proactivemaintenancewith

efficient operation and energy reduction. The Industry 4.0

framework also provides architecture to connect the mainte-

nance staff through appropriate alert systems, either through

a computer systemor mobility and wearable solutions.

CONCLUSION

Industry 4.0 is in the early technology evolution stage

with tremendous business expectations and significant

research grants available to pursue the technology. Few orga-

nizations have taken the lead in identifying cases for using and

applying this technology, while the IT infrastructure is nearly

ready to be implemented. The challenge lies in identifying val-

ue-driven use cases, which could impact efficiency and prod-

uct cost and quality. In the area of heat treating, an additional

challenge will be finding talent with a deep understanding of

physical metallurgy and the industrial heat treating domain,

in addition to the ability to convert this understanding into

analytics, algorithms, and self-learning intelligence that lever-

age IT systems. The immediate need for the future of this

emerging technology is development of such interdisciplinary

engineering skillsets (Fig. 8), which couldbe the biggest obsta-

cle to successful scale-up of this technology.

~HTPro

For more information:

SatyamS. Sahay is a John Deere Fel-

low, materials engineering, John Deere Technology Center

India, John Deere India Pvt. Ltd., Tower XIV, Cybercity, Mag-

arpatta City, Pune 411 013, India,

satyamsahay@yahoo.com.

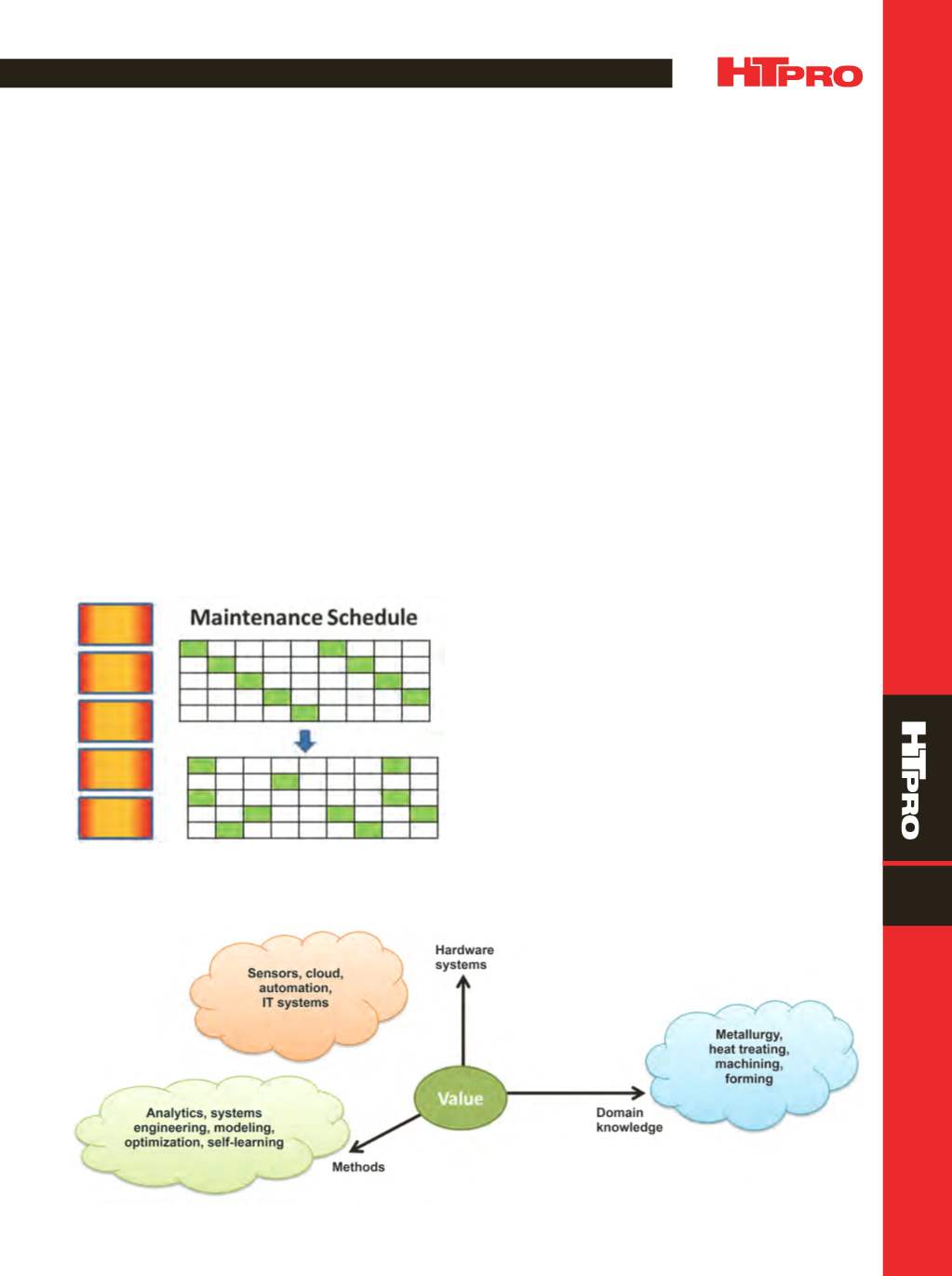

Fig. 7 —

Time-based, staggered furnace maintenance schedule,

which has a significant impact on efficiency if transformed into a

furnace health-based schedule.

Fig. 8 —

Interdisciplinary skills needed to successfully leverage Industry 4.0 in the context of heat treating.

health, machining steps prior to carburizing could be fine-

tuned to anticipate distortion and better manage distortion

in the final product. Furthermore, depending on the location

of the part in the carburizing step, finishing operations could

bemade part specific, thereby having highly predictable dis-

tortion in the product. In the Industry 4.0 framework, sensing

capability is required for:

•

Composition information

•

The health of both furnace and oil-quench tank

•

Part location

•

Connectivity and analytics capability to predict hard-

enability and distortion

•

Intelligence capability to fine-tune recipes based on

instantaneous inputs

•

Operating conditions

•

Deriving location-specific finishing conditions to

create value in terms of mitigating distortion in preci-

sion components

Furnace maintenance:

In a heat treating shop with a

battery of furnaces, the maintenance schedule is designed

predominately on a time interval, with specific furnaces